Treatment method for waste water containing high content calcium and organic matter

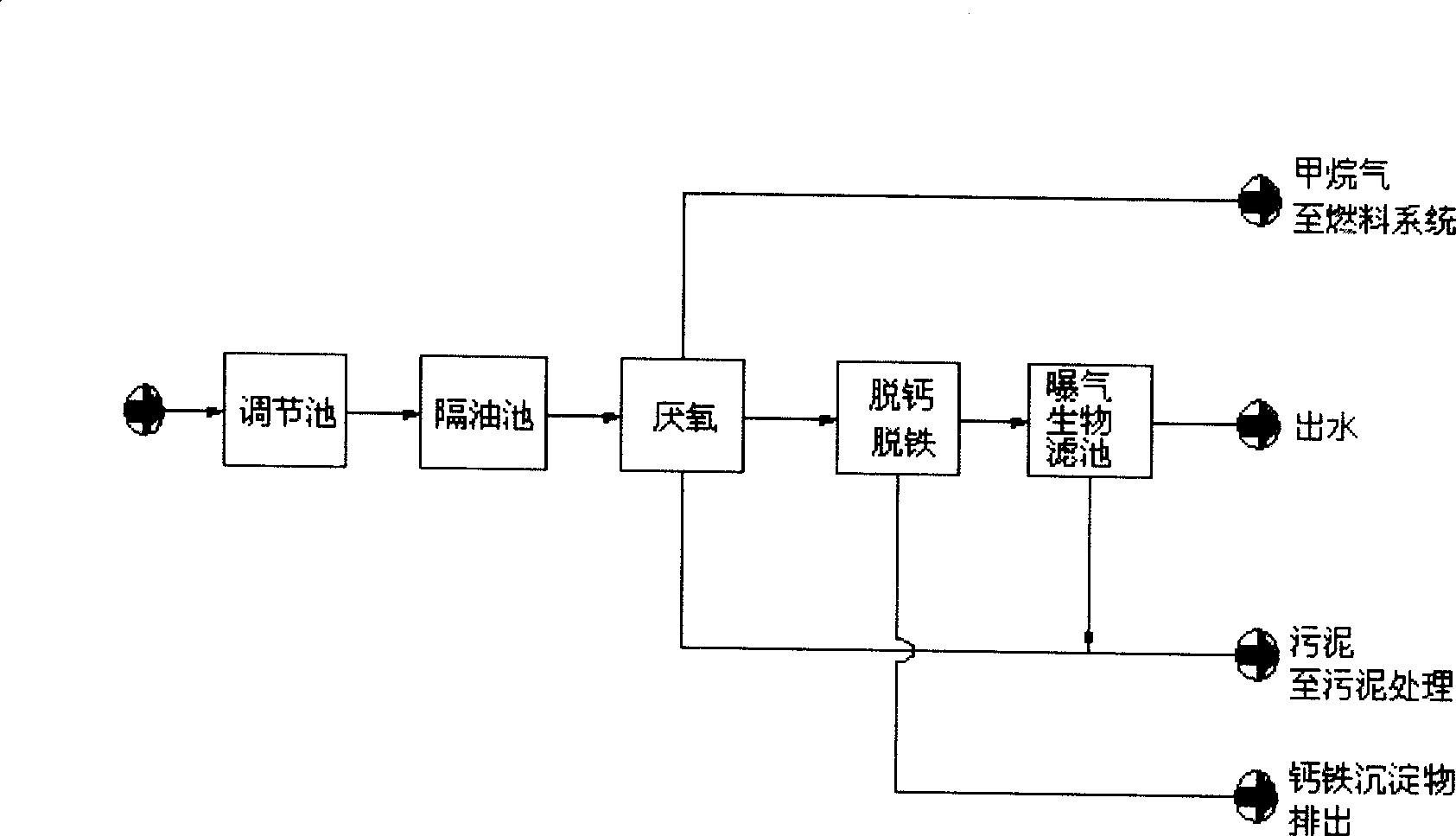

A treatment method and wastewater treatment technology, applied in water/sewage treatment, sustainable biological treatment, neutralized water/sewage treatment, etc., can solve the problems of poor practicability, large equipment investment, high operating costs, and achieve a small footprint. , The effect of dealing with high organic matter load and high decalcification and iron removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] High concentration wastewater (COD cr The value is 12000mg / L, the calcium content is 5000mg / L, and the iron content is 250mg / L), after oil separation treatment, it is pumped into the anaerobic reactor (EIC), the operating temperature is 30°C, the hydraulic retention time is 32h, COD Volume load 7.2KgCOD / m 3 .d, adjust the pH of the anaerobic effluent to 7, then add 25mg / L decalcification and deiron softening agent for softening treatment (the softening agent consists of 5% by weight sodium polyacrylate, 85% by weight of aluminum sulfate, 10% by weight of peroxide Hydrogen), the sedimentation effluent is sent to the biological aerated filter for aerobic treatment, in which the hydraulic retention time of the primary biological aerated filter is 6.5h, and the COD volume load is 4.8KgCOD / m 3 .d, the hydraulic retention time of the secondary biological aerated filter is 6.5h, and the COD volume load is 2.9KgCOD / m 3 .d. Final effluent quality: COD cr The calcium content ...

Embodiment 2

[0021] High-concentration wastewater (COD value is 20000mg / L, calcium content is 4000mg / L, iron content is 100mg / L), after oil separation treatment, it is pumped into the decalcification and iron softening tank for softening treatment, and the pH of the effluent is adjusted to 8. Add 15mg / L decalcification and iron removal softener (the softener consists of 50% by weight diallylamine chloride / acrylamide copolymer, 50% by weight ferric chloride), and after sedimentation, the supernatant is sent to the anaerobic In the oxygen reactor (EIC), the operating temperature is 35°C, the hydraulic retention time is 20h, and the COD volume load is 12KgCOD / m 3 .d, the anaerobic effluent is sent to the biological aerated filter for aerobic treatment, in which the hydraulic retention time of the primary biological aerated filter is 6.5h, and the COD volume load is 8KgCOD / m 3 .d, the hydraulic retention time of the secondary biological aerated filter is 6.5h, and the COD volume load is 4.8KgC...

Embodiment 3

[0023] High-concentration wastewater (COD value is 20000mg / L, calcium content is 4000mg / L, iron content is 150mg / L), after oil separation treatment, it is pumped into the decalcification and iron softening tank for softening treatment, and the pH of the effluent is adjusted to 8. Add 5mg / L decalcification and deferrification softener (the softener consists of 90% by weight polydimethyldiallyl ammonium chloride, 5% by weight ferric chloride, 5% by weight potassium permanganate), and put The supernatant is sent to the anaerobic reactor (EIC), the operating temperature is 40°C, the hydraulic retention time is 32h, and the COD volume load is 18KgCOD / m 3 .d, the anaerobic effluent is sent to the biological aerated filter for aerobic treatment, in which the hydraulic retention time of the primary biological aerated filter is 4h, and the COD volume load is 6KgCOD / m 3 .d, the hydraulic retention time of the secondary biological aerated filter is 4h, and the COD volume load is 4KgCOD / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com