New acid preparing process with pyrite ore

A technology of pyrite and new technology, which is applied in pyrite roasting to produce acid and slag selection of iron ore, can solve the problems of non-compliance with free selection rules, lack of promotion and application, difficulty of slag beneficiation, etc., and achieve The effect of reducing roasting phenomenon, increasing unit yield, and reducing conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 Low-temperature roasting pyrite desulfurization test

[0019] The pyrite acid production process uses a small roasting furnace as the experimental device. The diameter of the roasting furnace is 0.36m and the height is 0.8m. Thermocouples are used as temperature measuring devices. The feeding amount is measured by an electronic scale. Can be adjusted manually. A square reduction chamber is built below the roasting chamber, and the reduction chamber specification is (length) 30cm×(width) 30cm×(height) 50cm.

[0020] The pyrite ore from Jianchang, Liaoning Province was selected as the raw material for acid production. The massive pyrite was crushed and mixed with powdered pyrite in equal parts and sieved. The maximum particle size of the sieved was less than 3mm, and the detected sulfur grade was 28%. Moisture 6%.

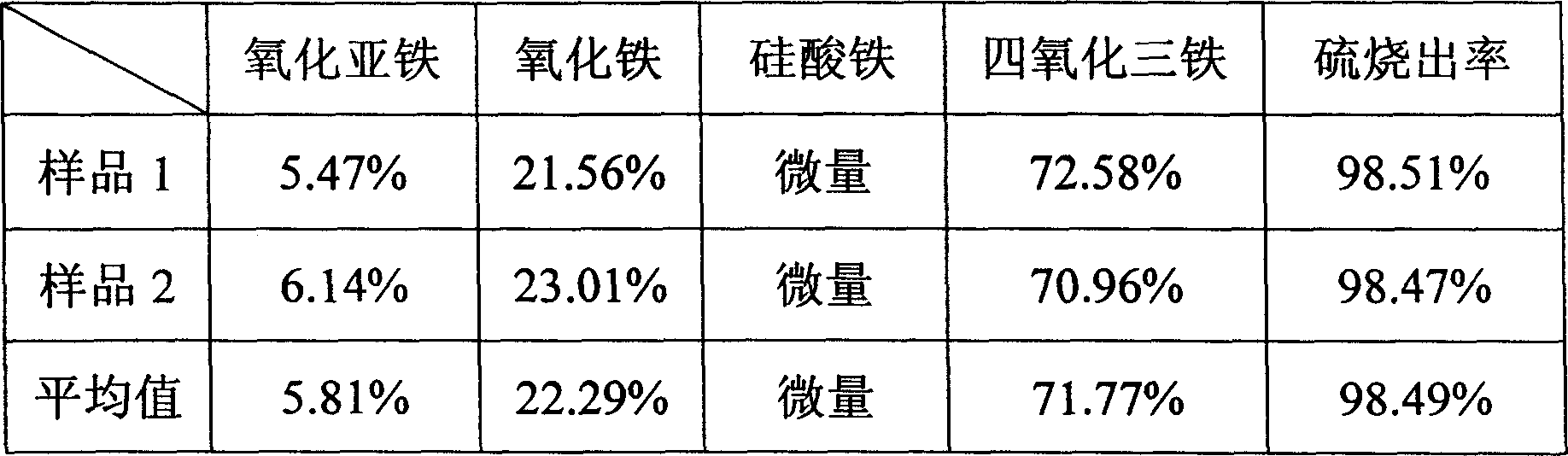

[0021] Adopt the roasting process provided by the present invention to roast pyrite to produce acid, and detect the oxidation rate of sulfur an...

Embodiment 2

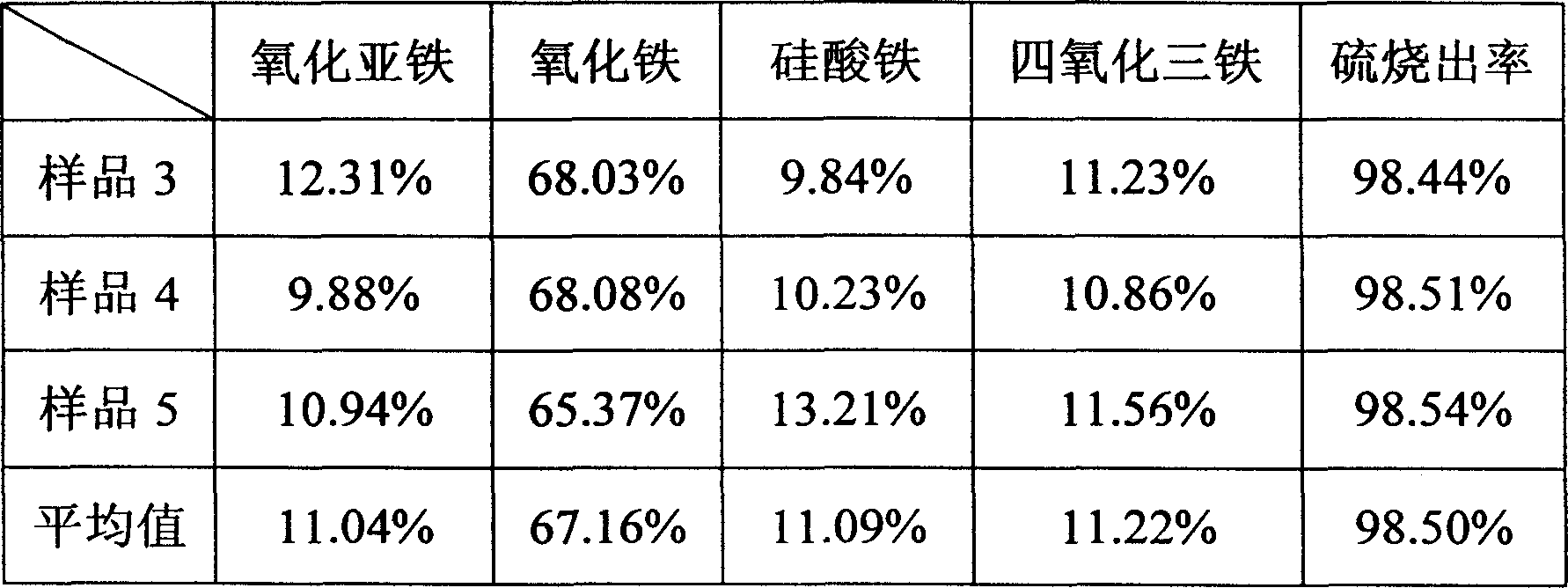

[0031] Embodiment 2 Slag reduction test

[0032] The roasting equipment and pyrite raw materials used are the same as in Example 1, and the slag of Example 1 is reduced through the reduction chamber provided under the roasting chamber, and the reduction temperature is controlled within the range of 550-570°C. And adopt different reducing agent to carry out reduction experiment:

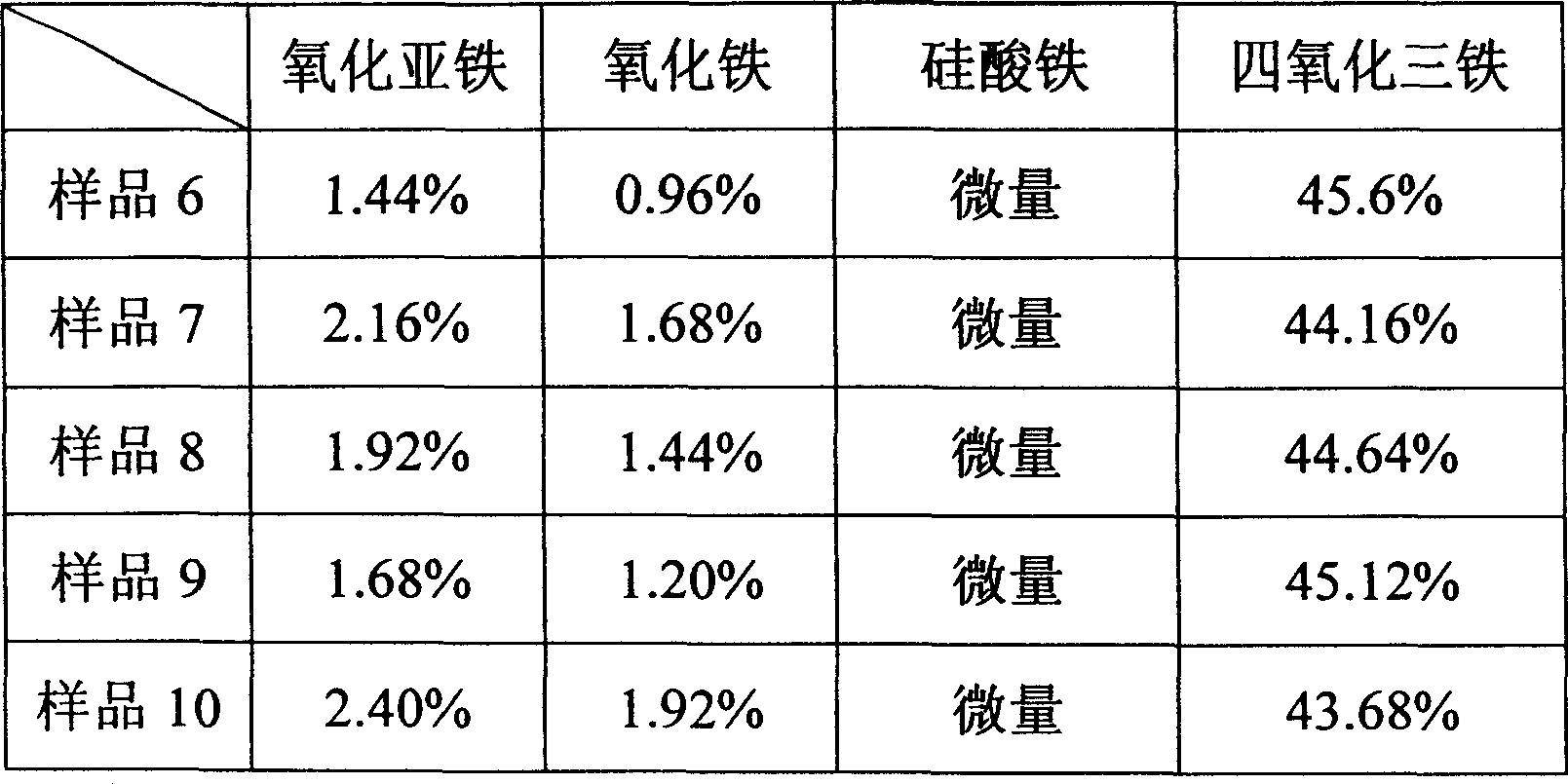

[0033] 1. Water gas is used as reducing agent to obtain slag sample 6. After testing, the iron grade in slag sample 6 is 48%, and the effective reduction component content of water gas is: CO 37%, H 2 50%. The throughput is 8.67 cubic meters per hour.

[0034] 2. Using blast furnace gas as a reducing agent to obtain cinder sample 7, the iron grade in cinder sample 7 was detected to be 48%, and the effective reducing component content of blast furnace gas was: CO 25.37%, H 2 2.11%. The throughput is 299.1 cubic meters per hour.

[0035]3. Using mixed gas as reducing agent to obtain cinder sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com