Heating electrode material for phase transformation memory and preparing method

A phase change memory and heating electrode technology, applied in the field of microelectronics, can solve the problems of stress mismatch and insufficient heating efficiency, and achieve the effects of reducing power consumption, improving heating efficiency and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

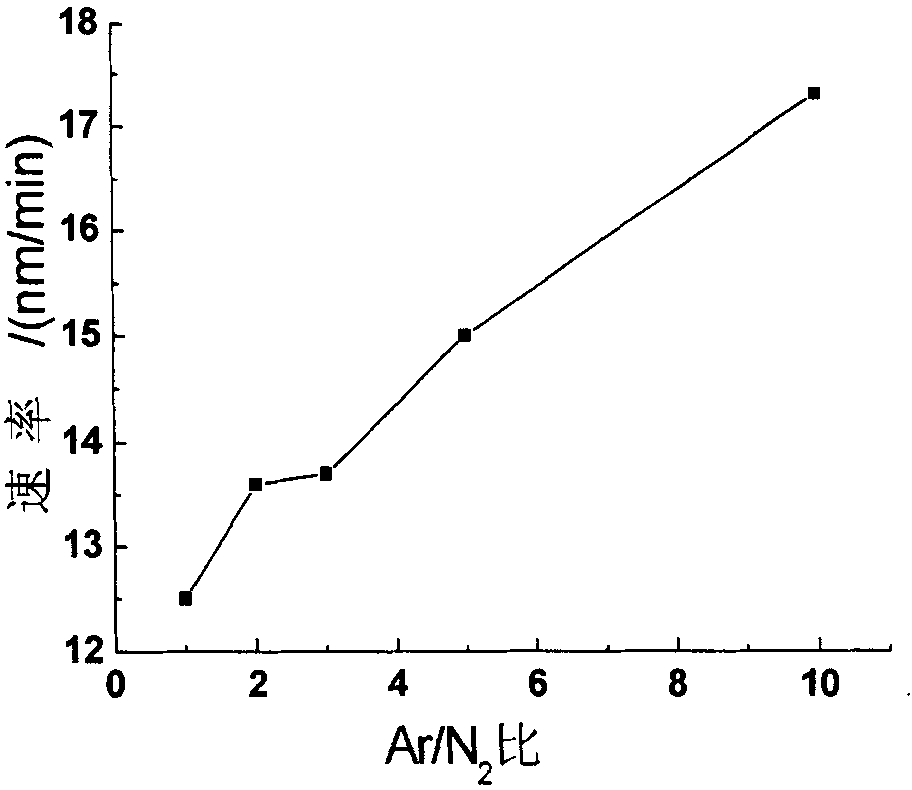

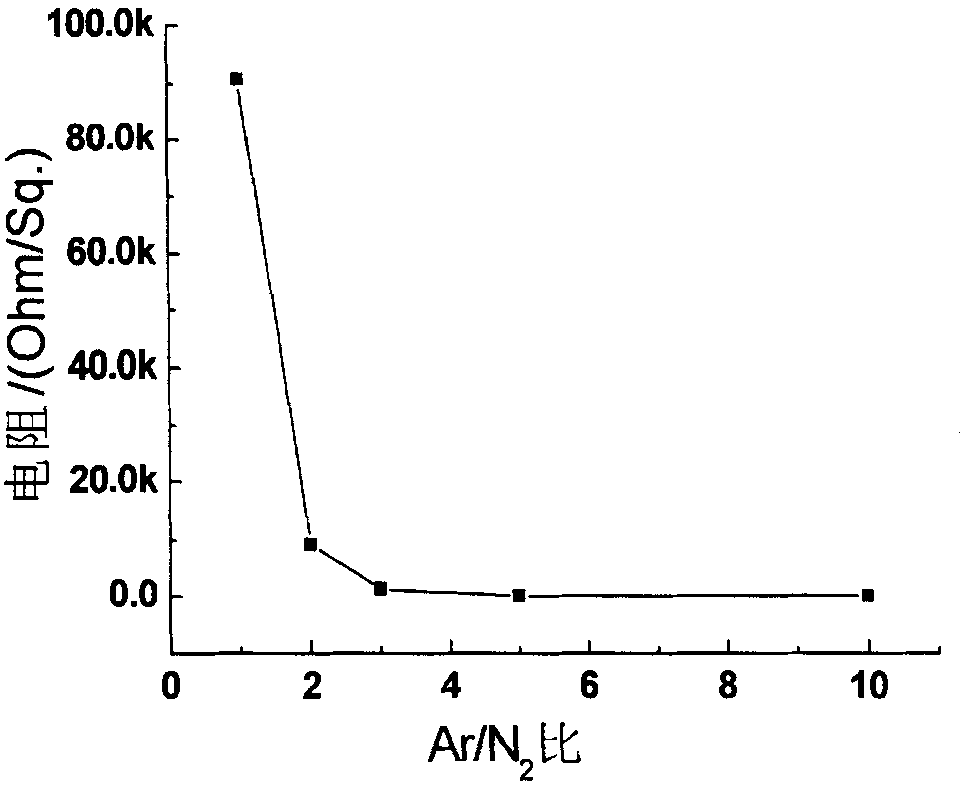

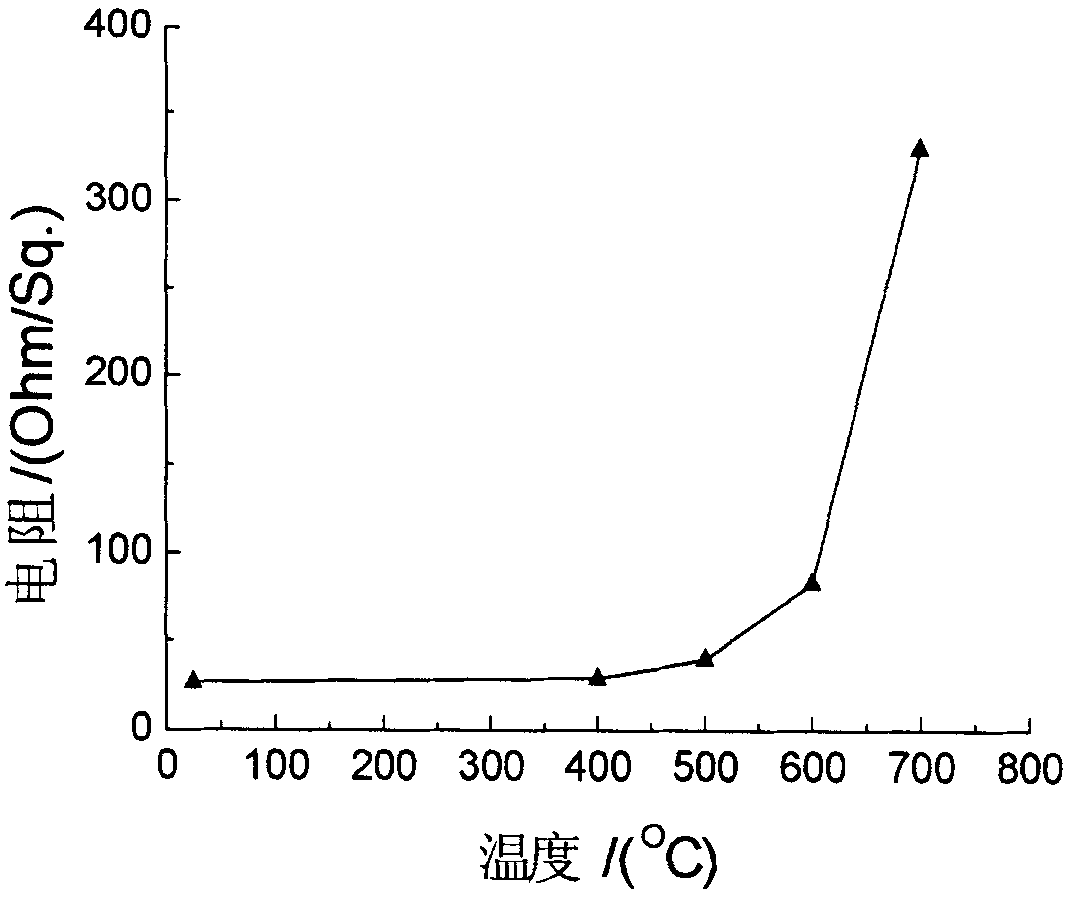

[0021] The Ge-W-N heating electrode material was prepared by double-target magnetron co-sputtering. Prepare two independent pure component Ge targets and W targets, the purity of the targets is greater than 99.99% (atomic percentage), and then adopt the method of double-target magnetron co-sputtering, and simultaneously inject high-purity Ar gas and N 2 Gas, the specific process parameters are as follows: Ge target adopts radio frequency power supply, power is 200W; W target adopts DC power supply, power is 100W; sputtering pressure is 0.2Pa; sputtering time is 10min; 2 The flow ratio can adjust the film preparation rate ( figure 1 ) and sheet resistance ( figure 2 ). by right figure 1 and 2 After analysis, Ar / N 2 When the ratio is 1, the resistance of the thin film is too high, much higher than the resistance of the crystalline phase change material in the phase change memory, and close to the resistance of the amorphous phase change material, which will cause the inab...

Embodiment 2

[0023] The Ge-N heating electrode material was prepared by magnetron sputtering of Ge target. Prepare a Ge target with pure components, the purity of the target is greater than 99.99% (atomic percentage), and then use radio frequency magnetron sputtering to inject high-purity Ar gas and N at the same time during the sputtering process. 2 gas, by changing Ar and N 2 The flow ratio can adjust the composition and preparation rate of the thin film, thereby preparing a series of Ge-N heating electrode materials with different compositions.

Embodiment 3

[0025] The Ge-Ti-N heating electrode material was prepared by double-target magnetron co-sputtering. Prepare two separate Ge targets and Ti targets with pure components, the purity of the targets is greater than 99.99% (atomic percentage), and then use the double-target magnetron co-sputtering method to simultaneously inject high-purity Ar gas and N 2 gas, by changing the sputtering power of Ge target and Ti target and Ar and N 2 The flow ratio can adjust the composition and preparation rate of the thin film, thereby preparing a series of Ge-Ti-N heating electrode materials with different compositions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com