Plasma processing cavity, gas spraying head and manufacturing method thereof

A gas shower head and plasma technology, which is used in the manufacture of semiconductor/solid-state devices, electrical components, discharge tubes, etc., can solve the problems of gas shower head cracking, etc., and achieves low manufacturing cost, dense corrosion-resistant layer and stable structure. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0028] It should be pointed out that the words "semiconductor process piece", "wafer" and "substrate" will often be used interchangeably in the following description, and in the present invention, they all refer to the process processed in the processing chamber. The process parts are not limited to wafers, substrates, substrates, large-area flat substrates, etc. For the convenience of description, the "substrate" will be used as an example in the description and illustrations of the embodiments herein.

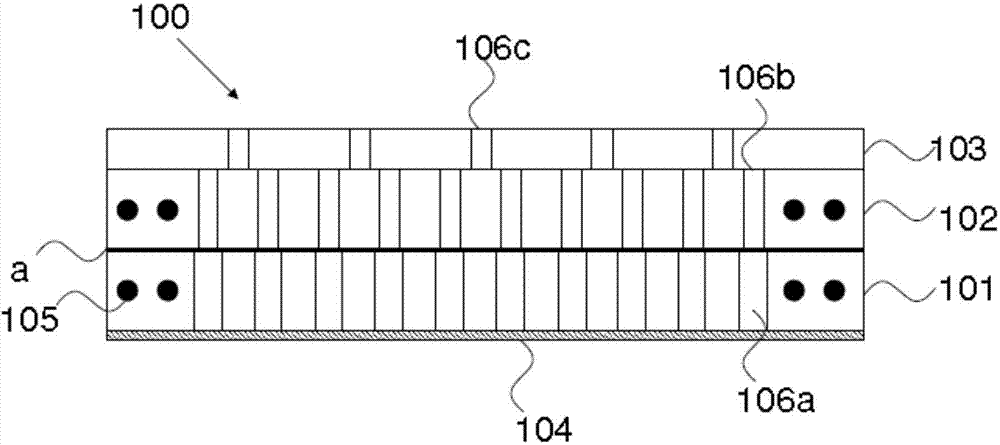

[0029] figure 1 It is a structural schematic diagram of a gas shower head of a plasma processing chamber in the prior art. Such as figure 1 As shown, the showerhead 100 includes a mounting substrate 103 , a second body 102 , a first body 101 , and an yttrium oxide coating 104 from top to bottom. Wherein, the first main body 101 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com