Mixed milling type silicon rubber anti structural agent

A technology of silicone rubber and structure control agent, which is applied in the field of structure control agent, can solve the problems of increasing tear permanent deformation and resilience, reducing tear strength, and single function, so as to improve tear strength and tear strength , to avoid the smelly effect of rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

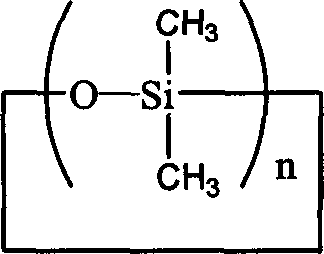

Method used

Image

Examples

Embodiment 1

[0026] Take 300g of D4 and 36g of VMC, dehydrate 16g by distillation under reduced pressure, then add 60g of dimethyldimethoxysilane, stir evenly, heat up to 80°C, add 21g of granular activated clay, stir and react at constant temperature for 1 hour, and then slowly raise the temperature to 100°C After 3 hours of continuous stirring and heat preservation reaction at ℃, the temperature was lowered to 64°C, and 18g of water was added to 64°C heat preservation reaction for 3 hours, then cooled to normal temperature, filtered to remove active clay, and the filtrate was distilled under reduced pressure to remove 29g of low-molecular substances, and finally obtained 351g of colorless , transparent liquid, the yield is 88%, and its viscosity is 14.0mm 2 / s, the hydroxyl content is 5.94% (mass percentage, the same below), the methoxy content is 4.12%, and the vinyl content is 2.62%.

Embodiment 2

[0028] Take 296g D4, 70g VMC and 60g dimethyldimethoxysilane, stir evenly, then heat up to 80°C, add 18g granular activated clay, stir and react at constant temperature for 1 hour, then slowly raise the temperature to 100°C, continue to stir and keep warm for 3 hours , lower the temperature to 64°C, add 25g of water at 64°C and keep it warm for 3 hours, then cool to normal temperature, filter to remove activated clay, and distill the filtrate at 150°C (-0.1Mpa) under reduced pressure to remove 38g of low-molecular substances, and finally obtain 382g of colorless, Transparent liquid with a yield of 84% and a viscosity of 12.5mm 2 / s, the hydroxyl content is 7.24%, the methoxy content is 3.53%, and the vinyl content is 5.10%.

Embodiment 3

[0030]Take 296g of DMC and 54g of VMC and first carry out vacuum distillation to remove 16g of DMC and water, then add 58g of dimethyldiethoxysilane, stir evenly, heat up to 100°C, add 25g of cation exchange resin, stir and react at constant temperature for 1 hour, and then Slowly raise the temperature to 110°C and continue to stir and keep warm for 3 hours, then cool down to 78°C, add 14g of water at 78°C and keep warm for 3 hours, then cool to normal temperature, filter to remove activated clay, and distill the filtrate under reduced pressure to remove 21g of low molecular weight. Finally obtain 353g colorless, transparent liquid, yield is 87%, and its viscosity is 20.5mm 2 / s, the hydroxyl content is 5.58%, the ethoxy content is 4.02%, and the vinyl content is 3.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com