Temperature measuring device of blast furnace crucible and its manufacturing method

The technology of a temperature measuring device and manufacturing method, which is applied in the direction of measuring device, inspection device, electric device, etc., can solve problems such as inability to measure temperature continuously, and achieve the effects of safe and reliable use, promising economic benefits, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

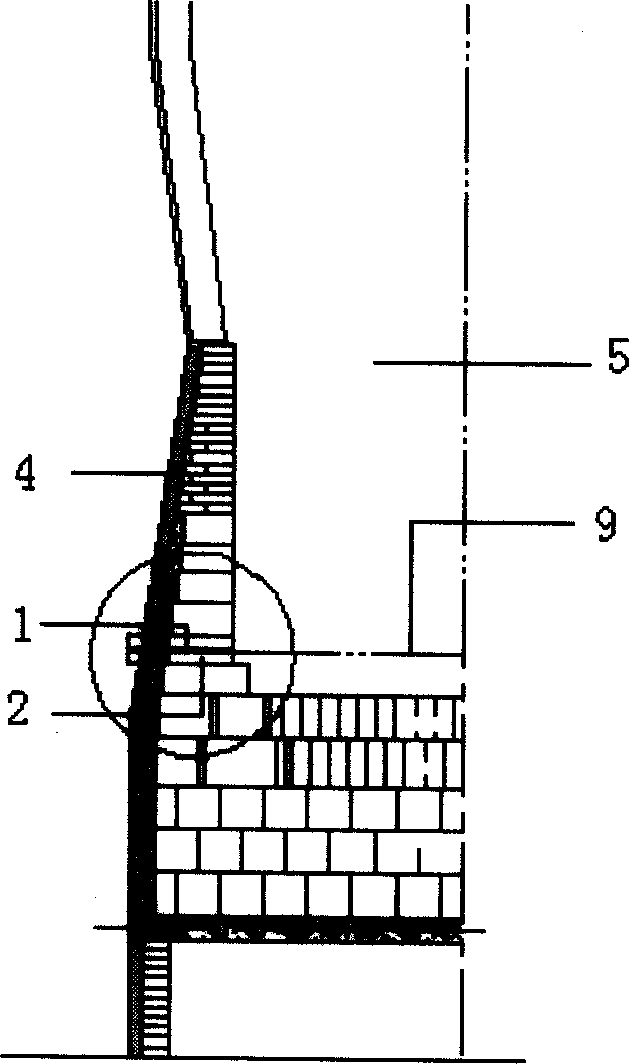

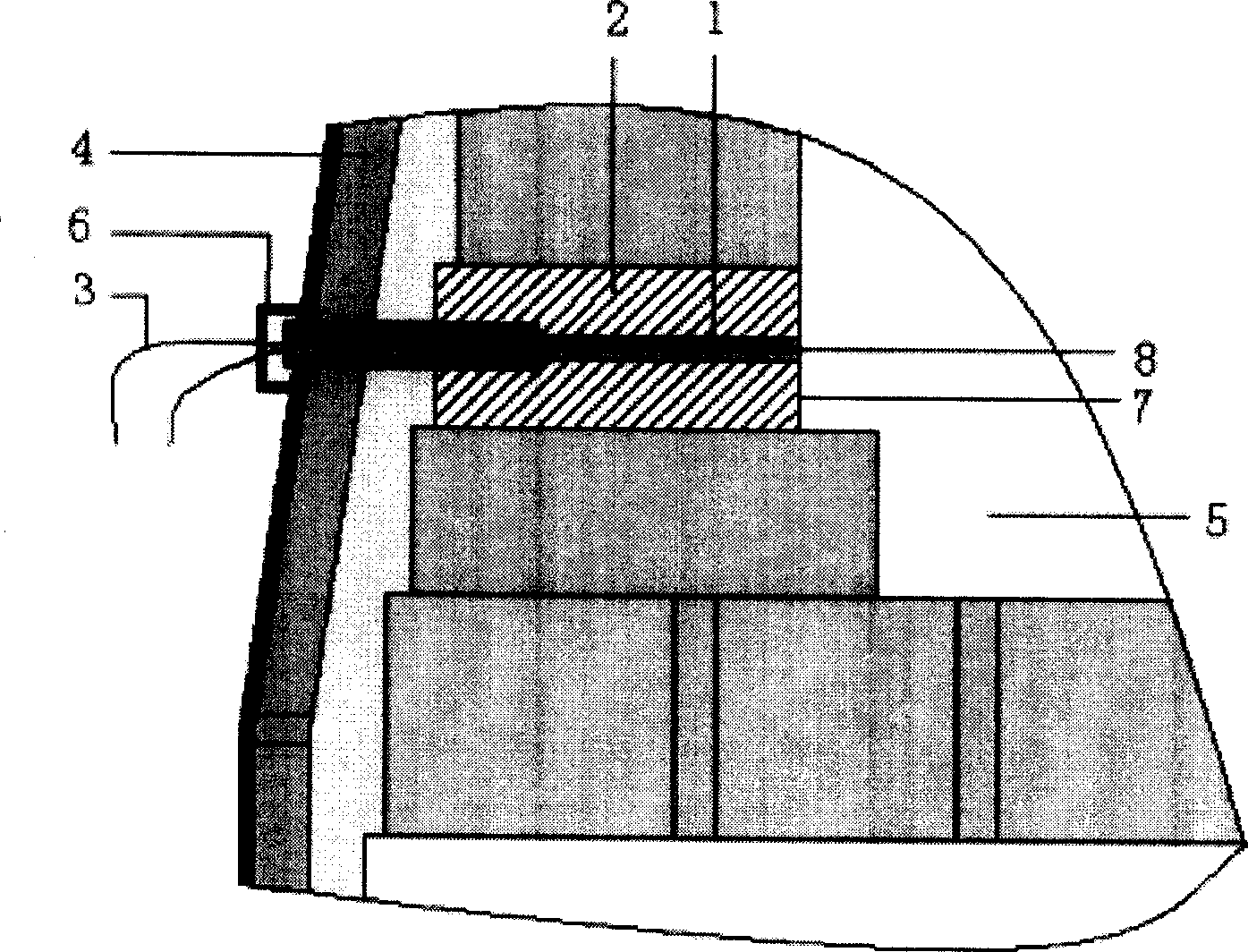

[0024] Depend on figure 1 , 2 It can be seen that the furnace hearth 5 is located at the lower part of the furnace body, the iron mouth is located in the furnace hearth 5, the outer layer of the blast furnace stave 4 is the furnace shell, the inner layer of the blast furnace stave 4 is a refractory brick, and the special pure graphite carbon Brick 2 is similar to other refractory bricks, just like other refractory bricks, but it should be built on the horizontal line 9 of the center of the blast furnace taphole; thermocouple 1 is located on the central axis of pure graphite carbon brick 2, and the front end of thermocouple 8 is connected with the front end of pure graphite carbon brick. 7 flush; can directly measure the temperature in the hearth; thermocouple 1 uses double graphite carbon fiber thermocouple to make full use of its high temperature resistance; in order to prevent leakage, connect the double graphite carbon fiber thermocouple 1 and pure graphite carbon brick 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com