Full coated high pentration type brightening optical module suitable for liquid crystal display

A technology of liquid crystal display and optical components, which is applied in the field of high-transmittance brightening optical components, which can solve the problems of not having the function of light polarization state conversion and light recovery mechanism to enhance brightness, and achieve the reduction of resources required for production and cost reduction , The effect of saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

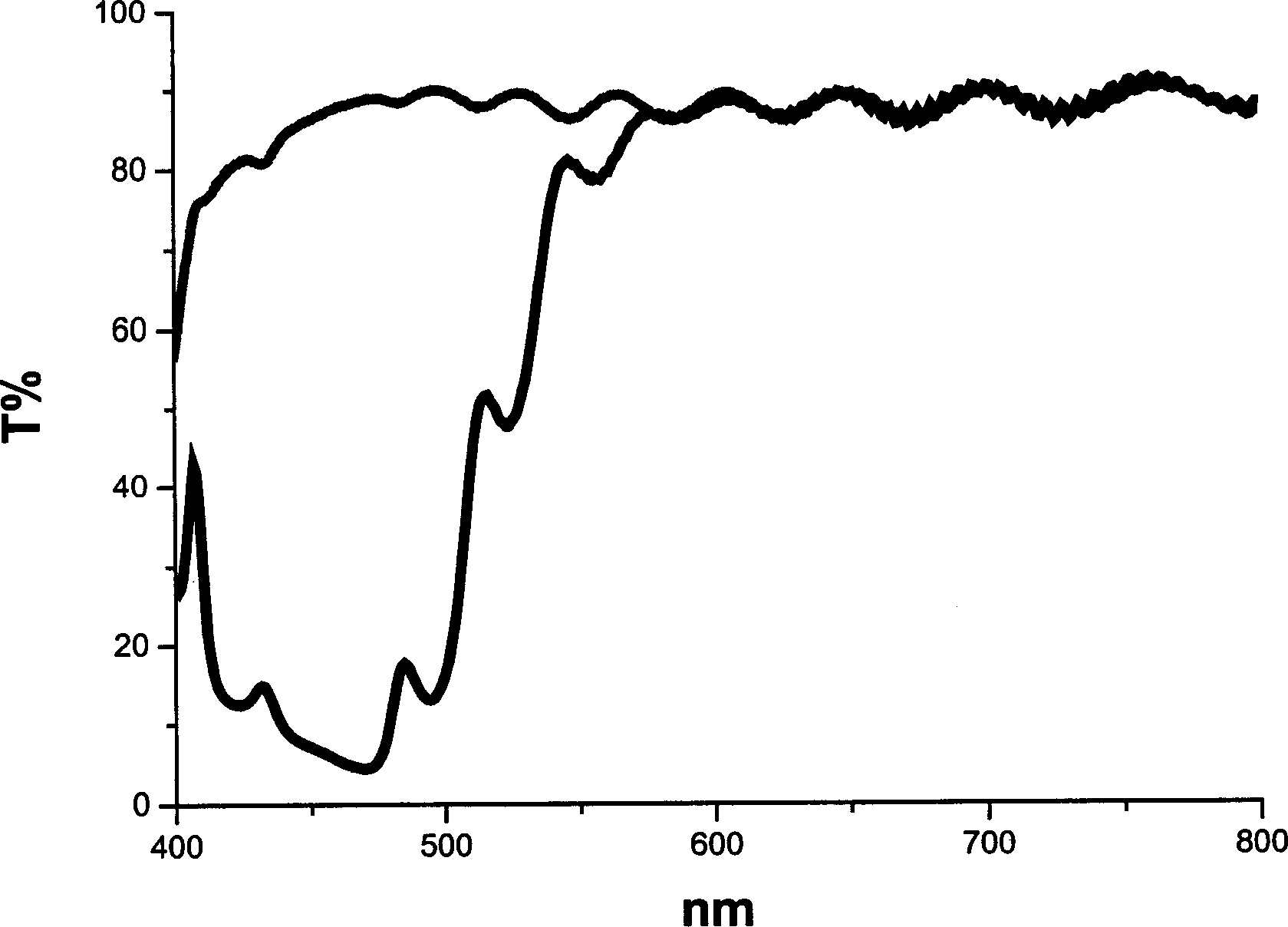

[0018] Polymerizable cholesteric liquid crystals SLM 90032 and SLM 90034 were formulated into a 25wt% solution with SLM 90032:SLM 90034=70:30 ratio and toluene (Toluene), and at the same time, 1wt% of UV light-enabling agent Irgacure 907(R) (Ciba Geigy) was added , and then coated on the aligned PET film with a thickness of 50 μm, dried at 80°C for 2 minutes, and then used 100W / cm 2 After 20 seconds of irradiation with a special UV lamp, a film is formed, and finally a cholesteric phase liquid crystal film with a film thickness of about 5 μm is obtained.

[0019] The polymerizable liquid crystal SLM 90519 and toluene (Toluene) were formulated into a 10wt% solution, and 1wt% of UV light initiator Irgacure 907(R) was added at the same time. Apply this solution on the above-mentioned cholesteric liquid crystal film, dry it at 80°C for 1 minute, and use 100W / cm 2 A film with a thickness of 2 μm is formed after being irradiated with a UV lamp for 20 seconds, thus completing the pa...

Embodiment 2

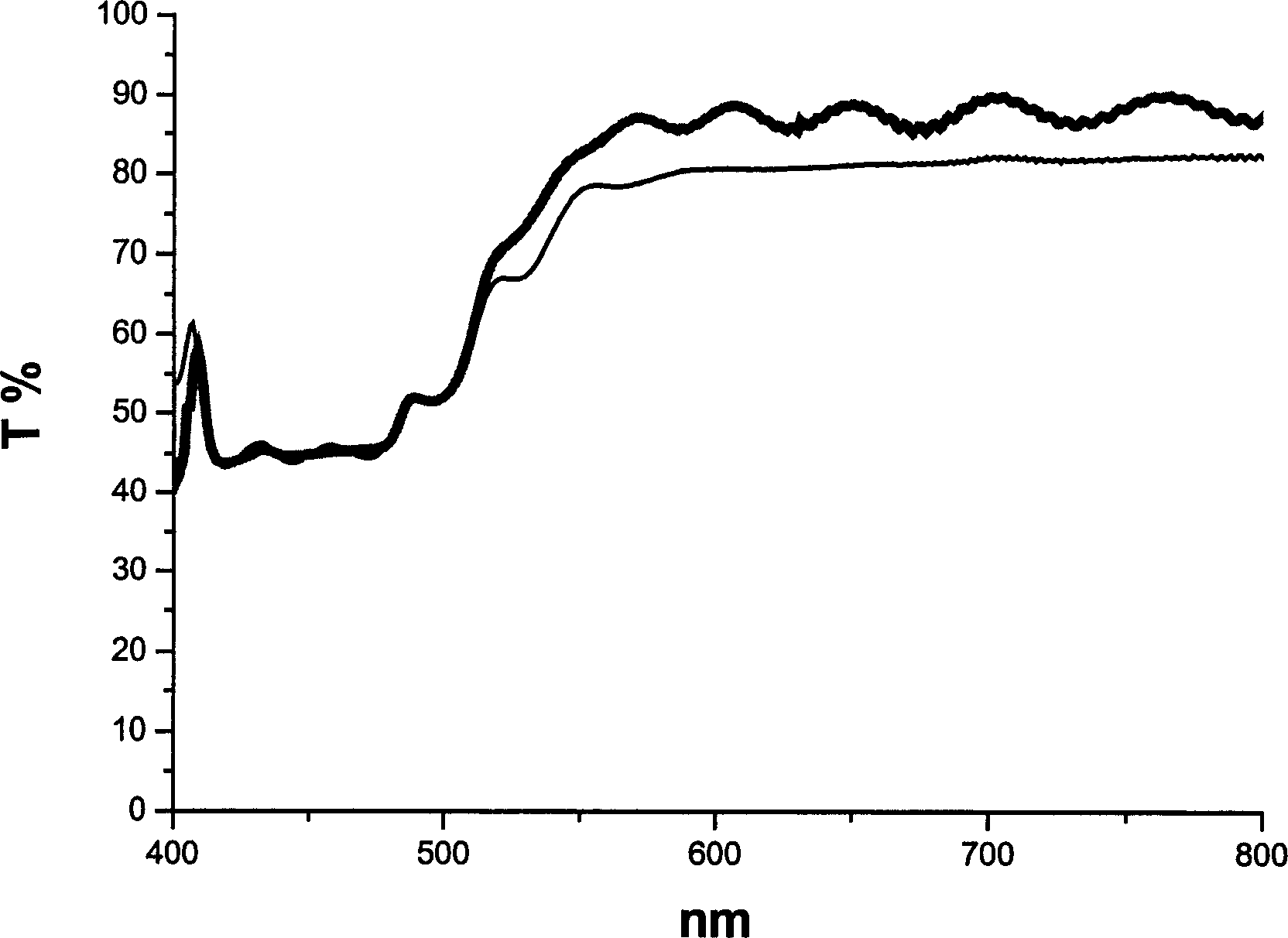

[0024] A brightness-enhancing optical assembly integrated with a polarizing film was prepared by using the brightness-enhancing optical assembly prepared in Example 1. First confirm the optical axis direction of the above-mentioned 1 / 4 wavelength retarder, and apply the following solution in the direction of its optical axis at an angle of 45 degrees: make a 20wt% solution of polymerizable liquid crystal SLM 90519 and toluene (Toluene), and add 1 wt% UV light initiator Irgacure 907(R) and 3 wt% black dichroic dye. After drying at 80°C for 2 minutes, use 100W / cm 2 A film with a thickness of 2 μm is formed after being irradiated with a UV lamp for 1 minute, which is the part of the polarizer in the brightness-enhancing optical component.

[0025] The brightness-enhancing optical component manufactured in the above-mentioned way has a thickness of only about 59 μm, and it has the characteristics of brightness enhancement and high penetration when placed on a backlight LCD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com