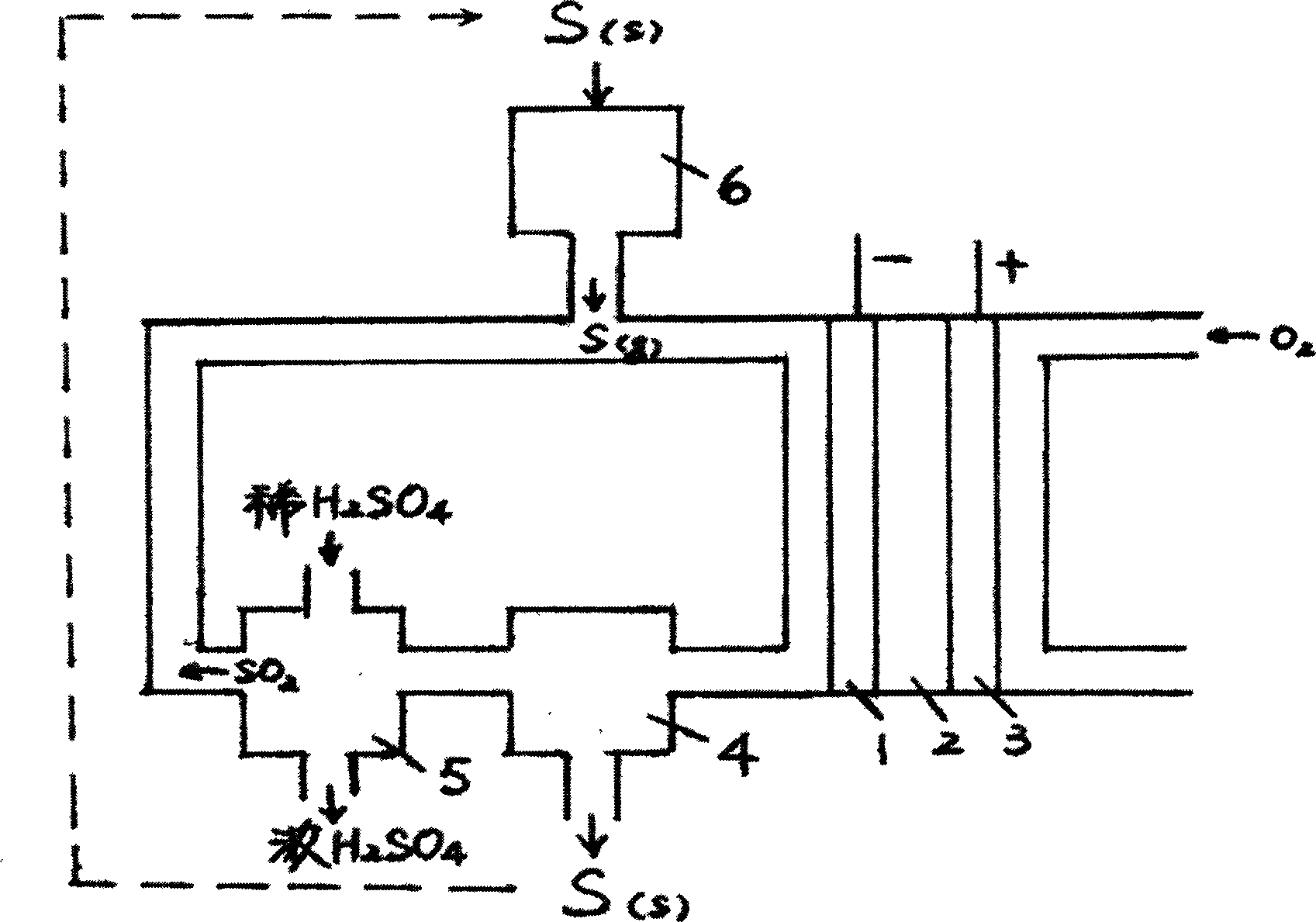

Sulfur-air fuel cell and its application in sulfuric acid production

An air fuel cell, fuel cell technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems of undiscovered sulfur-air fuel cells, etc., and achieve obvious environmental protection effects, reduce production costs, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] As shown in the accompanying drawing of the manual, it is equipped with a sulfur-air fuel cell, and the positive electrode of the battery is YMnO mixed with 20% silver powder. 3 The material is composed of pressed tablets, and the solid electrolyte is made of perovskite structure La 0.8 Sr 0.2 GaO 2.9 Material composition, the negative electrode of the battery is doped with 45% LaCrO 3 YSZ (yttria stabilized zirconia) material pellets. Battery negative lead into S (g) , the partial pressure is 110kPa, the flow rate is 10cm 3 / min; the positive electrode of the battery is fed with air, the pressure is 100kPa, the oxygen partial pressure is 21kPa, and the air flow rate is 500cm 3 / min; the working temperature of the battery is 500°C. The battery output voltage is 0.9V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com