Apparatus for extracting coarse 1,3-butadiene by double baffle plated tower and method thereof

A technology of butadiene and partition tower, which is applied in the field of crude oil extraction, and can solve the problems of numerous equipment, complicated operation, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

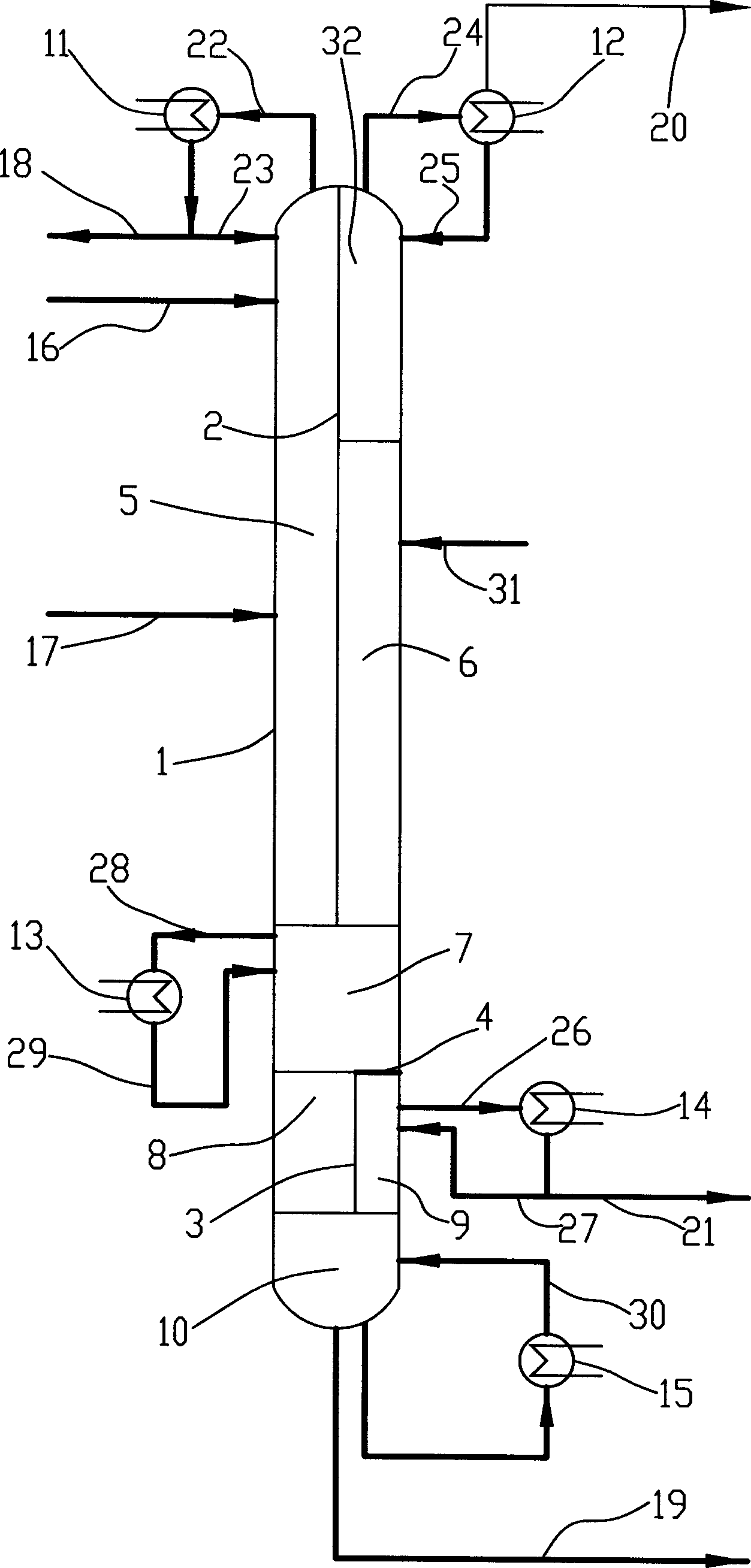

[0021] The internal structure of the partition tower 1 of the device of the present invention is divided into a butadiene extraction and rectification section 5, a weight removal subsection 32, an alkyne extraction and rectification section 6, a common middle tower area 7, a solvent analysis section 8, and an alkyne distillation section 9 and share the lower tower area 10; the butadiene extractive rectification section 5 and the weight-removing fractional section 32, and the alkyne extractive rectification section 6 are separated by the vertical partition plate 2 of the upper section; the solvent analysis section 8 and the alkyne distillation section 9 are used The longitudinal partitions 3 of the lower section are spaced apart, and the alkyne distillation section 9 is separated from the upper common middle tower area 7 by the upper end cover plate 4; a raffinate condenser 11 is provided at the top of the butadiene extraction and rectification section 5; A crude butadiene conde...

Embodiment 2

[0040] The product does not consider the weight-removal component, and the side line tower 33 and related accessories are removed from the partition tower structure. figure 2 Flow process, all the other are identical with embodiment 1.

[0041] Add the 13498.4kg / h C4 mixture stream 17 with a temperature of 54.0°C in gaseous form to the 36th theoretical plate of the butadiene extractive rectification section 5 of the partition column with 100 theoretical plates in total, the aqueous acetonitrile solvent Stream 16 is added to the 4th theoretical plate, and water-containing acetonitrile solvent and carbon four mixture weight ratio are 5.4: 1.0, and carbon four mixture has the weight percent of following composition:

[0042] Propane 0.5047

[0043] Propylene 0.1019

[0044] n-Butane 1.3094

[0045] Isobutane 0.3802

[0046] Isobutylene 23.3535

[0047] 1-butene 16.6869

[0048] trans-2-butene 5.1783

[0049] Cis-2-butene 3.8939

[0050] 1,3-Butadiene 47.5445

[0051] 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com