Guarding device for manualy blowing lighting fixture

A technology of safety protection devices and lamps, which is applied in glass blowing, manufacturing tools, blowpipes, etc., can solve the problems affecting the physical and mental health of operators, the inability to control harmful gases, and the inability to be reused, achieving high resource reuse rates, Improved working environment and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

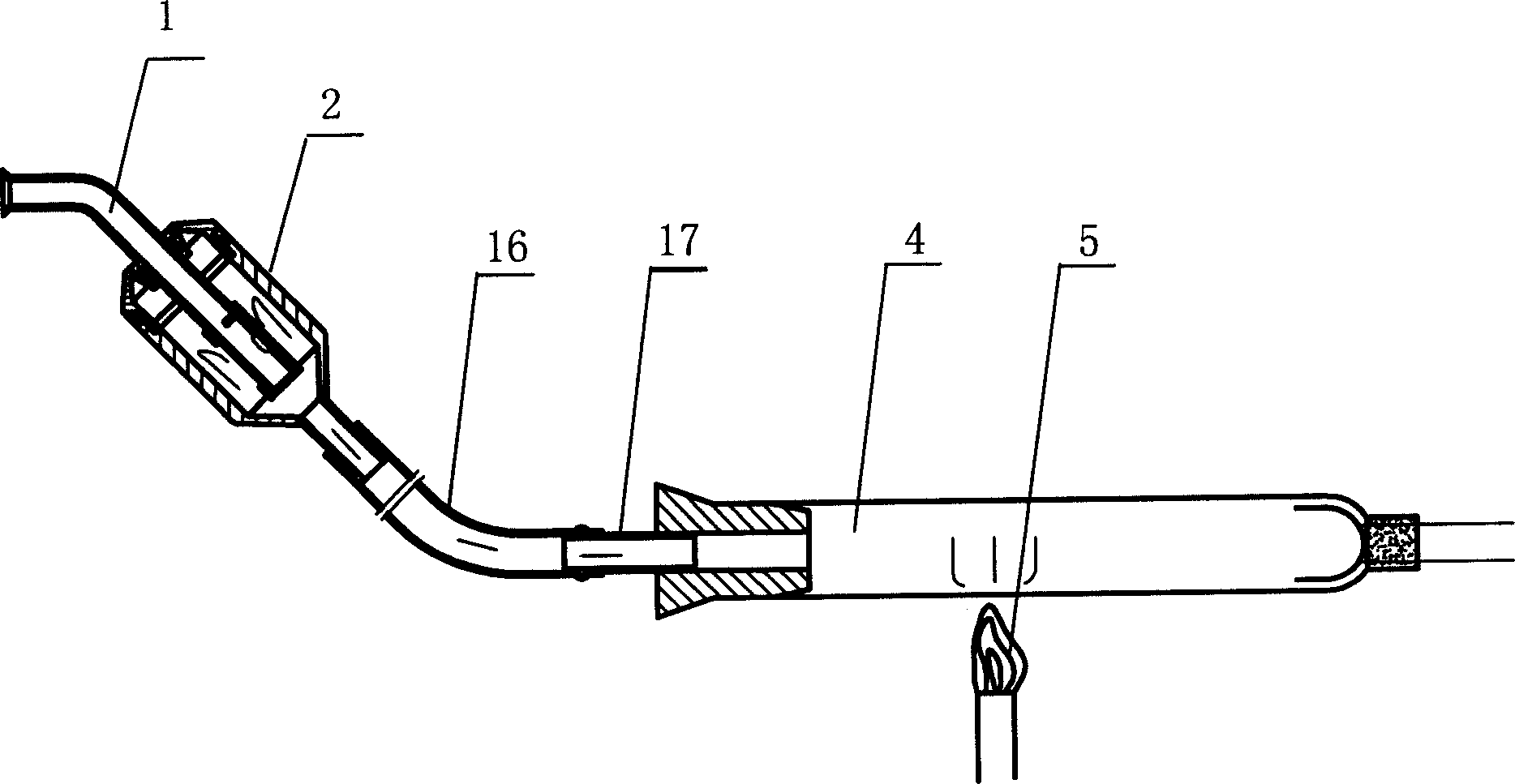

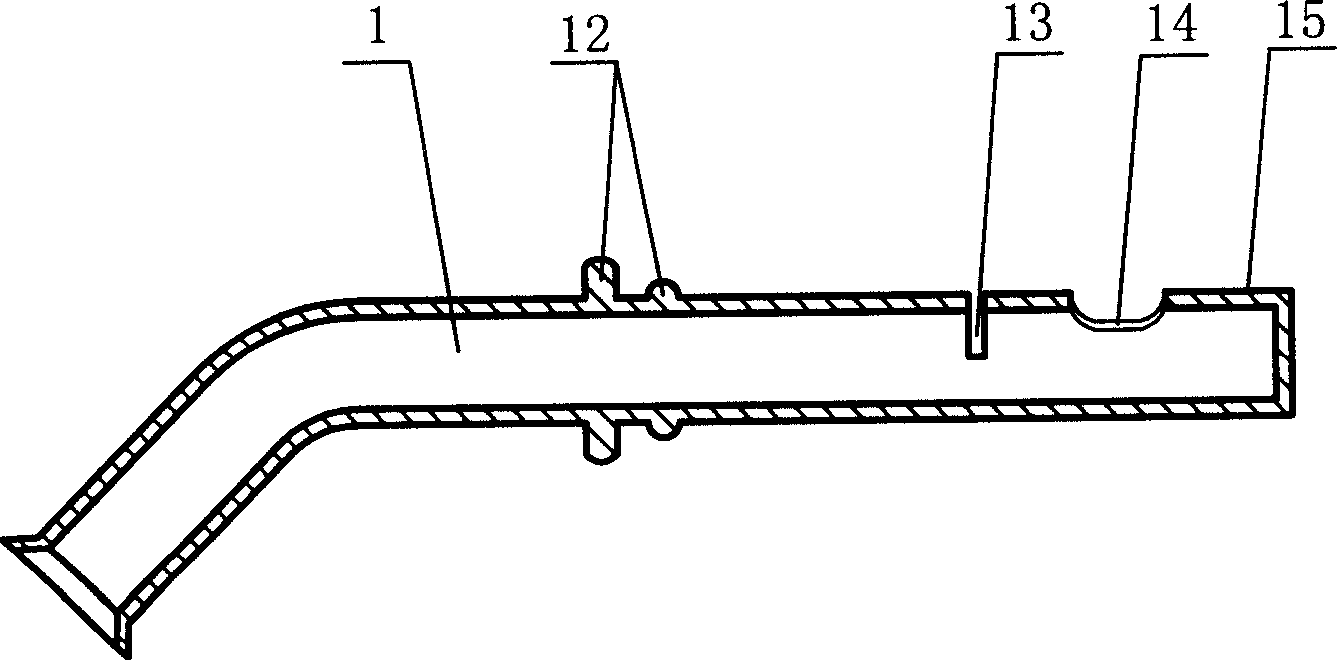

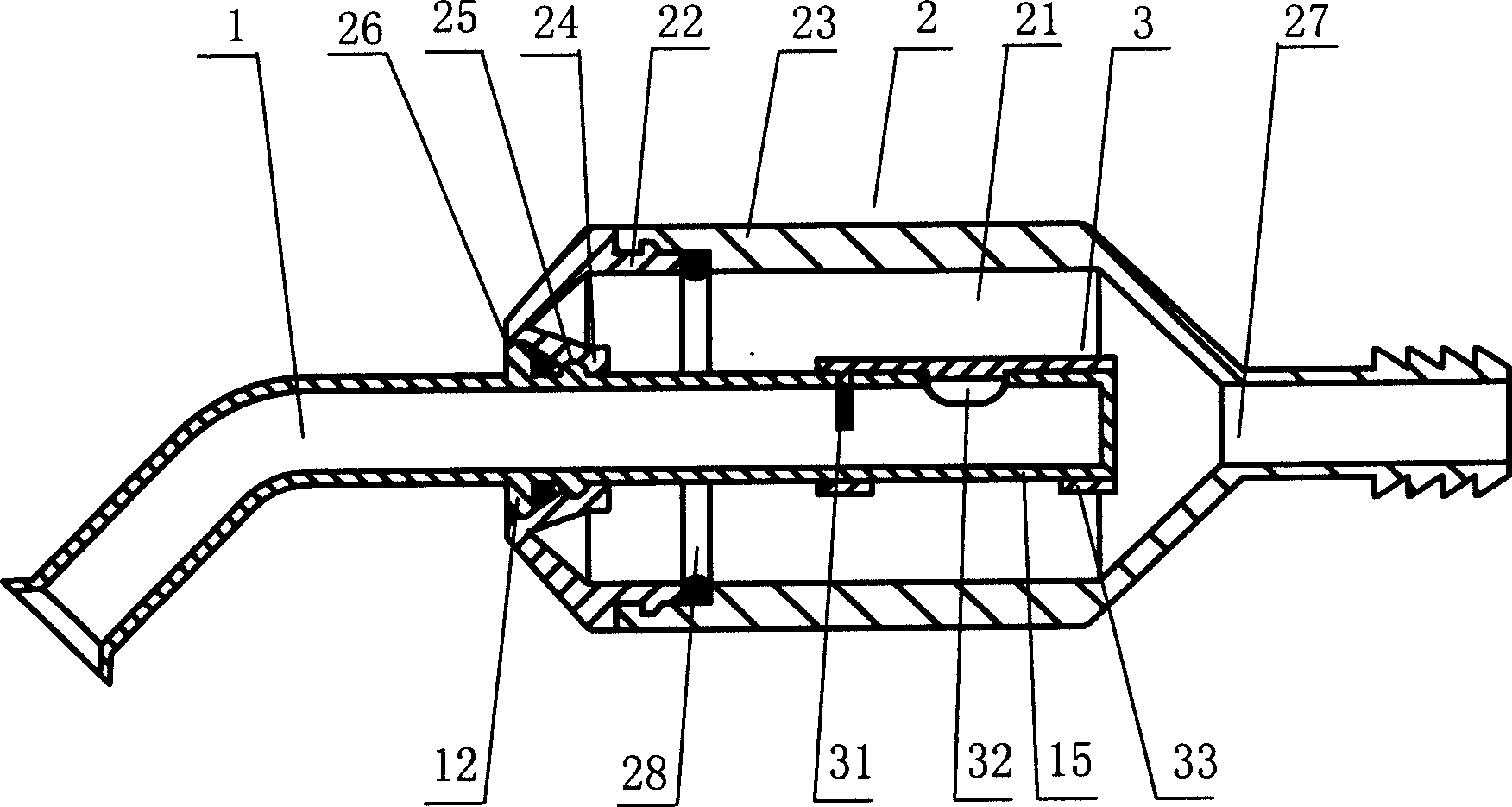

[0022] It can be seen from the accompanying drawings that a safety protection device for artificially blown lamps includes a hose 16 connected to the pipe-shaped air nozzle 1 and the connecting end 15 of the pipe-shaped air nozzle, and is fixedly connected to the hose 16 and the lamp 4 or the lamp. Connecting pipe 17 between light tube 4 seals, the present embodiment uses fluorescent tube 4. In order to prevent the fluorescent powder in the fluorescent tube 4 from being inhaled by the human body together with harmful water vapor and harmful mercury vapor after being evaporated by the high-temperature processing of the blower flame 5 during the process of bending the neon light, it is easy to cause respiratory diseases Therefore, a ventilation device 2 is added to the connecting end 15 of the tubular air nozzle 1 in the existing blown lamp structure. The gas storage chamber 21 of this ventilation device 2 is formed into a transparent airtight body by two semi-tubular shells 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com