Method for removing hydrargyrum from coal burning boiler flue gas by ozone oxidation

A technology for ozone oxidation and coal-fired boilers, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve problems such as difficult large-scale popularization and application, reduced boiler efficiency, and low total mercury removal efficiency of coal-fired boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

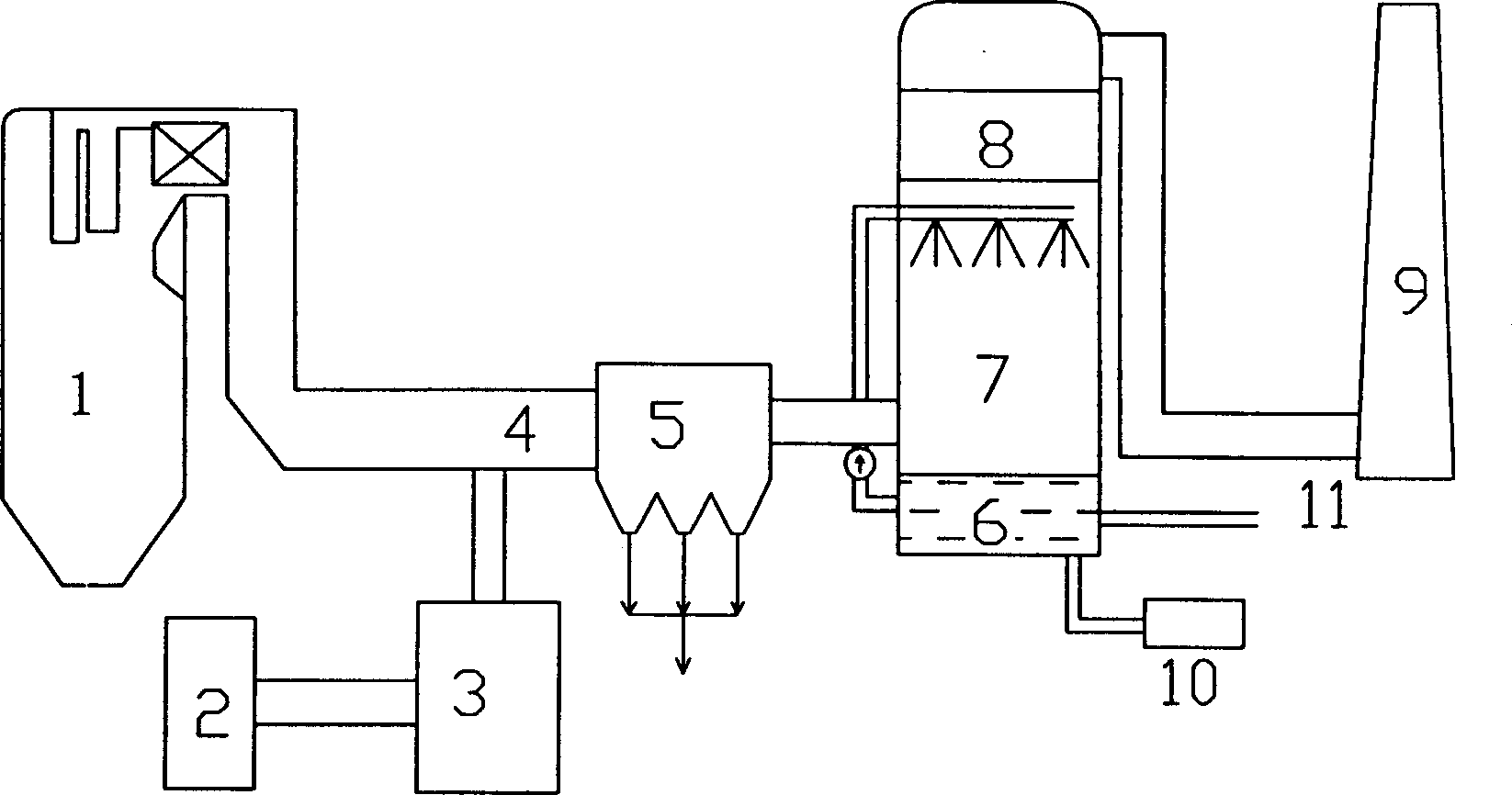

[0027] In specific embodiment 1, it is the arrangement mode of dust-laden wet scrubbing by ozone oxidation of coal-fired boiler flue gas to remove mercury, and the implementation method is as follows figure 1 shown. After the air is dried and purified, it is sent to the dry and filtered oxygen generator 2, and the generated oxygen is sent to the ozone generator 3 to prepare high-concentration ozone, and the ozone is sent to the dusty smoke with a temperature of 110°C before the electrostatic precipitator 5 after the air preheater Road, the amount of injection according to the flue gas NO concentration according to O 3 / NO molar ratio of 1.1:1 is adjusted from time to time to ensure a reaction time of at least 0.5s. The nozzle adopts porous grid injection, and the injection position is 1m away from the flue gas outlet of the air preheater. After passing through the electrostatic precipitator 5, it enters the wet scrubber 7, and the Hg 2+ Dissolving and absorbing, using H 2 ...

specific Embodiment 4

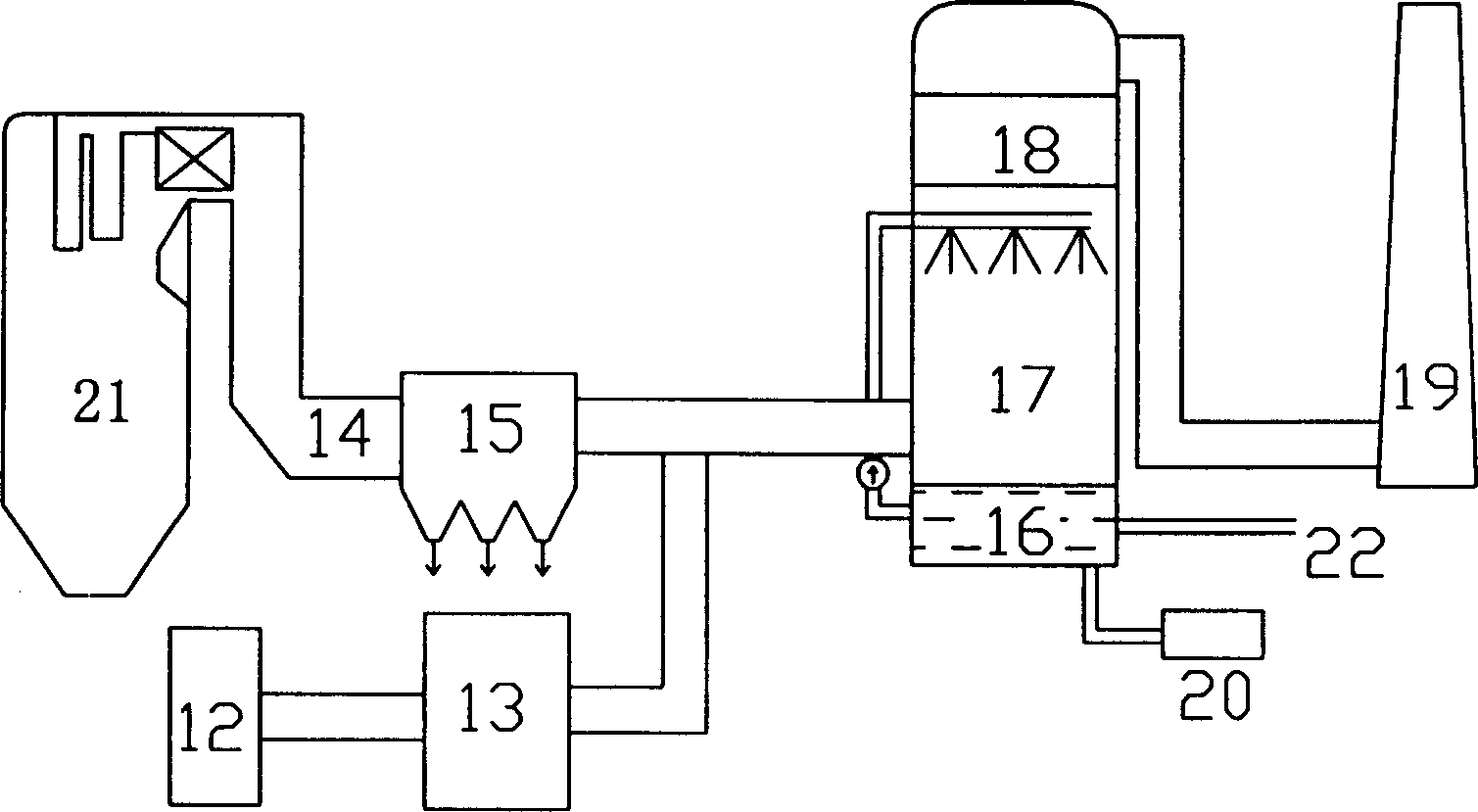

[0030] In the specific embodiment 4, it is the dust-free layout method of the ozone oxidation of coal-fired boiler flue gas to remove mercury, and the realization method is as follows figure 2 shown. Send ozone into the dust-free environment with a temperature of 110°C after the electrostatic precipitator, and the amount of ozone sent is O according to the concentration of NO 3 The / NO molar ratio is selected as 1.2:1. The injection position is after the dust collector and away from the washing tower inlet. The injection position can be determined according to the actual pipeline to ensure a response time of at least 0.5s. Divalent Hg 2+ Absorption and removal are carried out after entering the scrubber. The washing tower uses water or lye as the absorbent, and the washing tower is a spray tower or a packed tower. The lye used as absorbent is calcium hydroxide, but also potassium hydroxide or sodium hydroxide. Other steps are identical with specific embodiment 1.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com