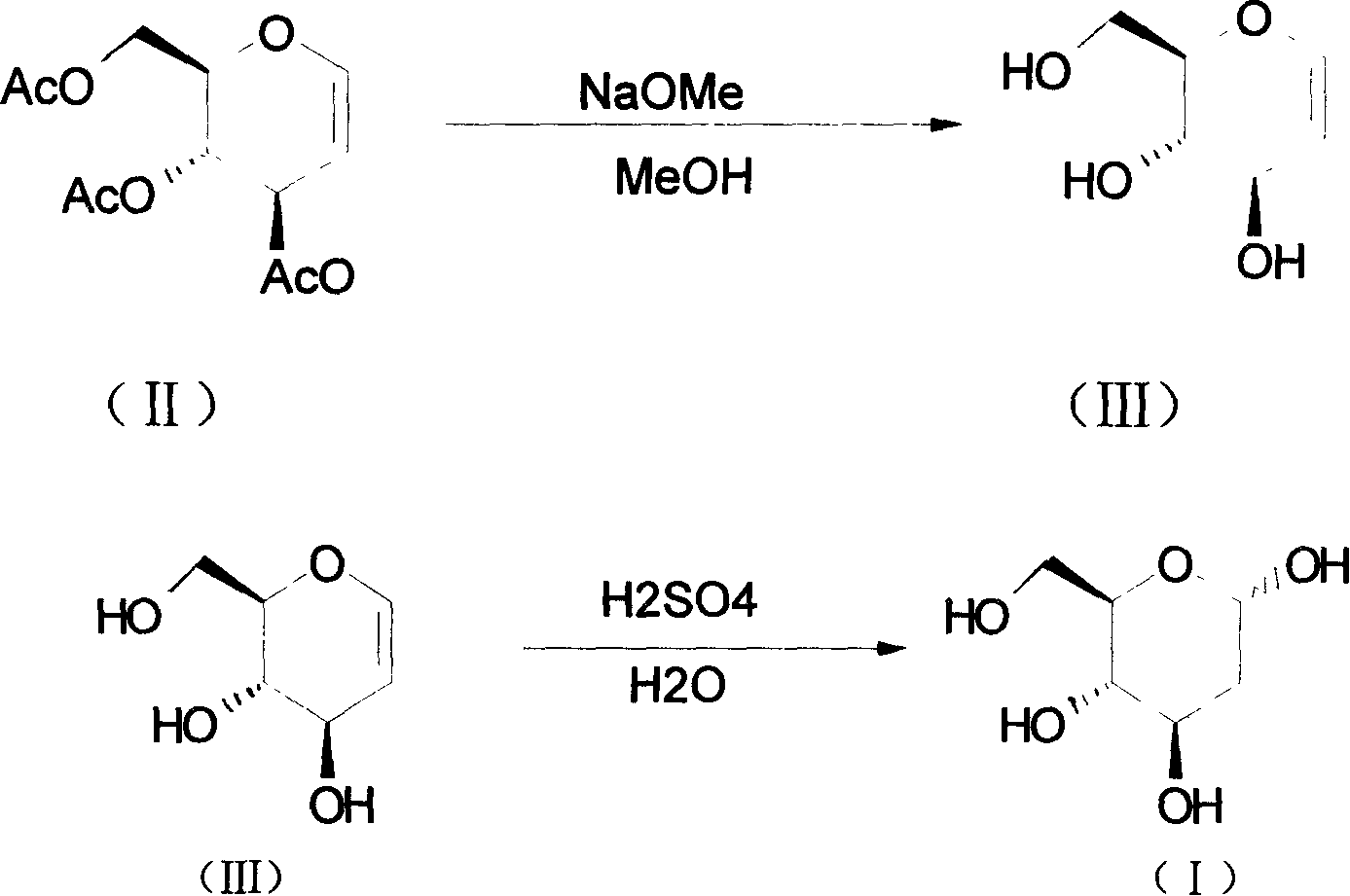

2-deoxidized glucose preparation method

A technology of glucose and glucal sugar, applied in the field of preparation of 2-deoxyglucose, which can solve the problems of high cost, cumbersome reaction process, high toxicity, etc., and achieve the effect of reducing production cost and improving product quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further understand characteristics and effects of the present invention in conjunction with the following examples:

[0023] Add 60kg of D-acetylated glucal sugar and 400L of anhydrous methanol to a 500L reactor, stir to dissolve, slowly add 400g of sodium metal, the pH of the reaction solution is about 10, and control the reaction temperature at 25°C for 12 hours. At the end of the heat preservation, turn on the vacuum pump to distill under reduced pressure, add 400kg of water and 10kg of concentrated sulfuric acid to another 500L reactor, stir the cold brine to cool down, and lower the temperature to 0°C, and the distillation in the 500L reactor is completed to obtain D-glucal. Vacuum pump the material in the 500L reaction kettle into the 500L reaction kettle with sulfuric acid water, stir and keep it warm for 12 hours, control the temperature between -2 and 5°C and finish the heat preservation, add sodium hydroxide for neutralization, and adjust the pH value to about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com