Back washing shell and tube type heat exchanger with sliding cleanliness unit built in

A technology of shell-and-tube heat exchangers and shell-and-tube heat exchangers, which is applied in the field of backwashing shell-and-tube heat exchangers with built-in sliding cleaners, and can solve the problems of increasing equipment investment, increasing system and equipment resistance, and increasing energy consumption of water pumps and other problems, to achieve the effect of convenient control and adjustment and increase of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

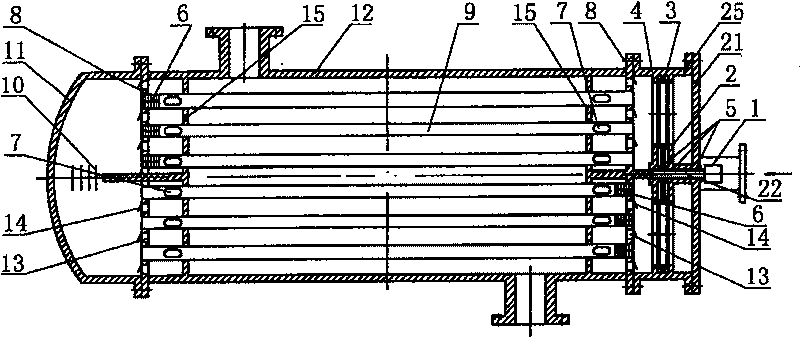

[0036] Built-in sliding cleaner backwash shell and tube heat exchanger, its composition includes: shell and tube heat exchanger, one end of the shell and tube heat exchanger is equipped with a backwash head 25, and the backwash head 25 includes Stepper motor 1, the rotary valve plate 3 installed on the linkage shaft 15 of the stepper motor 1, the rotary valve plate 3 is installed in the right valve plate 2 and the left valve plate in the backwash head 4 middle. The right valve plate 2 is connected to the right head 21, the left valve plate 4 is connected to the right end plate 8, the right end plate 8 is connected to the housing 12, and the other end of the housing 12 is connected to the left end plate 8 connected, the left end plate 8 is connected with the left head 11, the left and right end plates 8 are equipped with heat exchange tubes 9, and the heat exchange tubes 9 are installed in the heat exchange tube bracket 15 at the same time. The heat exchange tube support 15 is...

Embodiment 2

[0038] In the above-mentioned built-in sliding cleaner backwashing shell and tube heat exchanger, the two ends of the heat exchange tube 9 have oval water flow holes 7, and the two holes are horizontally symmetrical, and the two ends of the heat exchange tube 9 are installed There is a built-in sliding cleaner 6, the built-in sliding cleaner 6 is equipped with an elastic fiber brush 19, the built-in sliding cleaner 6 has a cleaner scour surface 20, and the cleaner scour surface 20 has a diameter of Greater than the height of the elliptical water flow holes at both ends of the heat exchange tube, the built-in sliding cleaner 6 can only slide in the heat exchange tube.

Embodiment 3

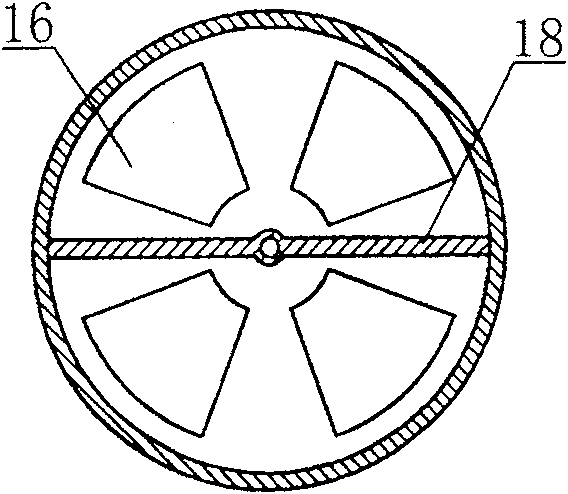

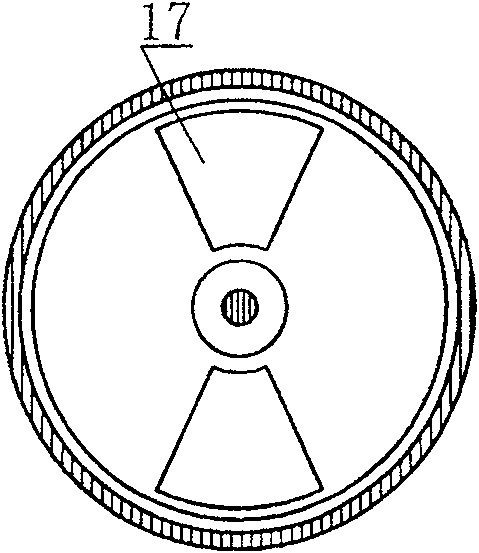

[0040] In the above-mentioned backwashing shell-and-tube heat exchanger with a built-in sliding cleaner, the left valve plate 4 has a transverse partition 18 and a static valve hole 16, and the horizontal partition 18 divides the static valve hole 16 into upper and lower groups. The right valve plate 2 has a longitudinal partition 18 and a static valve hole 16, and the vertical partition 18 divides the static valve hole 16 into two groups, the static valve hole 16 and the right valve hole on the left valve plate 4 Static valve hole 16 on the 2 is facing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com