Method for mounting an electronic component on a substrate

A technology of electronic devices and assembly methods, which is applied in the direction of assembling printed circuits with electrical components, electrical solid devices, printed circuits connected with non-printed electrical components, etc., and can solve problems such as fracture, rupture, and strain of connecting parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

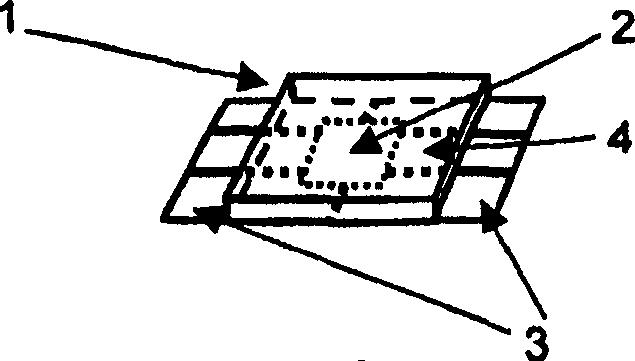

[0029] form a transponder in the figure 1 The device (1) in comprises a chip (2) protected by an insulating material such as an epoxy coating (4). The chip contacts are connected to contact areas (3) formed eg inside a tinned copper conductive plate forming a "lead frame".

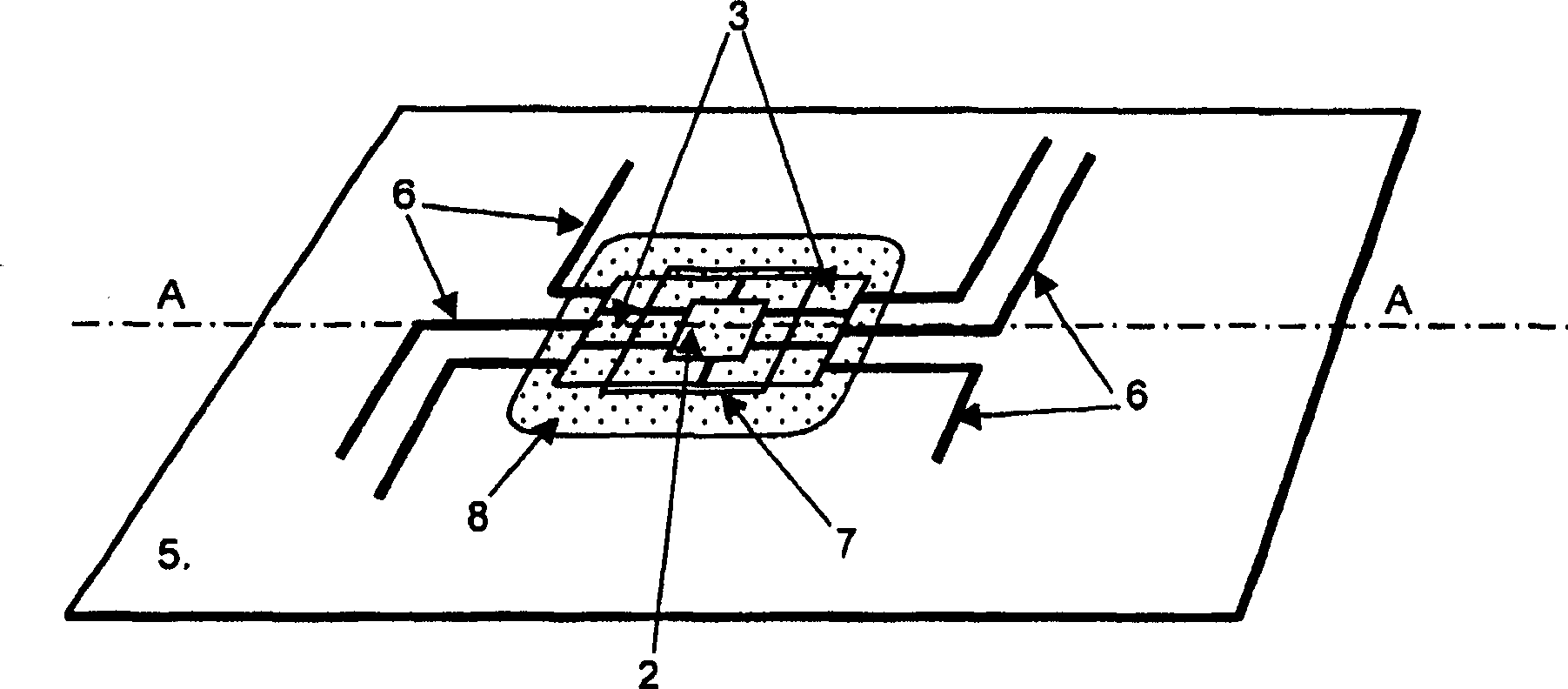

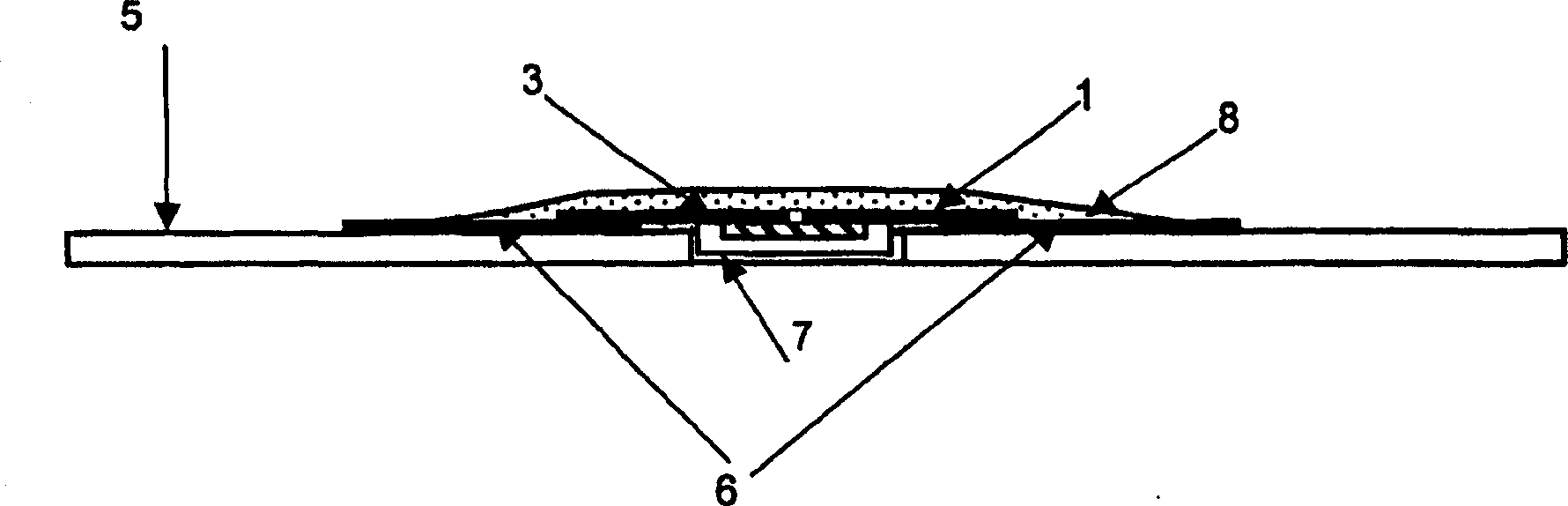

[0030] figure 2 and in image 3 The cross-section according to the axis A-A shown shows an embodiment of a transponder comprising the figure 1 Deformable thin substrate (5) of device (1) in . The upper surface of the substrate comprises tracks or conductive areas (6) that are etched, glued or printed, for example by screen printing. The coated part (4) of the device (1) is inserted into a cavity (7) formed by milling or cutting a window out of the substrate in order to reduce the final thickness of the transponder. The conductive traces (6) of the substrate are in contact with the conductive areas (3) of the device only by pressure without soldering or conductive glue. The approximately flat surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com