Use of Dimashg process in production of integrated circuits

An integrated circuit and process technology, which is applied in the field of integrated circuit manufacturing with Damascus technology, can solve the problems of complex etching process, adverse reactions in the subsequent process, cumbersome process, etc., to reduce the occurrence of filling defects, reduce capacitance, and simplify the process required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Now in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

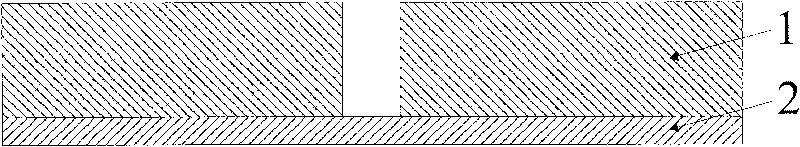

[0037] Firstly, a through-hole dielectric layer 1 at the bottom layer of damascene is deposited.

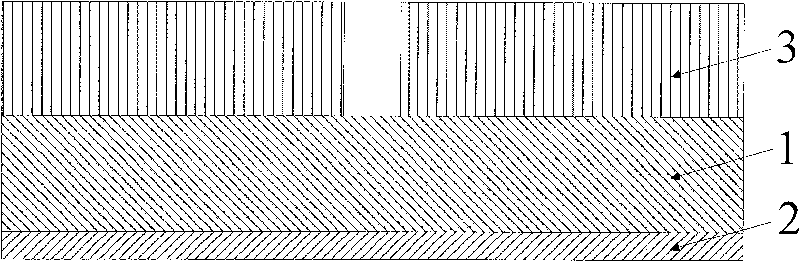

[0038] Secondly, if Figure 3A as shown ( Figure 3A For the schematic diagram of coating the first single-layer photosensitive material), the first layer of single-layer photosensitive material 3 is coated on the surface of the through-hole dielectric layer of the damascene bottom layer, and photolithography is performed. The first single-layer photosensitive material is composed of ketones, ethers, alkane organic solvents and photosensitive cross-linking resins, and the molecular weight is between 85,000 and 150,000.

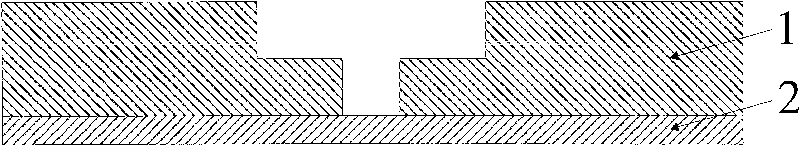

[0039] Secondly, if Figure 3B as shown ( Figure 3B is a schematic diagram of through-hole etching), and through-hole etching and cleaning are performed on the bottom layer of the Damascus through-hole dielectric layer. The et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com