Carbon tube nanometer tube figuring technique

A technology of carbon nanotubes and process methods, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., and can solve problems such as limitations and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Patterned deposition of carbon nanotubes on a silicon substrate:

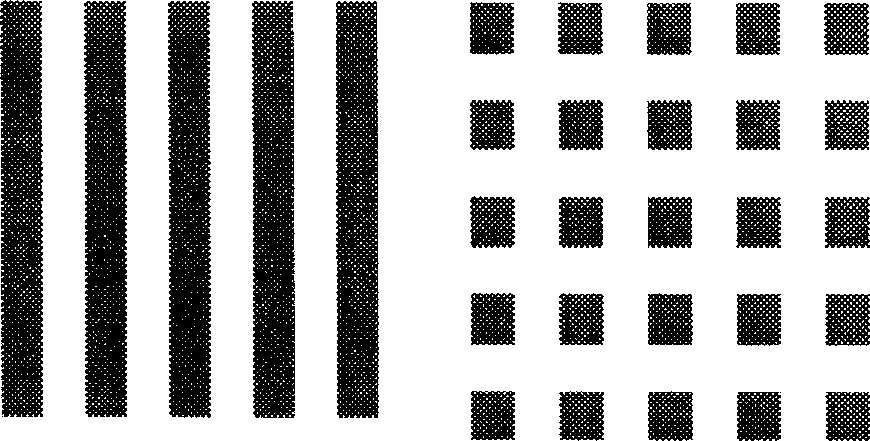

[0031] Single crystal silicon wafer N(100) is used as the substrate, and a layer of Megaposit SPR6112B photoresist is coated on it, and the photoresist is exposed according to the pre-designed stripes and dot matrix patterns of different sizes, and the silicon wafer exposed after exposure and development Partially assemble the OTS methyl surface self-assembly film, then soak it in acetone to remove the remaining photoresist, and then assemble the APTES amino surface self-assembly film on the silicon wafer after the glue removal. This results in the formation of a patterned self-assembled membrane surface (e.g. figure 1 shown).

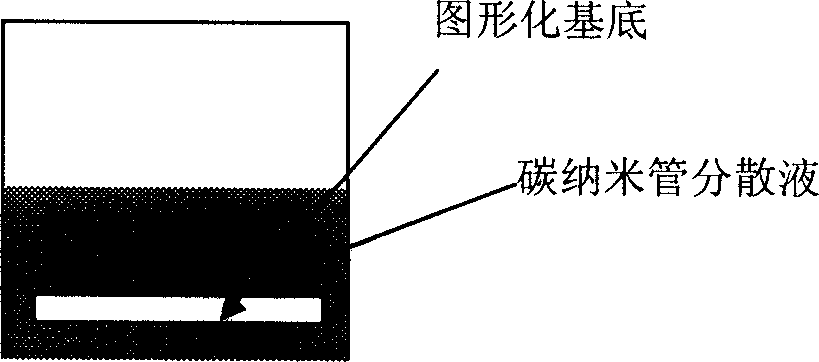

[0032] Immerse the patterned function-treated silicon substrate into SDS aqueous solution or DMF carbon nanotube dispersion liquid deposition (such as image 3 Shown) for sixteen hours, after taking it out, wash it with deionized water or anhydrous methanol respectively, and dr...

Embodiment 2

[0034] Patterned deposition of carbon nanotubes on an aluminum substrate for electrodes:

[0035] Using single crystal silicon wafer N(100) as the substrate, a layer of Al is sputtered on the cleaned silicon wafer, and then a layer of Megaposit SPR6112B photoresist is coated on the Al, according to different sizes of stripes and dot matrix patterns designed in advance Expose the photoresist, then corrode the exposed part of Al (phosphoric acid etching), assemble the OTS methyl surface self-assembly film on the part of the silicon wafer exposed by corroding Al, and then soak in acetone to face the photolithography of the Al surface The glue is removed, and then the APTES amino surface self-assembled film is assembled on the Al after the glue has been removed, to form the graphics of different surface self-assembled films (such as figure 1 shown).

[0036] Immerse the patterned substrate in SDS aqueous solution or DMF carbon nanotube dispersion for 16 hours, then take it out, w...

Embodiment 3

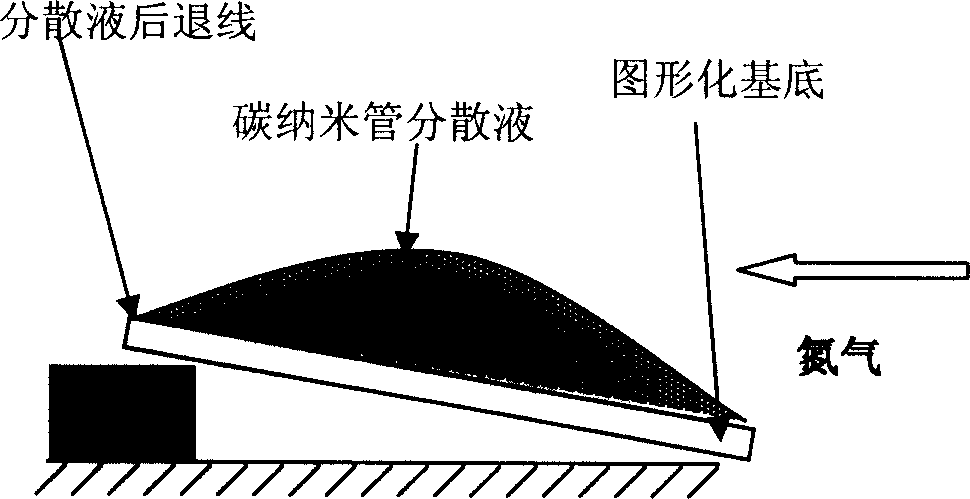

[0038] A patterned carbon nanotube film is obtained by a patterned casting process of carbon nanotubes on an aluminum electrode substrate.

[0039] Use single crystal silicon wafer N(100) as the substrate, sputter a layer of Al on the cleaned silicon wafer, and then coat a layer of Megaposit SPR6112B photoresist on the Al, and design stripes and dot matrix patterns of different sizes according to your own design Expose the photoresist, then corrode the exposed part of Al, assemble the OTS methyl surface self-assembly film on the part of the silicon wafer exposed by corroding Al, and then soak in acetone to remove the photoresist on the Al surface, Hydroxylation again to form a hydrophobic OTS film and a hydrophilic aluminum pattern (such as figure 1 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com