Lyotropic liquid crystal polarizing film and preparation method thereof

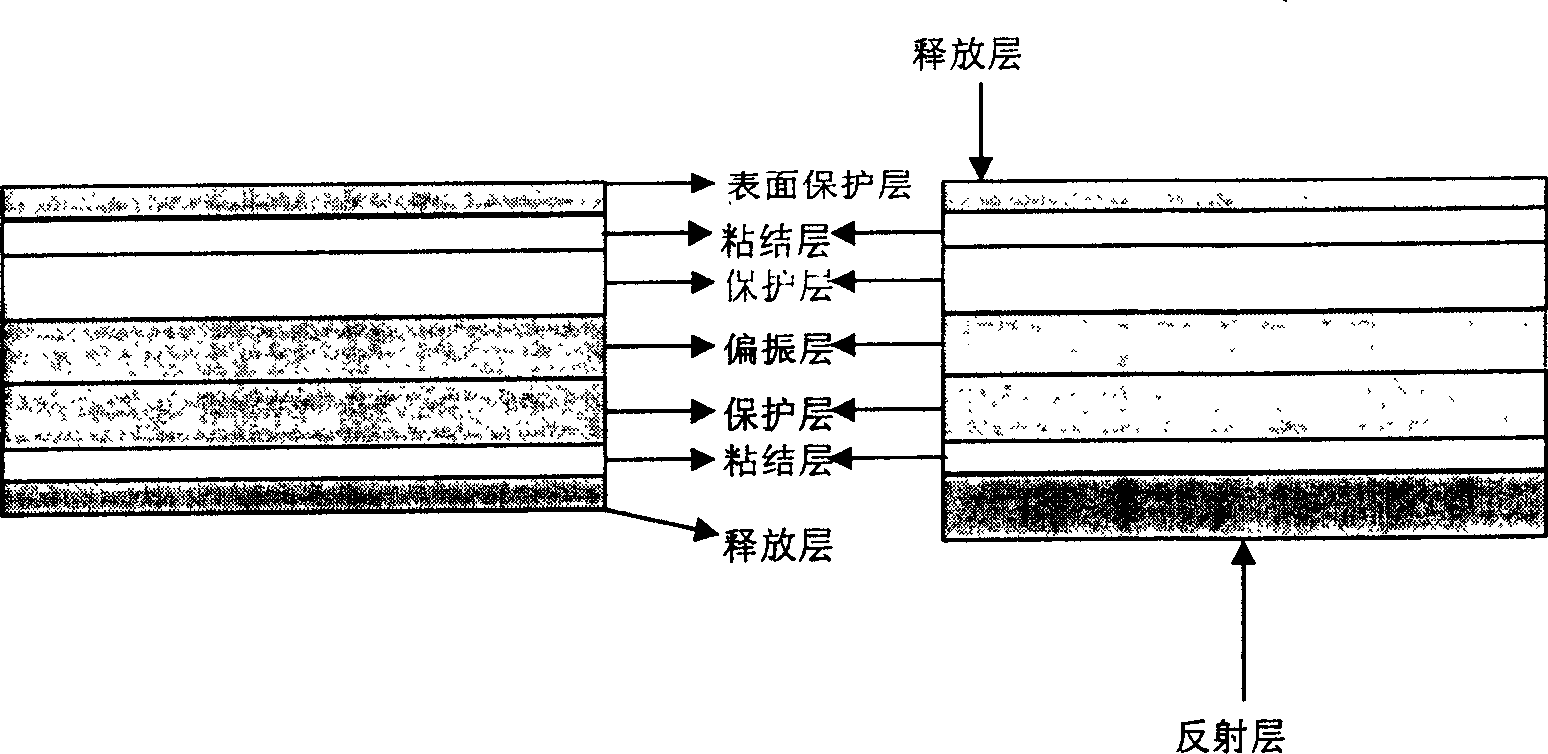

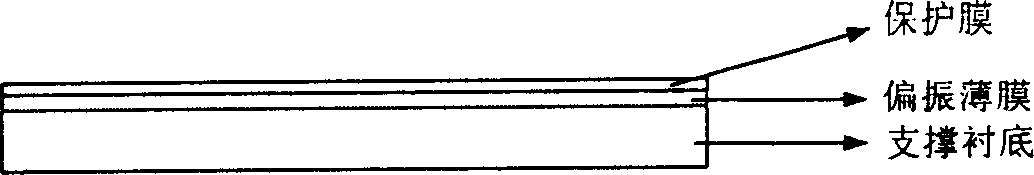

A lyotropic liquid crystal and polarizing film technology is applied in the field of lyotropic liquid crystal solid-state polarizing film and its preparation, which can solve the problems of poor moisture and heat resistance, low heat resistance temperature, and poor optical uniformity, and achieves excellent moisture and heat resistance and heat resistance. The effect of high temperature and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Mix the reduced dark blue BO with a molar ratio of 1:20 and fuming sulfuric acid (concentration is 20% by mass), heat to 110 ° C, and keep it warm for 36 hours, then cool to room temperature, pour it on ice cubes to precipitate, and then put the ice on the ice. The analyzed solution was vacuum-filtered under reduced pressure, washed with absolute ethanol and deionized water until there were no sulfate ions in the filtrate, and dried to obtain sulfonated reduced dark blue BO.

[0046] Dissolve 2g of sulfonated reduced dark blue BO in 500ml of distilled water, vacuum and filter under reduced pressure with an acid-resistant filter funnel with a filter hole of 3 to 5 microns, then heat and evaporate the solution to a 12.5% solution, cool to room temperature, and obtain a structurally ordered Sulfonated reduction dark blue BO lyotropic liquid crystal phase.

[0047] Before coating, the glass substrate is cleaned with Piranha solution (prepared by mixing concentrated sulfur...

Embodiment 2

[0051] Mix 0.2 mol of Vat Blue RSN with 2 mol of fuming sulfuric acid (concentration is 20% by mass) and 1 mol of chlorosulfonic acid, heat to 95°C, keep warm for more than 72 hours, cool to room temperature, pour it on ice cubes to precipitate, and The ice-out solution was vacuum-filtered under reduced pressure to obtain a blue filter cake.

[0052] Disperse the blue filter cake, add 250ml of concentrated hydrochloric acid (concentration 36-38% by mass), oscillate ultrasonically for 1.5 hours, then heat to 100°C, keep it warm for 2 hours, cool, and filter with an acid-resistant filter with a filter hole of 5-7 microns The funnel was vacuumed and filtered under reduced pressure, washed with concentrated hydrochloric acid until the filtrate was free of sulfate ions, and dried to obtain sulfonated reduced blue RSN powder.

[0053] Add 0.5 g of sulfonated vat blue to 100 ml of distilled water, stir electromagnetically for 2 hours, filter, evaporate and concentrate by heating to o...

Embodiment 3

[0056] Mix 1 mol of reduced scarlet GG with 12 mol of oleum (concentration: 20% by mass), heat to 70° C. and keep it warm for 12 hours, cool to room temperature, pour it on ice cubes to precipitate, vacuum and filter the ice-out solution under reduced pressure, Wash with concentrated hydrochloric acid until the filtrate is free of sulfate ions, and dry to obtain sulfonation-reduced scarlet powder.

[0057] 1 gram of sulfonated reduced scarlet GG and 2 grams of sulfonated reduced blue RSN prepared in Example 2 were added to 450 ml of distilled water, magnetically stirred for 1 hour, filtered, then heated and evaporated to concentrate a solution of 12.5% (mass percentage), Cool to room temperature.

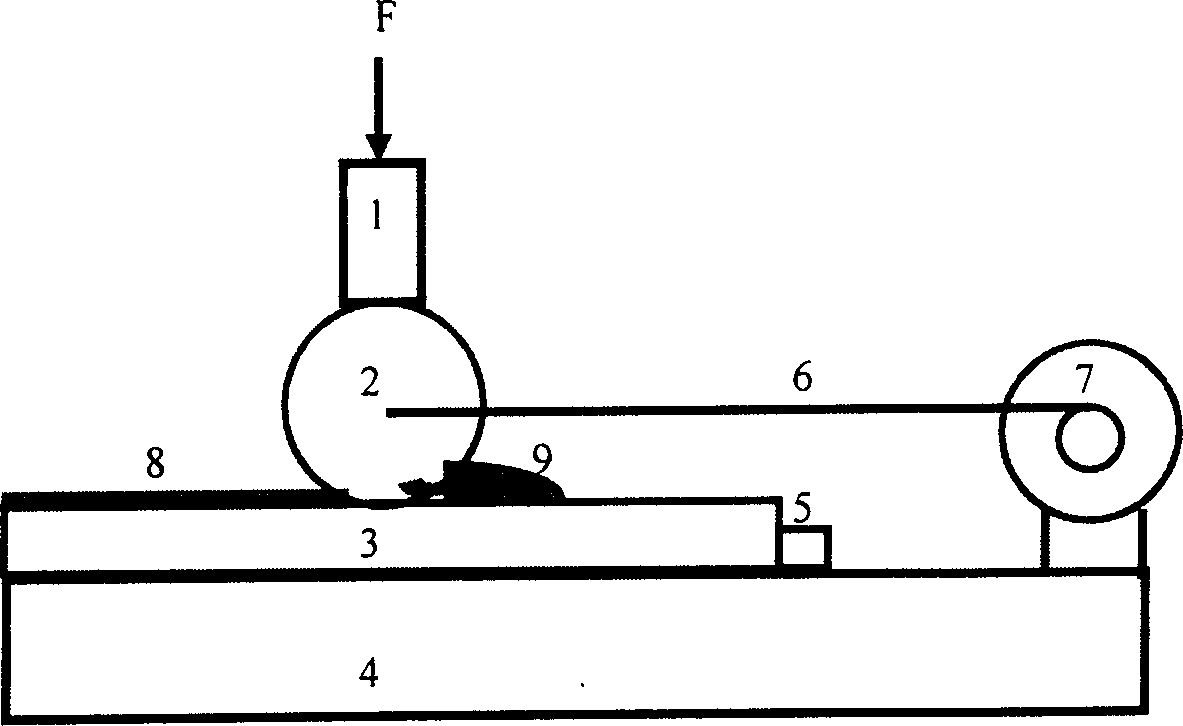

[0058] At a temperature of 25-32°C and a relative humidity of 50-70%, apply the above-mentioned mixed solution with a concentration of 12.5% to a wire rod coater with a winding diameter of 10 microns and a round rod of Φ15mm×150mm to apply shear. The force is 25-30N, and the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com