Hydrotreatment catalyst and its preparing method

A hydroprocessing and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low activity of loaded hydroprocessing catalysts, and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

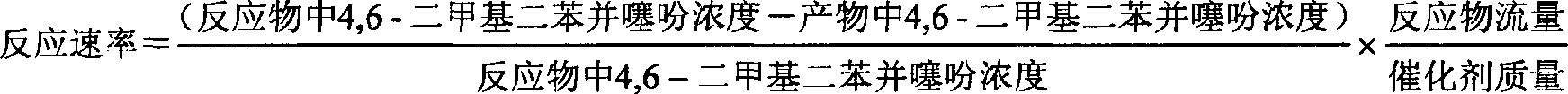

Method used

Image

Examples

Embodiment 1

[0027] The method provided by the invention and the catalyst prepared by the method are illustrated.

[0028] Dissolve 666 grams of aluminum sulfate with deionized water into a solution a1 with a molar concentration of 0.5, and dissolve 800 grams of ammonium bicarbonate with deionized water into a solution b1 with a molar concentration of 2.5. At room temperature, solution a1 and solution b1 were simultaneously added to a 10-liter gelation tank for reaction in a co-current manner. During the reaction, the pH value was controlled to be 6.5, and the temperature was raised to 55°C and sank at this temperature for 1.5 hours, and then filtered. The filter cake was washed three times with 10 times (by weight) deionized water at 55° C., and filtered to obtain filter cake c1.

[0029]26.5 grams of ammonium bicarbonate was dissolved with 350 grams of deionized water to form solution d1, and 97.5 grams of nickel nitrate was dissolved with 350 grams of deionized water to form solution e1...

Embodiment 2

[0032] The method provided by the invention and the catalyst prepared by the method are illustrated.

[0033] Get 135 grams of SB powder (product of Condea, Germany, dry basis 74%), add 4 liters of deionized water for beating. 22.1 grams of ammonium bicarbonate was dissolved in 350 grams of deionized water to form solution d2, and 117 grams of nickel nitrate was dissolved in 350 grams of deionized water to form solution e2. Under stirring, d2 and e2 solutions were added to the above-mentioned alumina hydrate slurry concurrently, the temperature was raised to 60° C., and sedimentation was carried out for 2 hours. Filter to obtain filter cake f2. Wherein the molar ratio of carbonate to group VIII metal component is 1.45.

[0034] Dissolve 16.5 grams of ammonium molybdate and 29.4 grams of ammonium metatungstate in 500 grams of deionized water to form solution h2. Add 3 liters of deionized water to the filter cake f2 obtained above to make a slurry, heat it to 95°C, then add t...

Embodiment 3

[0036] The method provided by the invention and the catalyst prepared by the method are illustrated.

[0037] Get 137 grams of CD powder (Changling Refinery Catalyst Factory product, dry basis 73%), add 4 liters of deionized water for beating. 31.8 grams of ammonium bicarbonate was dissolved in 350 grams of deionized water to form solution d3, and 81.3 grams of nickel nitrate was dissolved in 350 grams of deionized water to form solution e3. Under stirring, d3 and e3 solutions were added to the above-mentioned alumina hydrate slurry concurrently, the temperature was raised to 75°C, and sedimentation was carried out for 1 hour. Filter to obtain filter cake f3. Wherein the molar ratio of carbonate to group VIII metal component is 0.7.

[0038] Dissolve 23.8 grams of ammonium molybdate and 20.4 grams of ammonium metatungstate in 500 grams of deionized water to form solution h3. Add 3 liters of deionized water to the filter cake f3 obtained above to make a slurry, heat it to 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com