Process for microwave sintering gyromagnet ferrite material

A gyromagnetic ferrite and microwave sintering technology, which is applied in the field of magnetic material manufacturing equipment, can solve problems such as difficult high-temperature sintering in an oxygen-enriched atmosphere, abnormal growth of material grains, and long sintering cycle, etc. The production efficiency and economic benefits are considerable, and the production cycle is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

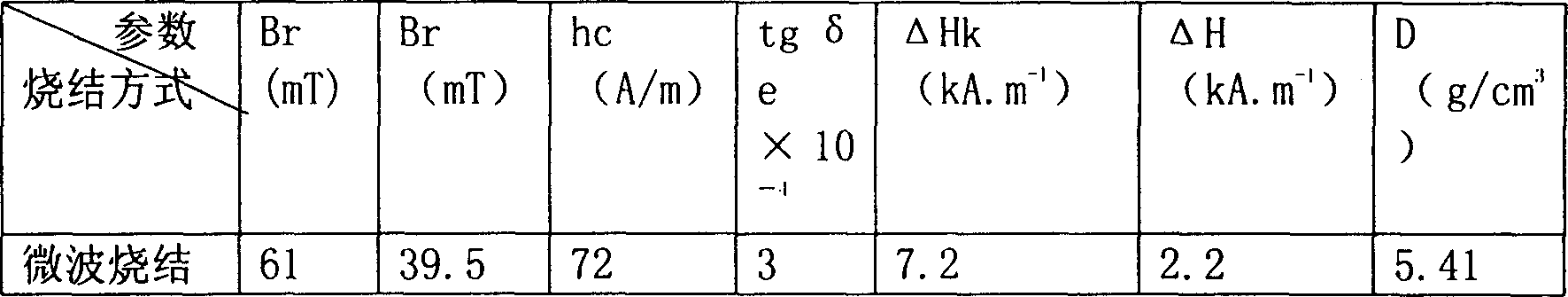

[0006] Embodiment 1, take formula as {Y 3-x Gd x}[Fe 1.8 In 0.2 ](Fe 3-z al z )O 12 500g of the garnet-type gyromagnetic ferrite material is placed in a bell-type microwave oven. The microwave frequency is 2.45GHz, and the furnace is filled with 95% oxygen atmosphere. The heating rate of the material sintering is 8°C per minute, the holding temperature is 1500°C, holding the heat for 40 minutes, and then cooling with the furnace. The entire sintering cycle does not exceed 7 hours, and the energy consumption does not exceed 15kW.h. The test results show that the average grain size of the material is lower than 4 μm, and other performance parameters are shown in Table 1.

[0007] Table 1 Dielectric loss characteristic table

[0008]

Embodiment 2

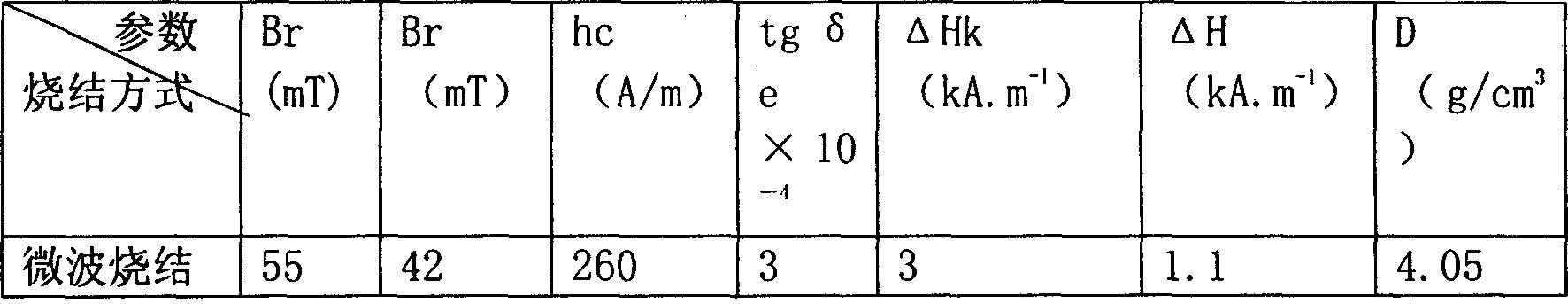

[0009] Embodiment 2, get formula and be LiFe 1 / 2(1-x+y) Mg x TiAl z Fe (2-2y-z) o 4 800g of the gyromagnetic ferrite material is placed in a bell-type microwave oven, the microwave frequency is 2.45GHz, the oxygen atmosphere is 99.5%, the heating rate is 10°C / min, the temperature is 950°C, and the temperature is kept for 40 minutes. The cooling is controlled and the cooling rate is 5°C. / min, sintering cycle ≤ 6 hours, energy consumption ≤ 11kW.h. The test results show that the average grain size of the material is less than 3 μm, and other performance parameters are shown in Table 2.

[0010] Table 2 Dielectric loss characteristic table

[0011]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com