High length-diameter ratio antifungin whisker synthesis method

A magnesium borate whisker and synthesis method technology, applied in the field of magnesium borate whisker synthesis, can solve the problems of large-scale industrial implementation difficulty, expensive equipment, environmental pollution, etc., to reduce spray drying process, reduce service life, and avoid gas pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

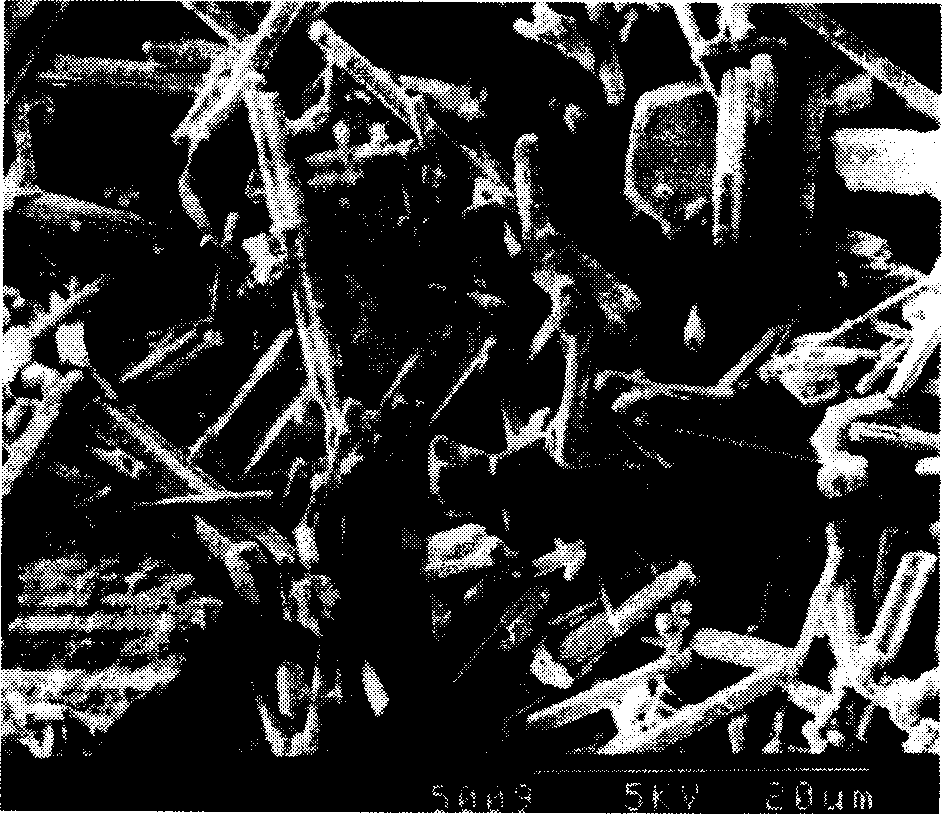

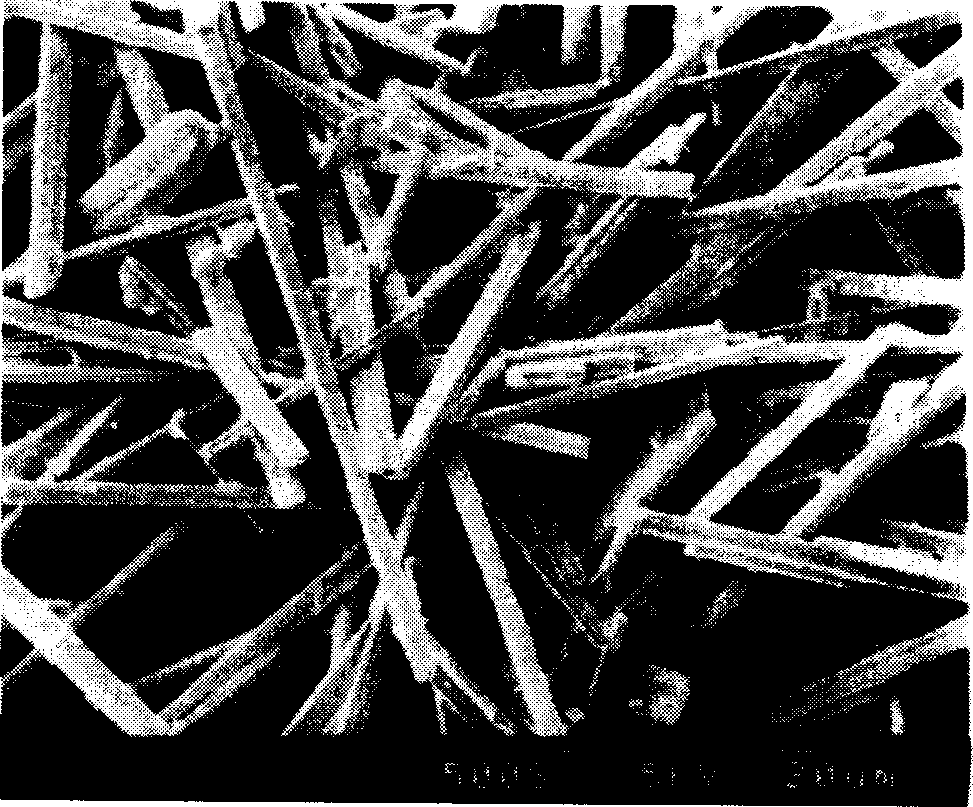

[0028] 233.3 grams of industrial grade MgCl 2 ·6H 2 O and 65 grams of industrial primary boric acid were added to 1560ml of H 2 In O, add 92 grams of NaOH again, stir at 40°C for 50 minutes, let stand and age for 2 hours, filter to obtain 160 grams of magnesium borate whisker precursor, mix the precursor with 32 grams of industrial grade NaCl and 80 grams of Mix industrial grade KCl in solid phase, then add water, the solid-liquid ratio (mass ratio) is 1:0.5, stir evenly at room temperature, filter, put the filtered mixed starting material in a crucible, put it in a high-temperature furnace React at a high temperature of 850°C for 5 hours, take it out after cooling, soak in 200 grams of water, wash, filter, and dry in a drying oven at 80°C for 10 hours to obtain magnesium borate whiskers. The analysis results are shown in Table 1. figure 1 .

Embodiment 2

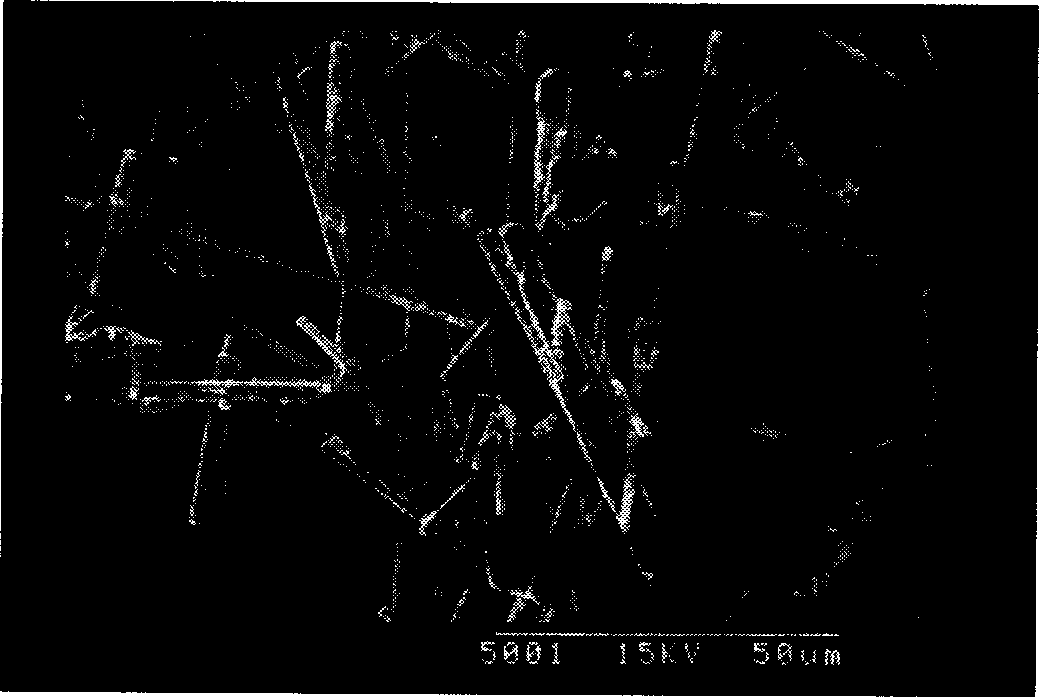

[0030] 169 grams of industrial grade MgCl 2 ·6H 2 O and 65 grams of industrial primary boric acid were added to 400ml of H 2 Add 169 grams of NaOH to O, stir at 40°C for 30 minutes, let stand and age for 1 hour, and filter to obtain 144 grams of magnesium borate whisker precursor, which is mixed with 120 grams of industrial grade NaCl in solid phase , add the organic solvent that is made up of methanol, ethanol, water again, its proportioning is methanol: ethanol: water=4: 3: 3 (mass ratio), mix, solid-liquid ratio (mass ratio) is 1: 3, under normal temperature Stir evenly, filter, put the filtered mixed starting material in a crucible, put it into a high-temperature furnace and react at 900°C for 10 hours, cool, soak in 200g of water, wash, filter, and dry in a drying oven at 100°C for 3 hour, obtain the magnesium borate whisker product. The analysis results are shown in Table 1. figure 2 .

Embodiment 3

[0032] 325 grams of industrial grade MgCl 2 ·6H 2 O and 65 grams of industrial primary boric acid were added to 500ml of H 2 In O, add 65 grams of NaOH again, stir at 40°C for 30 minutes, let stand and age for 1 hour, filter to obtain 130 grams of magnesium borate whisker precursor, and mix the precursor with 65 grams of industrial grade NaCl and 13 grams of Industrial first-grade KCl solid phase mixing, then add organic solvent composed of methanol, ethanol, water, its proportioning ratio is methanol: ethanol water = 4: 3 (mass ratio), mixed, the solid-liquid ratio (mass ratio) is 1: 0.5, stir evenly at room temperature, filter, put the filtered mixed starting material in a crucible, put it in a high-temperature furnace and react at a high temperature of 500°C for 10 hours, cool, soak in 200g of water, wash, filter, and dry at 100°C Dry in the box for 3 hours to obtain the magnesium borate whisker product. The analysis results are shown in Table 1. figure 2 .

[0033] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com