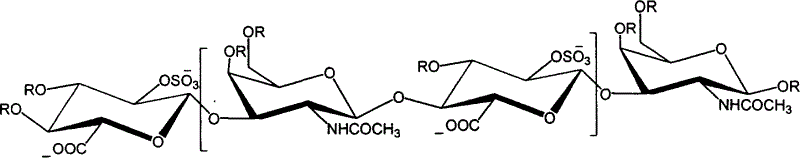

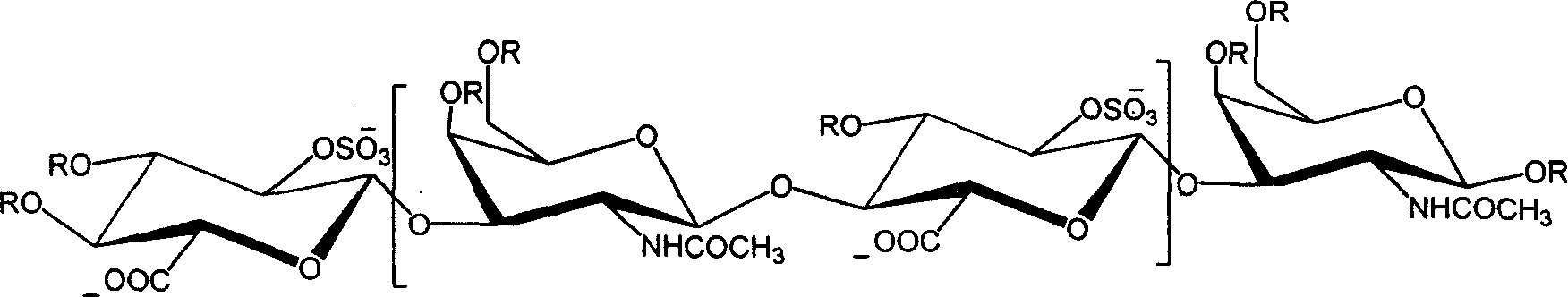

Poly-sulfated chondroitin sulfate and preparation method thereof

A chondroitin sulfate and sulfation technology, which is applied in the field of biomedicine, can solve the problems of different structures and activities of products, unfavorable industrial production, and high cost of reagents, so as to inhibit mast cell degranulation, production environment and equipment requirements are not harsh, reagents low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Polysulfation of chondroitin sulfate: 100 g of chondroitin sulfate boutique (commercially available) is made into a solution with a mass percent concentration of 20%, and chlorosulfonic acid: concentrated sulfuric acid is 1: 0.05 mixed acid is added in the above solution , so that the final concentration of chondroitin sulfate mass percent is 10%, at a temperature of 35° C., stirring and reacting for 5 hours, then adding 4000 ml of absolute ethanol to terminate the reaction, and there will be more sulfated chondroitin sulfate precipitates;

[0024] (2) Separation of the required polysulfated chondroitin sulfate fragments: Dissolve the above precipitate with 1000ml distilled water to make an aqueous solution, adjust the pH to 7 with 20% sodium hydroxide, add 4 times the amount of 95% ethanol to make it Precipitation; then make the precipitate into a 10% aqueous solution, adjust the pH to 10 with 20% sodium hydroxide, heat to 85°C, and continuously perform gas exchange...

Embodiment 2

[0030] (1) Polysulfation of chondroitin sulfate: 200 g of chondroitin sulfate boutique (commercially available) is made into a solution with a mass percentage concentration of 30%, and chlorosulfonic acid: concentrated sulfuric acid is 1: 0.07 mixed acid is added in the above solution , so that the final concentration of chondroitin sulfate mass percent is 10%, at a temperature of 40 ° C, stirring and reacting for 6 hours, then adding 4000ml of absolute ethanol to terminate the reaction, and more sulfated chondroitin sulfate precipitates;

[0031] (2) Separation of the required polysulfated chondroitin sulfate fragments: Dissolve the above precipitate with 1000ml distilled water to make an aqueous solution, adjust the pH to 7 with 20% sodium hydroxide, and add 5 times the amount of 95% methanol to make it Precipitation; then make the precipitate into a 10% aqueous solution, adjust the pH to 10 with 20% sodium hydroxide, heat to 85°C, and continuously perform gas exchange in the...

Embodiment 3

[0034] (1) Polysulfation of chondroitin sulfate: 100 g of chondroitin sulfate boutique (commercially available) is made into a solution with a mass percentage concentration of 25%, and chlorosulfonic acid: concentrated sulfuric acid is 1: 0.09 mixed acid is added in the above solution , making the final concentration of chondroitin sulfate mass percent 10%, at a temperature of 30° C., stirring and reacting for 10 hours, then adding 4000 ml of acetone to terminate the reaction, resulting in more sulfated chondroitin sulfate precipitates;

[0035] (2) Separation of the required polysulfated chondroitin sulfate fragments: dissolve the above precipitate with 1000ml of distilled water to make an aqueous solution, adjust the pH to 7 with 20% sodium hydroxide, add 4 times the amount of acetone to make it precipitate; Then make the precipitate into 10% aqueous solution, adjust the pH to 10 with 20% sodium hydroxide, heat to 85°C, and continuously carry out gas exchange in the reactor, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com