Slow releasing microsphere preparation of Thymopentin, and prepartion method

A slow-release microsphere preparation and thymus technology, which is applied in pharmaceutical formulations, peptide/protein components, medical preparations containing active ingredients, etc., can solve problems such as low bioavailability, different courses of treatment, and loss of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

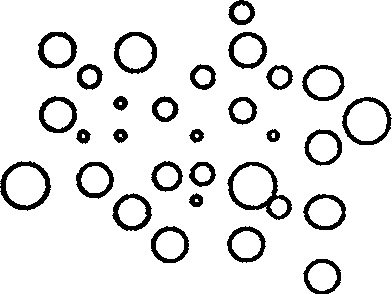

[0026] exist figure 1 In the process, the O phase is weighed according to the proportion and added to the W1 phase, and the crusher is used for thorough crushing. Through microscopic observation, the formation of figure 1 The transparent unstable spherical microspheres in the W1 / O phase.

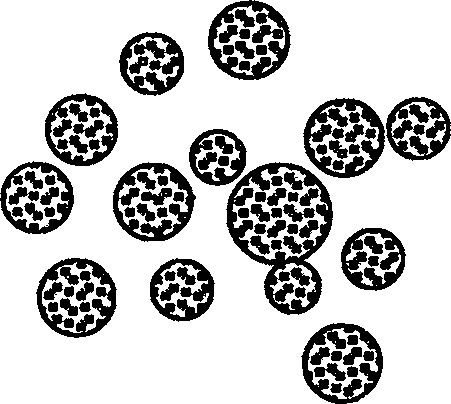

[0027] exist figure 2 In the experimental example shown, the W1 / O phase was slowly and uniformly injected into the high-speed stirring W2 with a syringe. After the final clathrate, the sample was taken and observed through a microscope. It can be observed that the W1 / O / W2 phase is an opaque spherical microstructure. The diameter of the microsphere is obviously larger than that of the W1 / O phase.

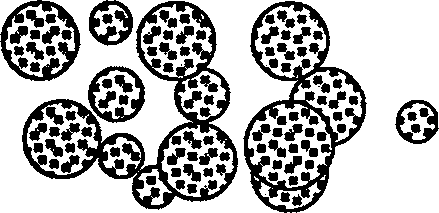

[0028] exist image 3 In another experimental example shown, W1 / O / W2 microspheres are aged by a rotary evaporator to evaporate methylene chloride, the collected microspheres are added with excipients, and a specific lyophilization curve is applied in a lyophilizer Microscopic observation of th...

experiment example 2

[0029] Experimental Example 2: Release of Lactide-Glycolide Copolymer

[0030] See Figure 4 , Figure 5

Description of drawings:

[0031] figure 1 It is a structural diagram of the W1 / O phase of the present invention.

[0032] figure 2 It is the structure diagram of W1 / O / W2 phase.

[0033] image 3 Structural diagram of microspheres.

[0034] Figure 4 Release curve of PLGA50 / 50

[0035] Figure 5 Release curve of PLGA65 / 35

Embodiment 1

[0037] Thymopentin 7.5g Lactide-glycolide copolymer (PLGA) 40g

[0038] Gelatin 0.75g D-mannitol 0.75g

[0039] Thymopentin was fully dissolved in water to make water phase W1, lactide-glycolide copolymer (PLGA) was fully dissolved in dichloromethane to make oil phase O; polyvinyl alcohol (PVA) was fully dissolved in water to make Form water phase W2; add oil phase O to water phase W1, emulsify to form W1 / O phase, then slowly inject into water phase W2 at a uniform speed to form W1 / O / W2 phase, evaporate through rotary evaporation Organic solvent dichloromethane, collect the microspheres, use a specific freeze-drying curve to freeze-dry, and finally make 1000 thymopentin sustained-release microspheres for injection, with a particle size of 1-100um. One injection per month, 4 to 5 mg per injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com