New preparation method of positive and negative electrode materials of lithium ion secondary cell by spraying thermal decomposition

A secondary battery, spray pyrolysis technology, applied in the direction of battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of particle size, shape specific surface area and tap density that are difficult to meet the requirements, complex process routes, cumbersome processes, etc. , to achieve the effect of avoiding roasting process, low energy consumption and continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

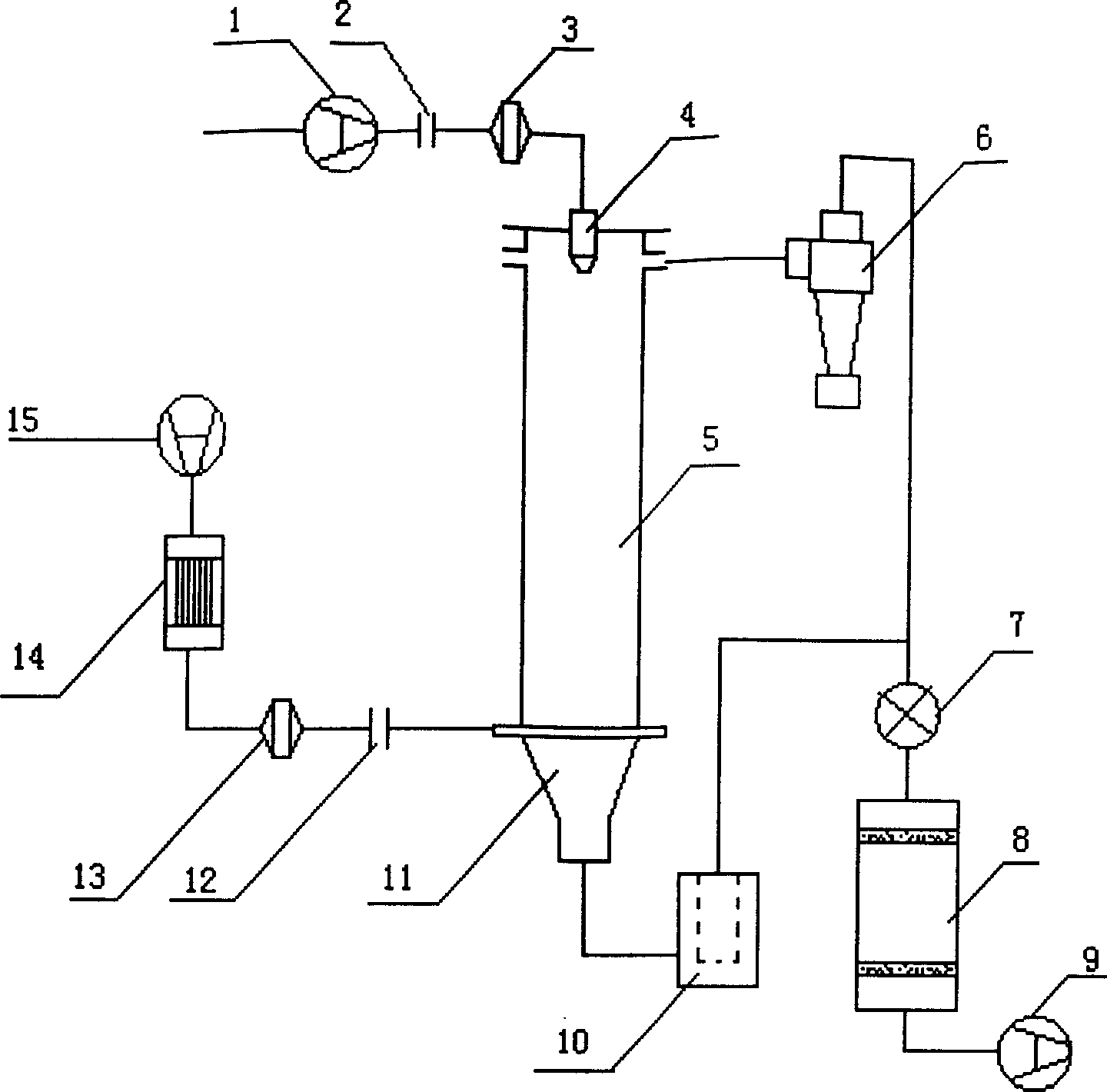

[0021] The preparation process of the present invention is as follows:

[0022] 1. Precursor configuration

[0023] Weigh lithium salt or tin salt or manganese salt or titanium salt and one or more metal salts mentioned above according to the stoichiometric ratio and weigh the raw materials required to prepare the product, and mix and dissolve them in deionized water or organic solvent , dubbed 0.05-1.5mol / l precursor solution. The organic solvent is any one of acetic acid, ethanol, and maleic acid.

[0024] 2. Precursor atomization

[0025] The mixed multi-component solution is atomized through the atomization system, the atomization volume is 20-200ml / min, and the medium gas atomization pressure is 0.5-10MPa. Driven by the hydraulic pump, the precursor liquid enters the nozzle and is atomized into fine droplets under the impact of high-speed airflow. The particle size of the droplets after atomization is 5-100μm.

Embodiment 1

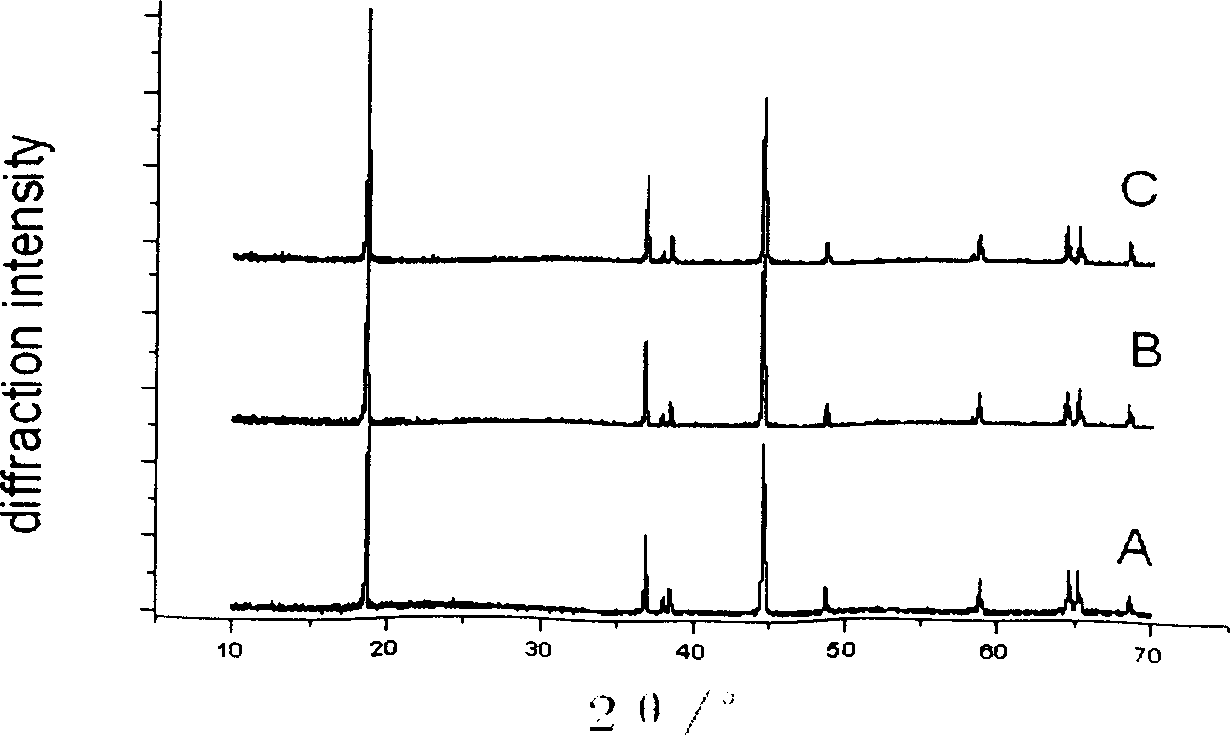

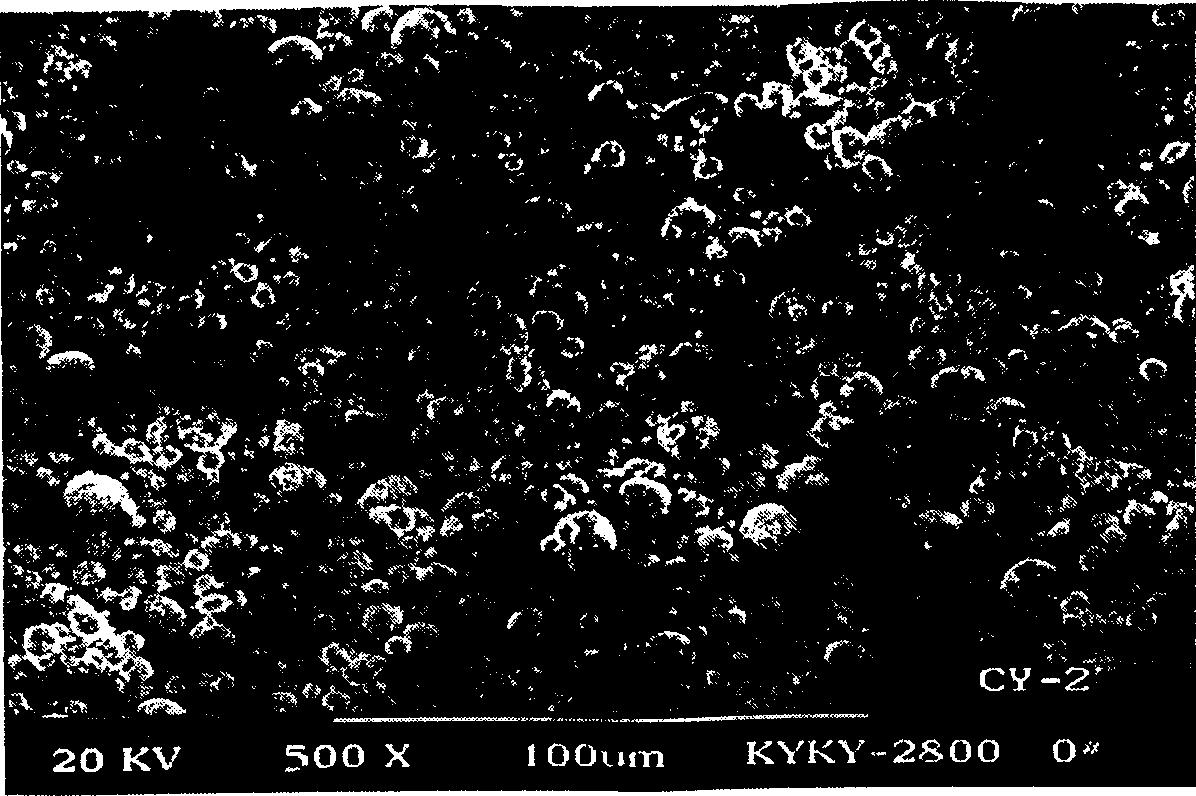

[0031] Weigh LiCl·6H with a molar ratio of Li:Ni:Co:Mn of 3:1:1:1 2 O, NiCl 2 ·6H 2 O, CoCl 2 ·6H 2 O, MnCl 2 4H 2 O, add deionized water to form a precursor solution of 0.2-0.5mol / l, and use a hydraulic pump to feed at a rate of 40-150ml / min, and control the pressure of the atomizing air in the nozzle to atomize under 1-3MP. Drops pass through the pyrolysis reactor to complete drying, pyrolysis, and sintering in an instant to directly obtain spherical or quasi-spherical LiNi with excellent crystal quality and high vibration density. 1 / 3 co 1 / 3 mn 1 / 3 o 2 , the button battery made of this material has a detection specific capacity of 184mAh / g, and the charge-discharge efficiency is still greater than 98.5% after 100 charge-discharge cycles.

Embodiment 2

[0033] Weigh SnCl and TiCl with the Sn:Ti molar ratio of 1:1 2 , adding deionized water to make a precursor solution of 0.1-1.5mol / 1, through the hydraulic pump with a feed rate of 20-150ml / min, the pressure of the atomizing air of the nozzle is controlled at 1-3MP to atomize, and the droplets Through the pyrolysis reaction furnace, the drying, pyrolysis and sintering are completed in an instant, and the spherical or quasi-spherical SnTiO with excellent crystal quality and large vibration ratio can be obtained directly. 2 , The material is made into a button battery with a detected specific capacity of 380mAh / g, and the charge-discharge efficiency is still greater than 95% after 100 charge-discharge cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com