Ultraviolet irradiation apparatus

An irradiation device and ultraviolet technology, which is applied in the direction of lighting devices, measuring devices, nonlinear optics, etc., can solve problems such as inability to reliably detect non-lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

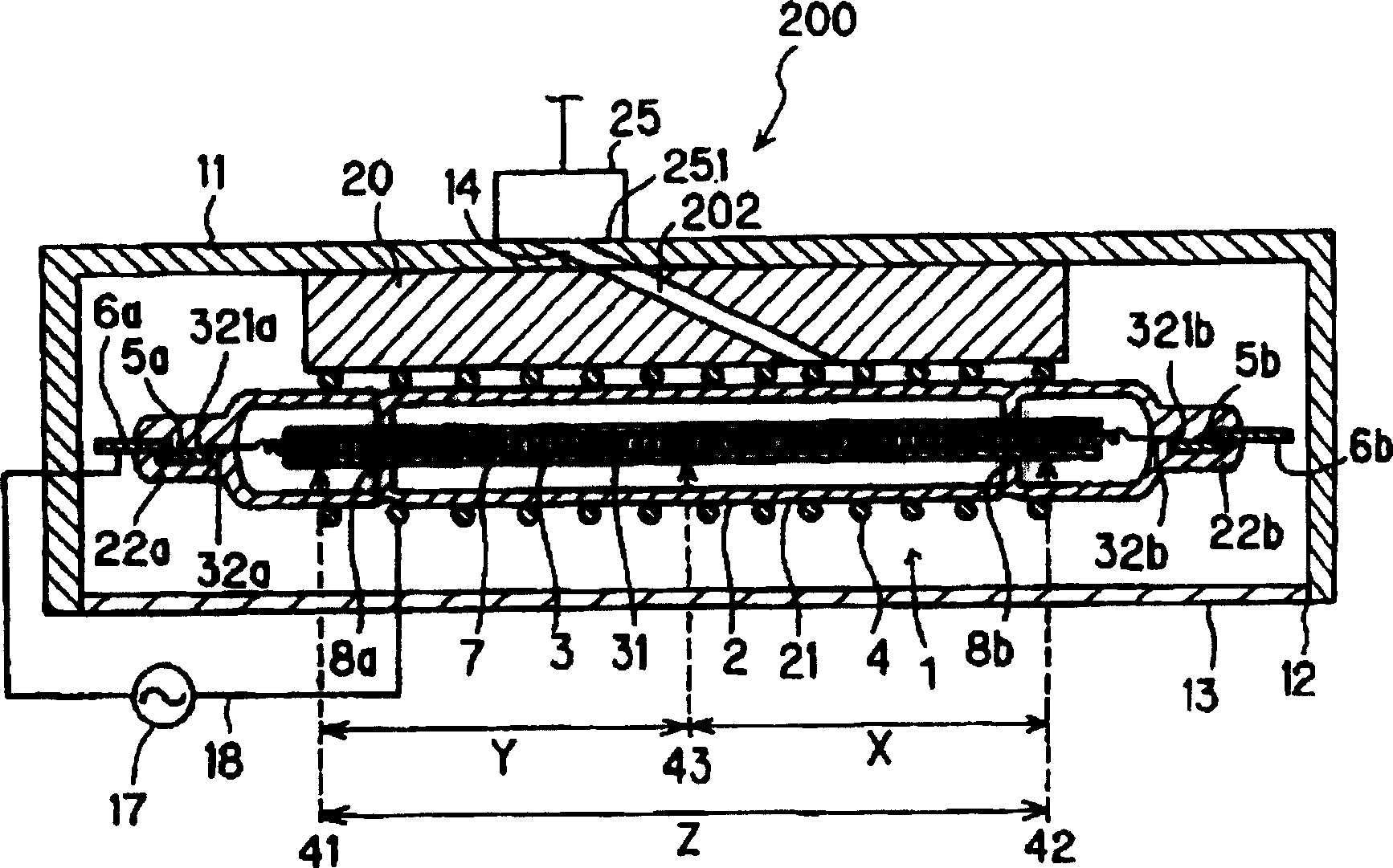

[0041] Fig. 1 is a cross-sectional view showing a first ultraviolet irradiation device of the present invention. FIG. 1( a ) is a cross-sectional view showing the ultraviolet irradiation device taken along a plane perpendicular to the tube axis of the excimer lamp. Fig. 1(b) is a cross-sectional view showing the ultraviolet irradiation device shown in Fig. 1(a) cut along the tube axis direction of the excimer lamp on a plane including the M-M' line.

[0042] The ultraviolet irradiation device 100 accommodates four excimer lamps 1 having a single-layer cylindrical structure in a box-shaped frame 11 and is arranged to face a substrate 36 , which is an object to be processed, placed on a transport mechanism 35 .

[0043] A light extraction window member 13 made of, for example, quartz glass for extracting vacuum ultraviolet light from the excimer lamp to the outside is disposed in the opening 12 of the housing 11 . A through-hole 14 is formed at a position above the excimer lamp...

no. 2 Embodiment approach

[0082] Figure 5 It is a cross-sectional view showing the second ultraviolet irradiation device of the present invention taken along a plane including the tube axis of the excimer lamp. The same symbols as those in Fig. 1 indicate the same or corresponding parts. The ultraviolet irradiation device 500 has the same structure as the ultraviolet irradiation device shown in FIG. 1 except that the excimer lamp 50 having a double-tube structure is used.

[0083] The excimer lamp 50 has a discharge vessel 55 having a double-tube structure. The discharge vessel 55 includes a cylindrical outer tube 51 made of a dielectric such as quartz glass and having an outer diameter smaller than the inner diameter of the outer tube 51. For example, a cylindrical inner tube 52 made of a dielectric such as quartz glass, and side wall portions 53, 54 that airtightly seal the two ends of the cylindrical space formed by the outer tube 51 and the inner tube 52; The cylindrical discharge space S formed...

no. 3 Embodiment approach

[0088] Fig. 6 is a cross-sectional view of the third ultraviolet irradiation device of the present invention taken along a plane including the tube axis of the excimer lamp. The same symbols as in Fig. 1 indicate the same or corresponding parts.

[0089] Both the external lead wires 6 a and 6 b of the ultraviolet irradiation device 600 and the external electrode 4 are connected to the power supply device 17 through the power supply line 18 . The area near the center of the effective light-emitting area Z (the following Figure 7 Corresponding to the area indicated by the V line in the above, the light guide part 202 penetrating the cooling member 20 in the vertical direction is formed correspondingly, and the light receiving part 25 is placed on the on frame 11. The "region near the center" refers to a position where the light receiving unit 25 can observe the center of the excimer lamp. Except for these points, other configurations are the same as those of the ultraviolet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com