Pressure and ultrahigh pressure generating method and device

A technology of ultra-high pressure and generation method, which can be used in pressure vessels, pipeline systems, fixed-capacity gas storage tanks, etc., and can solve the problems of difficulty in precise pressure control, high noise, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

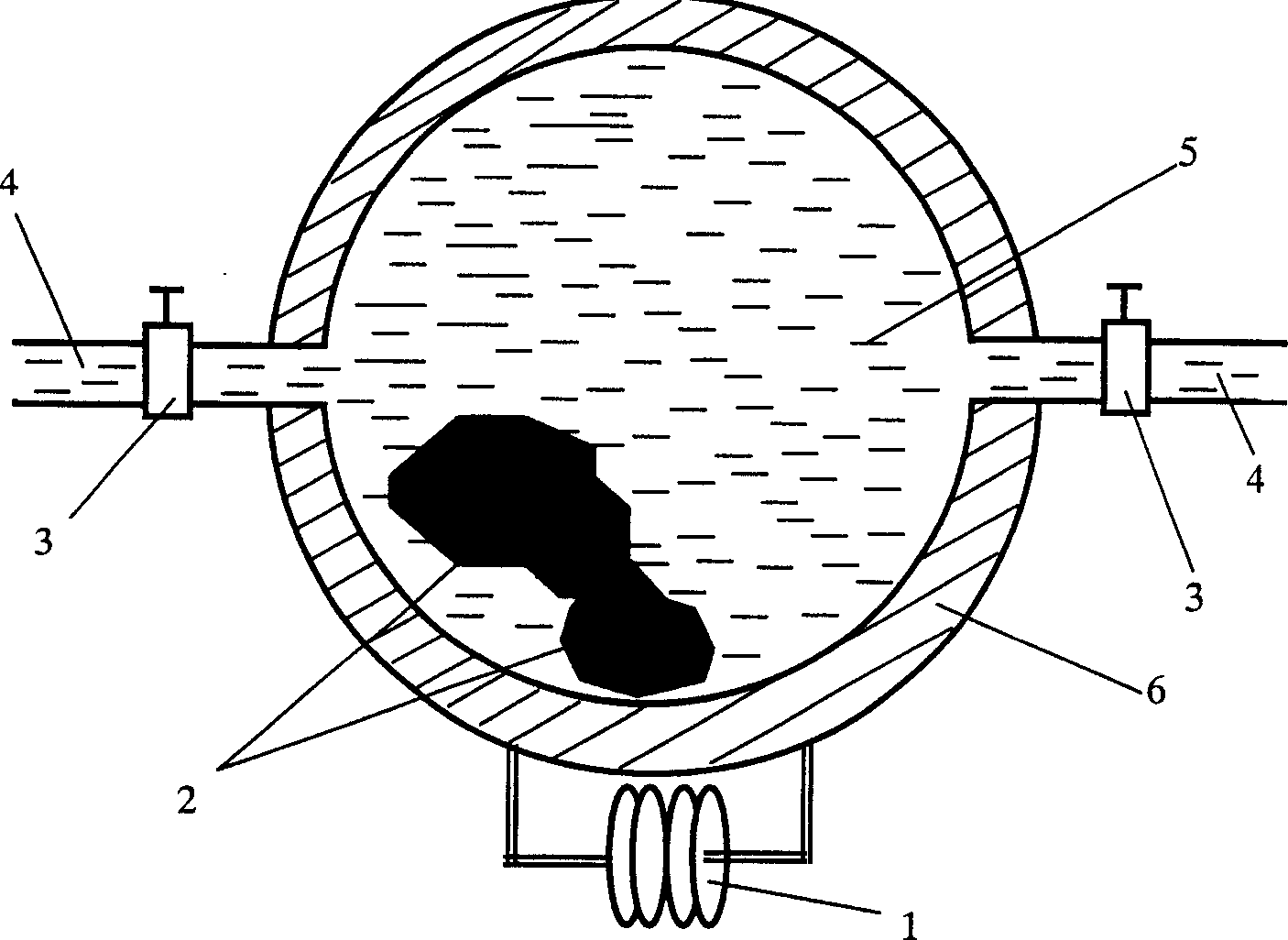

[0053] The present invention selects the most common liquid water as an example to further illustrate the principle of the present invention.

[0054] Chemically speaking, water is a highly polar molecule. In addition to the van der Waals force, there is a special force between molecules - hydrogen bond. The hydrogen bond is much smaller than the bond energy of the chemical bond, but stronger than the van der Waals force. It can combine water molecules to form many different irregular three-dimensional networks; at normal temperature, water is in a stable liquid state, and water vapor is a gas formed by evaporation of water or sublimation of ice; under normal pressure at 4°C (277.15K ), the density of water is maximum.

[0055] If the temperature is lowered, the water molecules will bond with each other to form a hexahedral structure, which is ice. The structure of ice is not flexible enough to be squeezed, so its volume is larger than that of the same amount of liquid water....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com