Rare earth three primary colours luminescent material transferring violet ray of violet ray diode to white ray

A technology of luminescent materials and diodes, which is applied in luminescent materials, electrical components, electric solid devices, etc., can solve the problems of high cost of white LEDs, difficulty in circuit control, and difficulty in obtaining phosphor powder, etc., and achieve high luminous efficiency, low cost, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

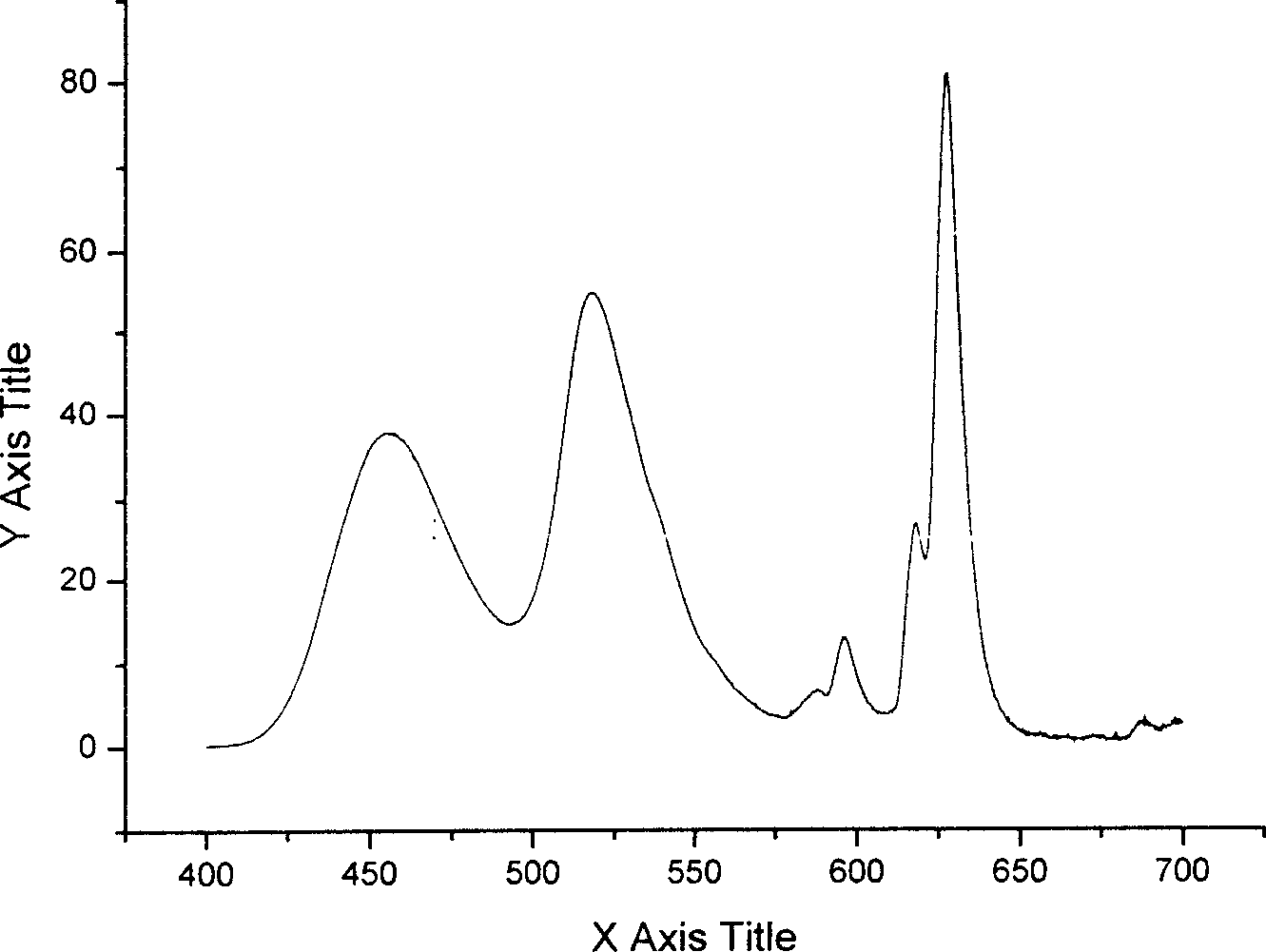

Image

Examples

Embodiment 1

[0016] Embodiment 1 is selected as: Y 2 o 3 (4N) 18.587%

[0017] Eu 2 o 3 (4N) 0.906%

[0018] S (high purity) 40.25%

[0019] NaCO 3 (AR) 40.257%

[0020] After mixing and grinding the above materials, put Al 2 o 3 Or in a quartz crucible, sinter at a high temperature of 1100°C or 1200°C or 1300°C or 1350°C in a sulfur-containing atmosphere for 1 hour or 1.5 hours or 2 hours or 2.5 hours or 3 hours (or the temperature and time within the above range All belong to the protection content of the present invention), take out the powder after cooling, select the powder, post-processing, both obtain the material that emits red light.

Embodiment 2

[0021] Embodiment 2 is selected as: Gd 2 o 3 (4N) 19.822%

[0022] Eu 2 o 3 (4N) 0.892%

[0023] S (high purity) 39.643%

[0024] NaCO 3 (AR) 39.643%

[0025] Sintering method step is the same as embodiment 1.

Embodiment 3

[0026] Embodiment 3 is selected as: La 2 o 3 (4N) 18.587%

[0027] Eu 2 o 3 (4N) 0.906%

[0028] S (high purity) 40.254%

[0029] NaCO 3 (AR) 40.253%

[0030] Sintering method step is the same as embodiment 1.

[0031] (2) The second part chemical formula (2) of the present invention takes M 3-x-y (PO 4 ) 2 ·(SrCl 2 ·6H 2 O) x :Eu y 2+ The components are prepared according to the structural formula and the blue light-emitting material, and the reagent materials are weighed according to the following measurements:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com