Copolymer and its preparation method and reverse osmosis membrane protective agent comprising the copolymer and its uses

A reverse osmosis membrane and copolymer technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., to achieve the effects of reducing eutrophication pollution, no fouling, and low phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

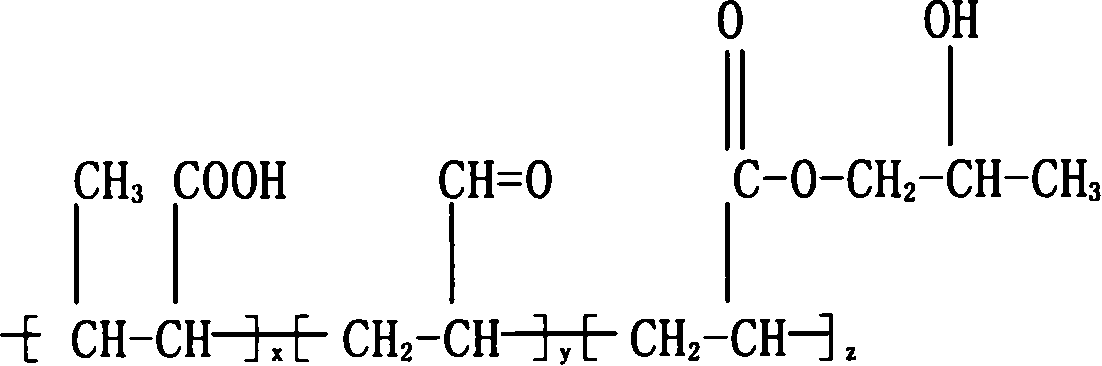

[0034] Preparation of crotonic acid-acrolein-hydroxypropyl acrylate copolymer.

[0035] First take by weighing 170 kilograms of crotonic acid, 7 kilograms of sodium hypophosphite, 7 kilograms of ammonium persulfate, 50 kilograms of acrolein, and 200 kilograms of hydroxypropyl acrylate for subsequent use. Then crotonic acid is sucked into two layers of crotonic acid dripping tanks with a vacuum pump; sodium hypophosphite is dissolved in water to 40 kg for subsequent use; The aldehyde is inhaled into the two-layer acrolein dropping tank with a vacuum pump; the hydroxypropyl acrylate is sucked into the two-layer hydroxypropyl acrylate dropping tank with a vacuum pump; 194 kg of water is added to the reaction kettle.

[0036]Then turn on the condenser valve, cooling pump, and reactor stirring paddle switch; open the steam valve to heat the water in the reactor to 68±2°C, and add the prepared sodium hypophosphite aqueous solution. Continue to raise the temperature to 72±2°C and ke...

Embodiment 2

[0040] Repeat embodiment 1, have following difference: take by weighing 160 kilograms of crotonic acid. Pass into cooling water in the reactor jacket, make material temperature drop to 45 ℃, then take 10 grams of material and measure solid content, record solid content to be 72.84%. According to its solid content, 300 kg of water was added into the reactor to obtain a crotonic acid-acrolein-hydroxypropyl acrylate copolymer with a solid content of 50.7%.

[0041] The copolymer obtained by this method, its average molecular weight: 128 600; pH value (1% aqueous solution): 1.84; Density: 1.29g / cm 3 ; Intrinsic viscosity at 30°C: 0.092dl / g.

Embodiment 3

[0043] Repeat embodiment 1, have following difference: take by weighing 160 kilograms of crotonic acid, 190 kilograms of hydroxypropyl acrylate. Pass into cooling water in the reactor jacket, make material temperature drop to 45 ℃, then take 10 grams of material for solid content measurement, record solid content to be 72.73%. According to its solid content, 300 kg of water was added into the reactor to obtain a crotonic acid-acrolein-hydroxypropyl acrylate copolymer with a solid content of 50.4%.

[0044] The copolymer obtained by this method, its average molecular weight: 118 100; pH value (1% aqueous solution): 2.06; Density: 1.22g / cm 3 ; Intrinsic viscosity at 30°C: 0.084dl / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com