Method for treating phenol-contained waste water by anaerobic-aerobic coupled biological fluidizing bed

A biological fluidized bed, anaerobic and aerobic technology, applied in the direction of aerobic and anaerobic treatment, can solve the problems of long residence time, large floor area, low treatment efficiency, etc. Small area, the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Microbial Phase in a Macroporous Suspension Carrier

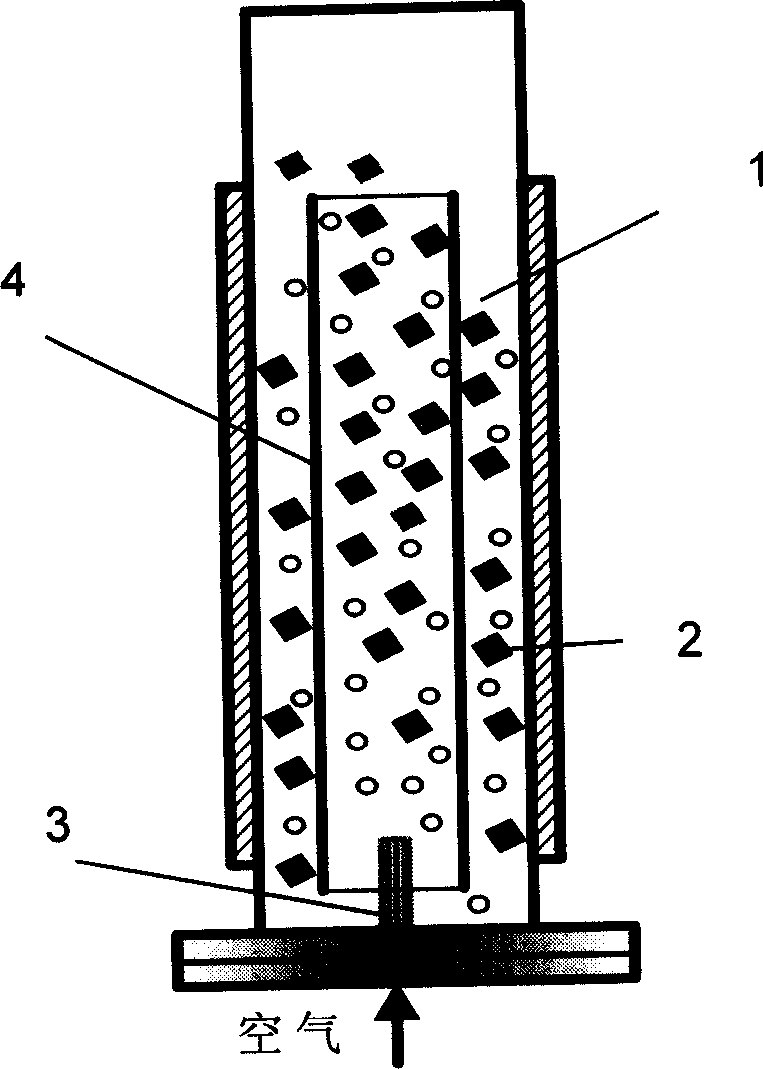

[0038] Fluidized bed type: air-lift internal circulation biological fluidized bed; effective volume: 19L

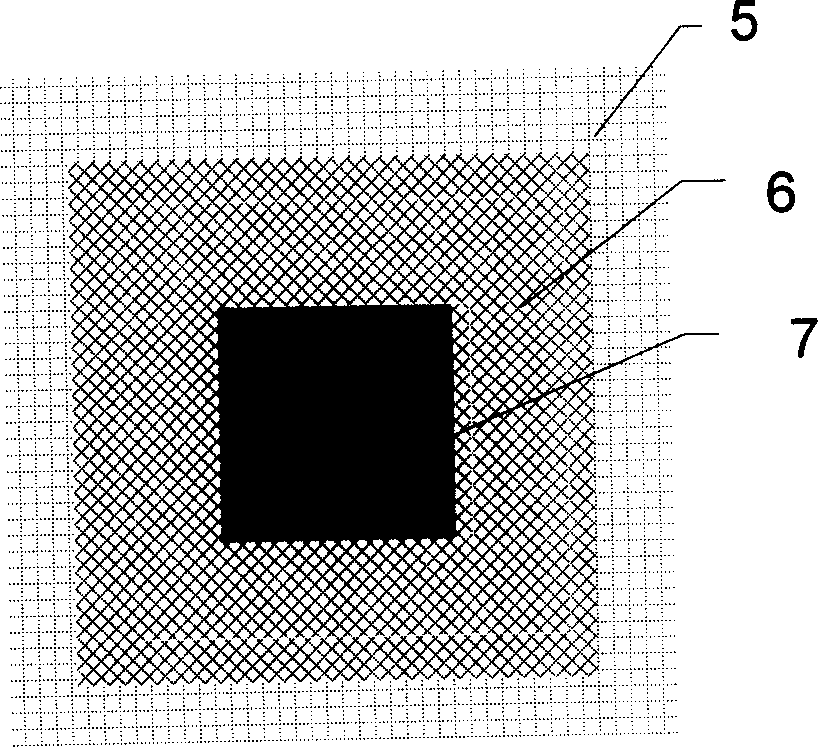

[0039] Carrier material: polyurethane; the volume ratio of the carrier dosage to the effective volume of the reactor: 1%

[0040] Carrier size: 15mm×15mm×15mm; Carrier aperture: 1.25mm; Porosity: 95%; Minimum one-dimensional size: 15mm Sludge source: Secondary sedimentation tank sludge of wastewater treatment plant

[0041] a. The wastewater first enters the regulating tank, and according to the ratio of various nutrients in the water, nitrogen salts, phosphorus salts and nutrient salts are added, and the pH of the wastewater is adjusted to about 7.0;

[0042] b. The adjusted wastewater enters the biological fluidized bed containing the macroporous suspension carrier for aeration, and realizes the degradation of wastewater through anaerobic-aerobic coupling biological treatment;

[0043] c. After an...

Embodiment 2

[0046] Embodiment 2: sequencing batch type activated sludge process

[0047] Fluidized bed type: air-lift internal circulation first-stage biological fluidized bed; effective volume: 19L

[0048] Carrier material: polyurethane; the volume ratio of the carrier dosage to the effective volume of the reactor: 30%;

[0049] Carrier size: 10mm×10mm×8mm; Carrier aperture: 0.5mm; Porosity: 80%; Minimum one-dimensional size: 8mm Processing cycle: 12h

[0050] a. The wastewater first enters the regulating tank, and according to the ratio of various nutrients in the water, nitrogen salts, phosphorus salts and nutrient salts are added, and the pH of the wastewater is adjusted to about 8.0;

[0051] b. The adjusted wastewater enters the biological fluidized bed containing the macroporous suspension carrier for aeration, and realizes the degradation of wastewater through anaerobic-aerobic coupling biological treatment;

[0052] c. After anaerobic and aerobic coupling treatment, the efflue...

Embodiment 3

[0055] Embodiment 3: sequencing batch activated sludge process

[0056] Fluidized bed type: air-lift internal circulation first-stage biological fluidized bed; effective volume: 19L

[0057] Carrier material: polyurethane; the volume ratio of the carrier dosage to the effective volume of the reactor: 5%

[0058] Carrier size: 25mm×25mm×25mm; Carrier aperture: 1.25mm; Porosity: 95%; Minimum one-dimensional size: 25mm Processing cycle: 24h

[0059] a. The wastewater first enters the regulating tank, and according to the ratio of various nutrients in the water, nitrogen salts, phosphorus salts and nutrient salts are added, and the pH of the wastewater is adjusted to about 8.5;

[0060] b. The adjusted wastewater enters the biological fluidized bed containing the macroporous suspension carrier for aeration, and realizes the degradation of wastewater through anaerobic-aerobic coupling biological treatment;

[0061] c. After anaerobic and aerobic coupling treatment, the effluent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com