Edible membrane of cross-linking cereal gliadin and its preparation method

A technology of gliadin and wheat gliadin, which is applied in food preparation, food science, application, etc., can solve the problems of difficult thermoforming of protein materials, thermal decomposition of proteins, etc., and achieve high hydrophobicity and anti-aging performance, The production process is simple and the effect of easy processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

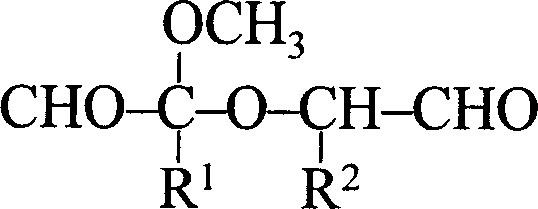

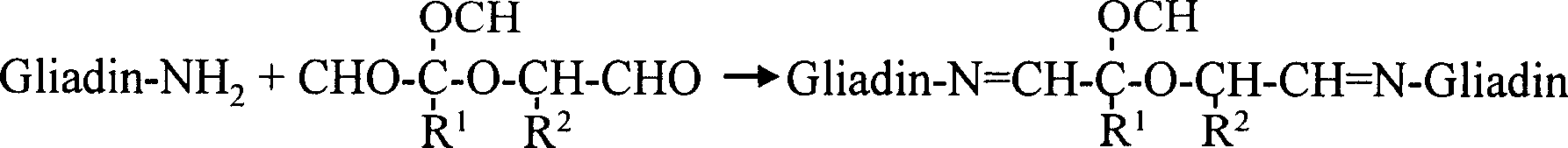

[0042]The preparation method of cross-linked cereal prolamin edible film using wheat prolamin as raw material is as follows: Weigh 100g of gluten powder, add 500ml of 60% ethanol / water mixed solvent, and extract wheat at 30°C for 2h Glamin, centrifuged to obtain supernatant, add appropriate 60% ethanol / water mixed solvent to make the concentration of prolamin 50mg / ml, take 100ml of prolamin solution, add 1g 1,2-propanediol, 25mg stearin Acid, 2.5mg tert-butylhydroxyanisole and 50mg D′-methoxydiglycol aldehyde, stirred evenly to obtain a film-forming solution, poured on a smooth plastic plate, and after the solvent evaporated, heat-treated at 50°C for 1h, The film is peeled off to obtain a cross-linked gliadin edible film.

Embodiment 2

[0044] The preparation method of cross-linked cereal prolamin edible film using hordein as raw material is as follows: Weigh 100g of barley grain powder, add 500ml of 90% ethanol / water mixed solvent, and extract wheat alcohol by electromagnetic stirring at 50°C for 2h Dissolve the protein, centrifuge to obtain the supernatant, add an appropriate 90% ethanol / water mixed solvent to make the concentration of the prolamin 100mg / ml, take 100ml of the prolamin solution, add 10g 1,3-propanediol, 100mg hydroxystearin acid, 10mg tea polyphenols, 10mg ethyl sorbate and 700mg D′-methoxy-D-hydroxymethyl diglycol aldehyde, stir evenly to obtain a film-forming solution, pour it on a smooth plastic plate, and wait for the solvent to evaporate completely Finally, heat treatment at 120° C. for 30 minutes, and peel off the film to obtain a cross-linked gliadin edible film.

Embodiment 3

[0046] The preparation method of cross-linked cereal gliadin edible film is prepared by using oat gliadin as raw material: Weigh 10g oat gliadin, add it to 70% ethanol / water mixed solvent, and make the mass concentration 80mg / ml Add 5g of diethylene glycol, 80mg of n-butyl stearate, 8mg of tocopherol, 80mg of sorbic acid butyl p-hydroxybenzoate and 300mg of L′-methoxyl-L-methyl diglycol aldehyde, and stir well The obtained film-forming solution is poured on a smooth plastic plate, and after the solvent is volatilized, it is heat-treated at 100°C for 45 minutes, and the film is peeled off to obtain a cross-linked gliadin edible film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com