Resin composition for foam and use thereof

A resin composition and foam technology, applied in synthetic resin layered products, applications, layered products, etc., can solve the problems of touch change, hardness reduction, and low foaming ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0191] [Preparation of catalyst solution]

[0192] 18.4 mg of triphenylcarbenium tetrakis(pentafluorophenyl) boron salt was weighed, and 5 ml of toluene was added and dissolved to prepare a toluene solution with a concentration of 0.004 mM / ml. Weigh [dimethyl (tert-butylamide) (tetramethyl-η5-cyclopentadienyl) silane] titanium dichloride 1.8 mg, add 5 ml of toluene and dissolve, and adjust to a toluene concentration of 0.001 mM / ml solution. At the beginning of the polymerization, measure 0.38 ml of toluene solution of triphenylcarbenium tetrakis (pentafluorophenyl) boron salt, [dimethyl (tert-butylamide) (tetramethyl-η5-cyclopentadienyl) Silane] 0.38ml of toluene solution of titanium dichloride, and add 4.24ml of toluene for dilution to prepare triphenylcarbenium tetrakis (pentafluorophenyl) boron salt at 0.002mM / L in B conversion, [dimethyl (tert-butylamide) (tetramethyl-η5-cyclopentadienyl) silane] titanium dichloride 0.0005 mM / L toluene solution 5 ml in conversion of Ti. ...

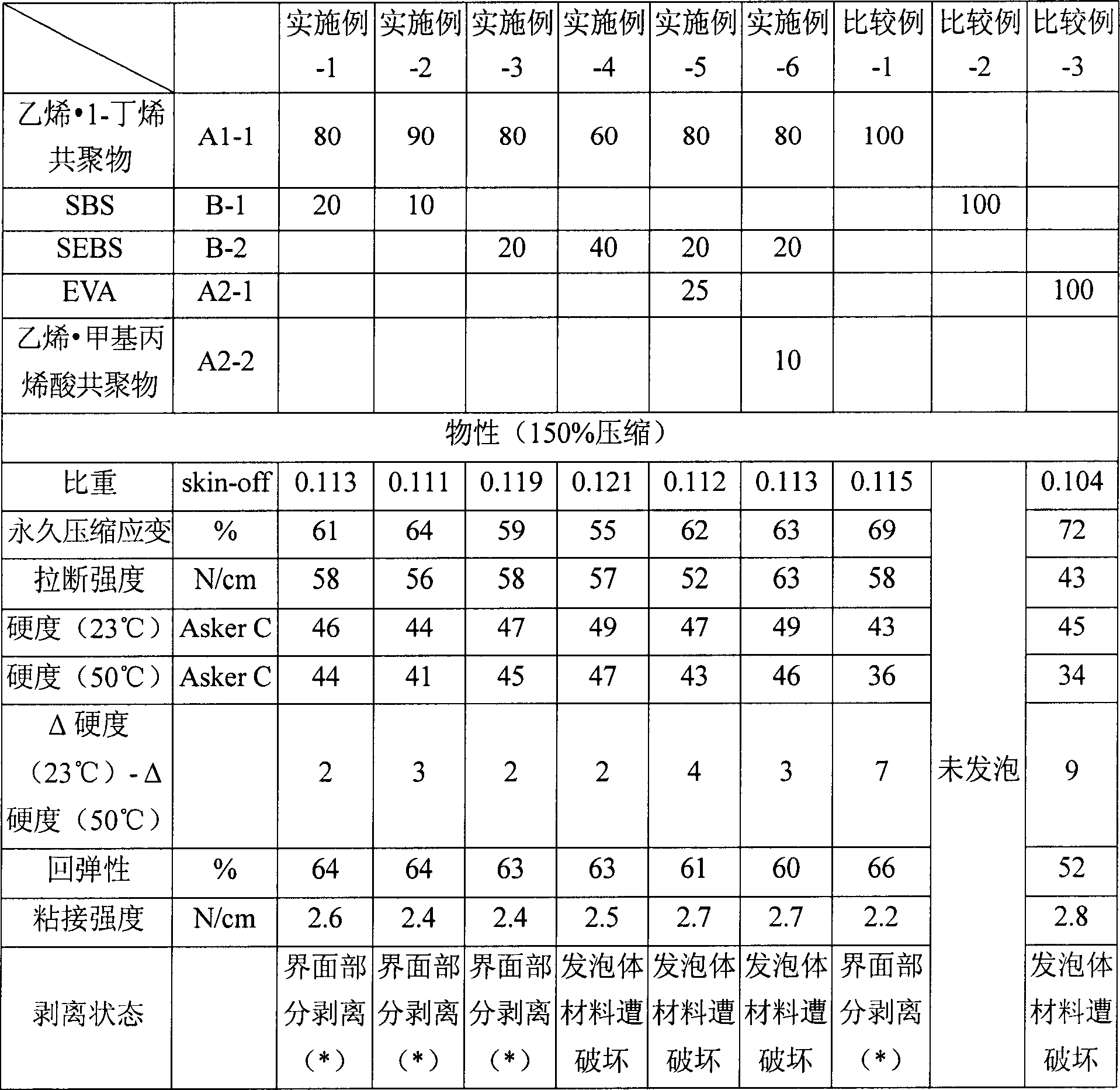

Embodiment 1

[0197] Will be made up of: 80 parts by weight of ethylene·1-butene copolymer (A1-1), 20 parts by weight of styrene·butadiene·styrene block copolymer (SBS) (B-1), 3.0 parts by weight of zinc oxide, 0.6 parts by weight of dicumyl peroxide (DCP), 0.07 parts by weight of triallyl isocyanate (TAIC) [trade name M-60 (TAIC content 60%), manufactured by Nippon Kasei Co., Ltd. (TAIC content) 1, 2-Polybutadiene 0.3 weight part, azodicarbonamide 7 weight parts of the mixture, using a roll, the roll surface temperature is 120 ° C, kneading for 10 minutes, formed into a flake.

[0198] The obtained flakes are filled in a compression mold at 150kg / cm 2 , 155° C., and 30 minutes, pressurized and heated to obtain a primary cross-linked foam. The size of this pressing die is 15 mm in thickness, 150 mm in length, and 200 mm in width.

[0199] Then, this primary cross-linked foam was mixed at 150kg / cm 2 , Under the condition of 155° C., perform compression molding for 10 minutes to obtain a s...

Embodiment 2

[0202] In Example 1, 80 parts by weight of ethylene-1-butene copolymer (A1-1) was changed to 90 parts by weight, and styrene-butadiene-styrene block copolymer (SBS) (B- 1) 20 parts by weight was changed to 10 parts by weight. Except for this, the rest were the same as in Example 1, and a secondary crosslinked foam was prepared, and the physical properties were measured. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com