Composite electro and magneto conductive polyaniline microsphere and its prepn

A technology of conductive polyaniline and composite microspheres, which is applied in the field of functional materials, can solve the problems of difficult film formation of polymer microspheres, easy agglomeration and restriction of microspheres, and achieve good repeatability, uniform and controllable film thickness, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

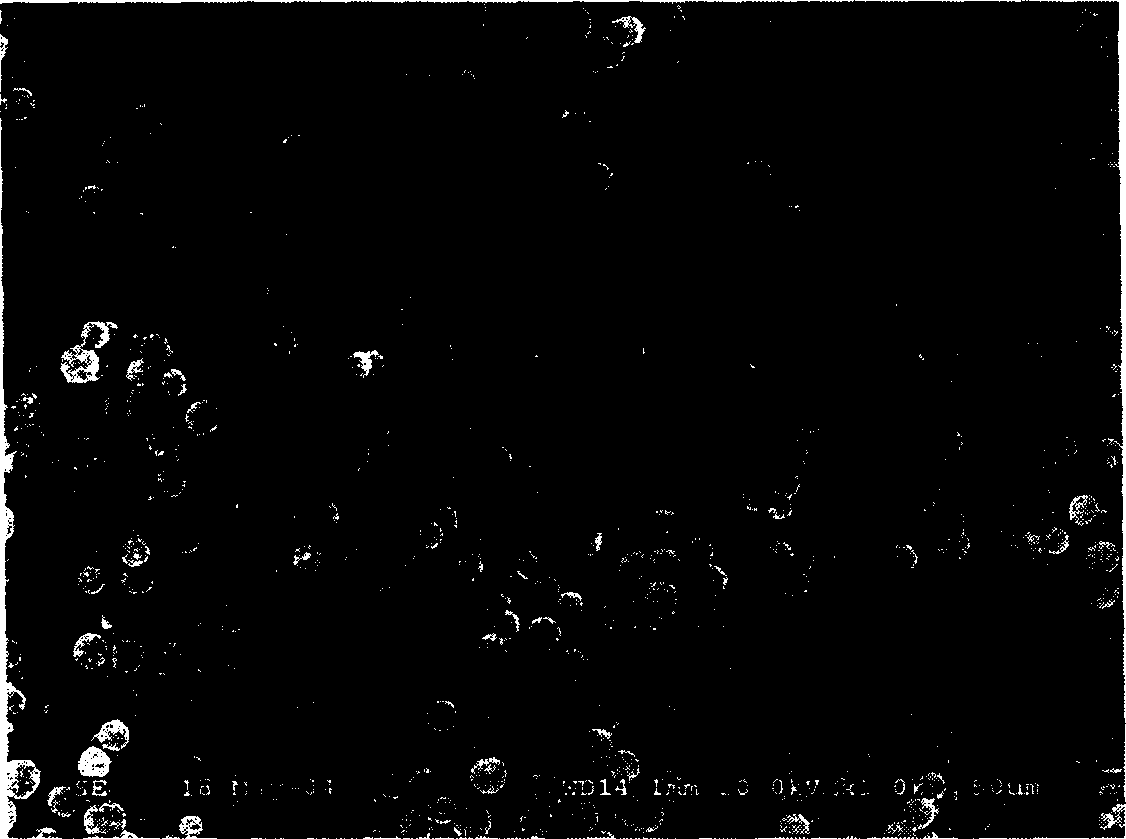

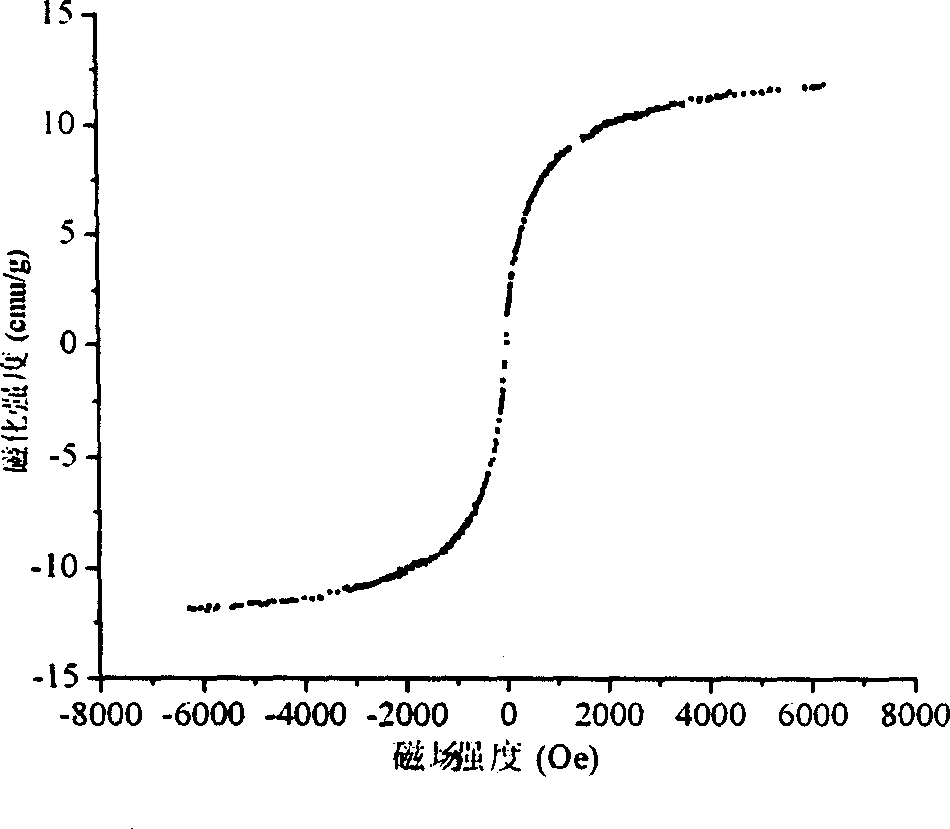

Image

Examples

Embodiment 1

[0031] 1) Dissolve 100mg intrinsic polyaniline in 10ml chloroform, add 128mg dodecylbenzenesulfonic acid, stir the mixed solution ultrasonically for 5h at room temperature; filter to remove the undissolved polyaniline, the filtrate obtained is 12 Conductive polyaniline solution doped with alkylbenzene sulfonic acid;

[0032] 2) Add 150 mg of polyethylene glycol (PEG, weight average molecular weight of 20000) to 3 ml of the conductive polyaniline solution prepared in step 1), and ultrasonically mix;

[0033] 3) Disperse 180 mg of magnetic ferroferric oxide in 6 ml of chloroform, add 0.06 mg of dodecylbenzene sulfonic acid, and mix well to obtain a magnetic dispersion;

[0034] 4) Add the magnetic dispersion liquid in step 3) to the mixed solution prepared in step 2), and ultrasonically mix to obtain a magnetic conductive polyaniline electrospinning solution;

[0035] 5) Pour the magnetic conductive polyaniline electrospinning solution prepared in step 4) into a vertically placed li...

Embodiment 2

[0040] 1) Dissolve 100mg intrinsic polyaniline in 10ml chloroform, add 128mg p-toluenesulfonic acid, stir the mixed solution ultrasonically for 5h at room temperature; filter to remove the undissolved polyaniline, the filtrate obtained is p-toluenesulfonic acid doped Mixed conductive polyaniline solution;

[0041] 2) Add 300 mg of polyethylene glycol (PEG, weight average molecular weight of 20000) to 3 ml of step 1) into 3 ml of the conductive polyaniline solution prepared in step 1), and ultrasonically mix;

[0042] 3) Disperse 90 mg of magnetic ferroferric oxide in 3 ml of chloroform solvent, add 0.03 mg of sodium dodecylbenzene sulfonate, and mix well to obtain a magnetic dispersion;

[0043] 4) Add the magnetic dispersion liquid in step 3) to the mixed solution prepared in step 2), and ultrasonically mix to obtain a magnetic conductive polyaniline electrospinning solution;

[0044] 5) Pour the magnetic conductive polyaniline electrospinning solution prepared in step 4) into a v...

Embodiment 3

[0049] 1) Dissolve 100mg intrinsic polyaniline in 10ml chloroform, add 128mg p-toluenesulfonic acid, stir the mixed solution ultrasonically for 5h at room temperature; filter to remove the undissolved polyaniline, the filtrate obtained is p-toluenesulfonic acid doped Mixed conductive polyaniline solution;

[0050] 2) Add 150 mg of polylactide (PLA, with a weight average molecular weight of 80,000) to 3 ml of the conductive polyaniline solution prepared in step 1), and ultrasonically mix;

[0051] 3) Disperse 90 mg of magnetic ferroferric oxide in 3 ml of chloroform solvent, add 0.03 mg of sodium dodecylbenzene sulfonate, and mix well to obtain a magnetic dispersion;

[0052] 4) Add the magnetic dispersion liquid in step 3) to the mixed solution prepared in step 2), and ultrasonically mix to obtain a magnetic conductive polyaniline electrospinning solution;

[0053] 5) Pour the magnetic conductive polyaniline electrospinning solution prepared in step 4) into a vertically placed liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com