Gas sensor and method for manufacturing the same

A gas sensor, reference gas technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as difficulty in precise combustion control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0077] The following various experiments were carried out to verify the effects of the invention.

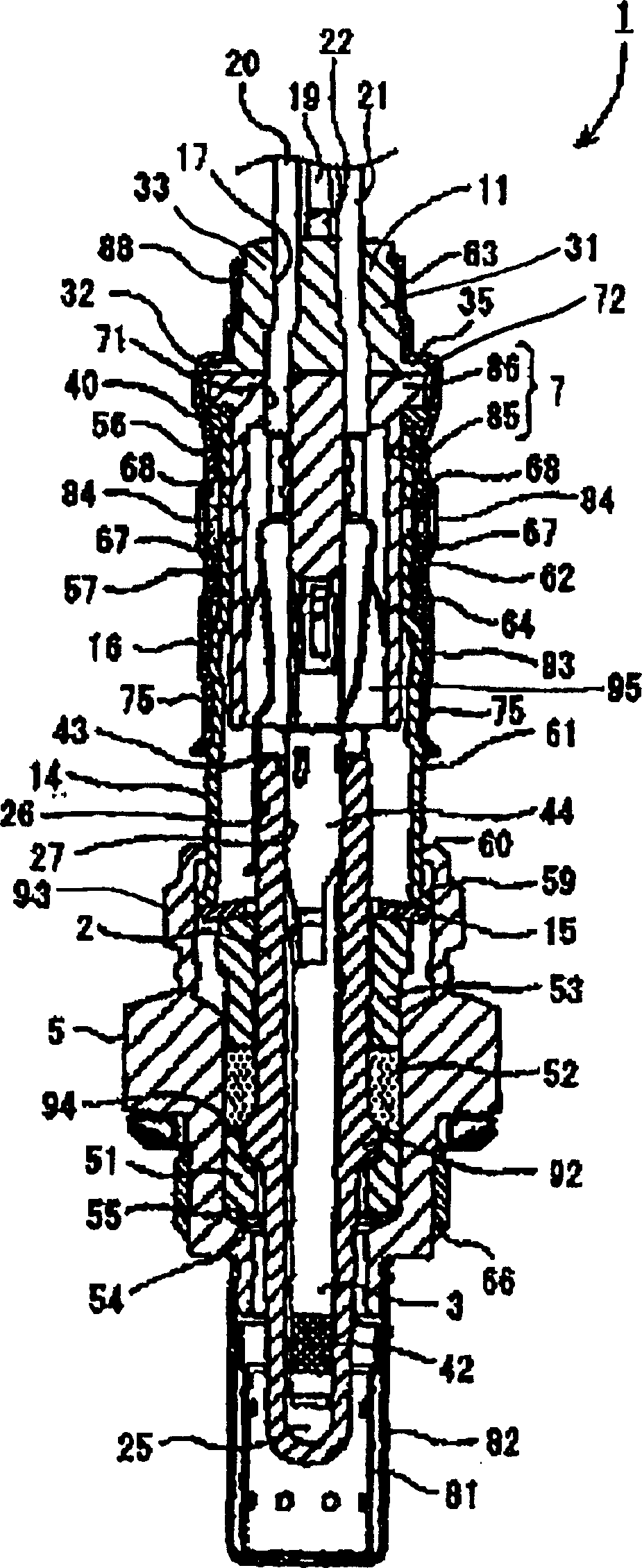

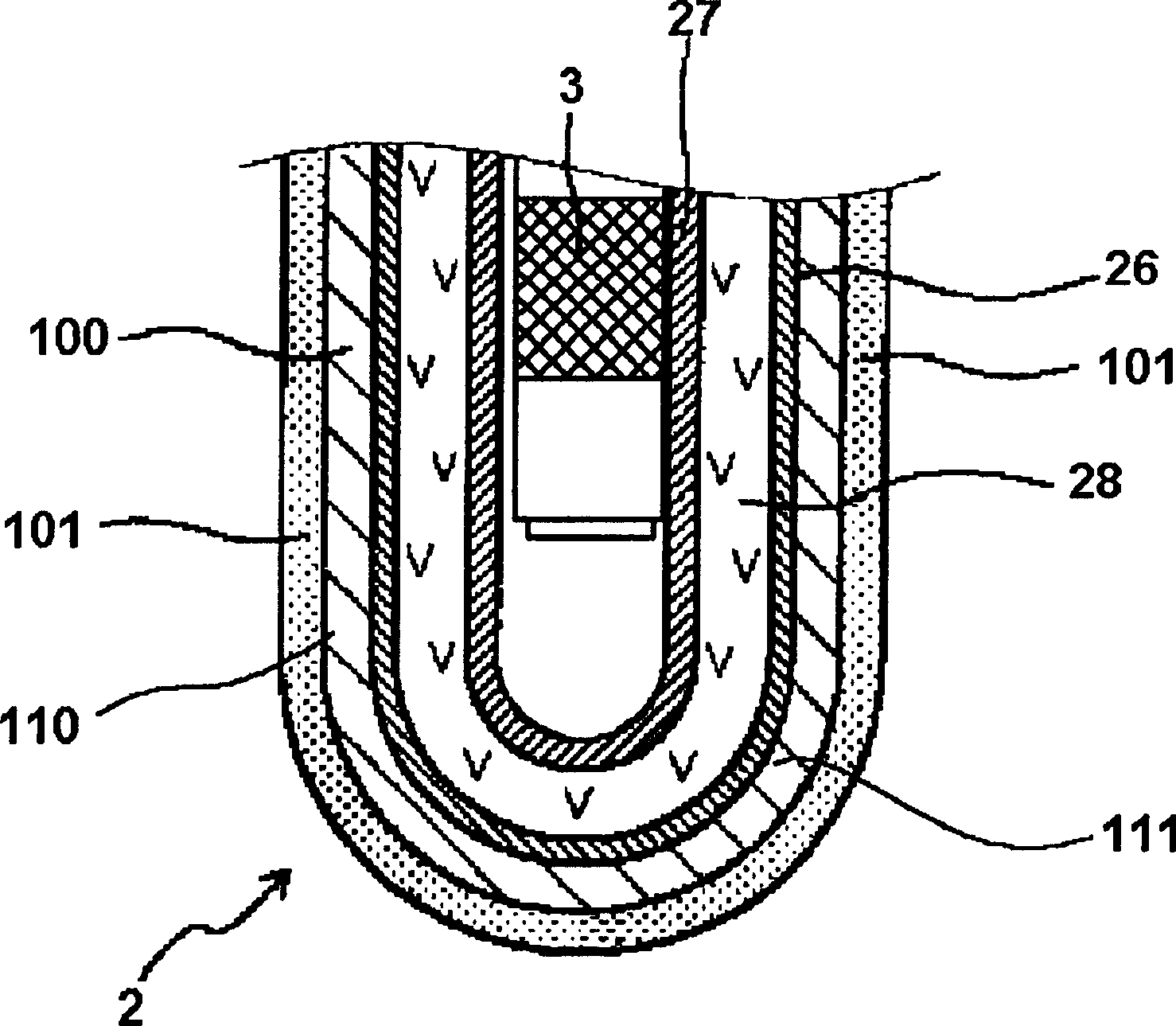

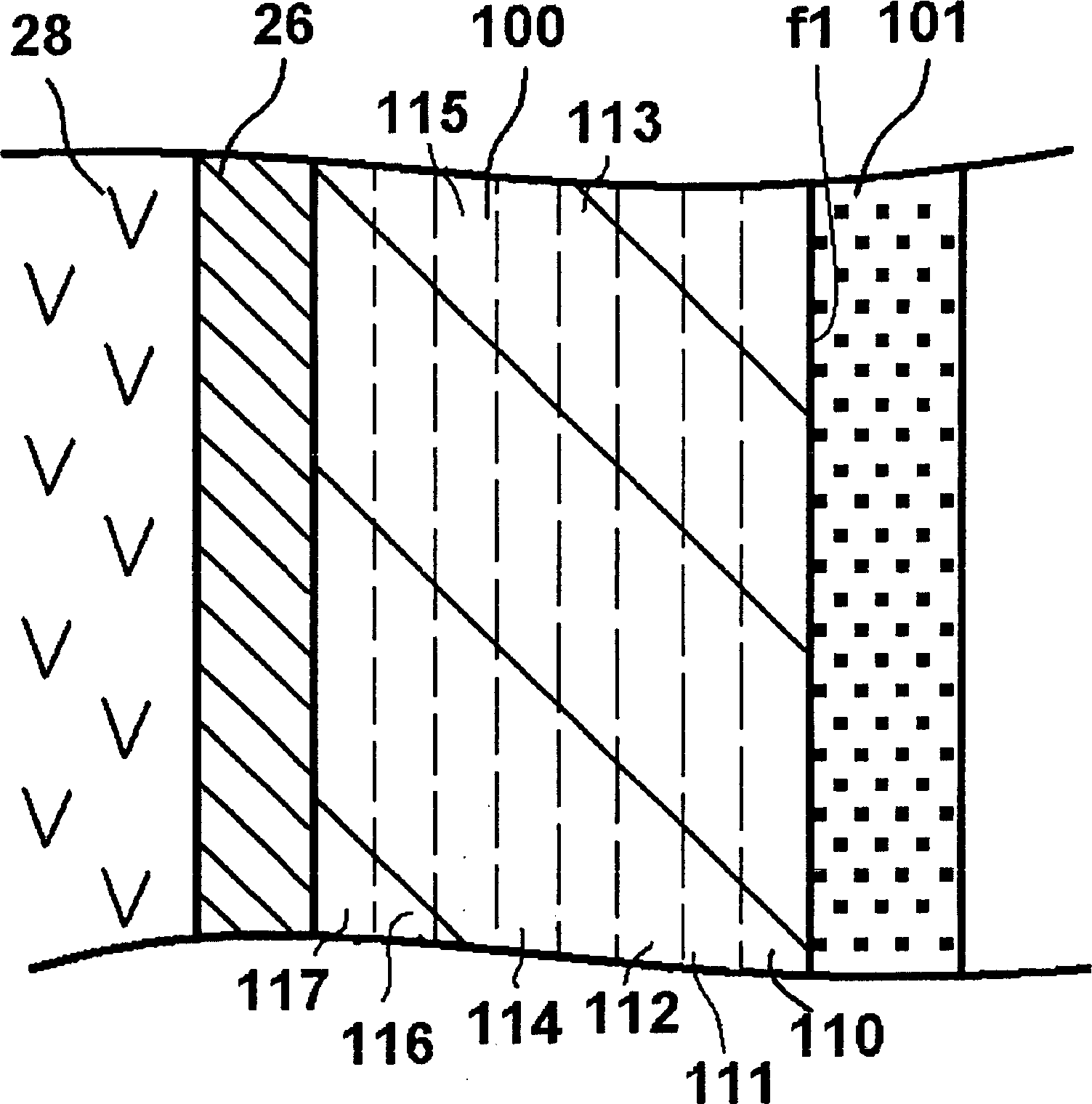

[0078] Prepare in the following manner with figure 2 Various test pieces of the sensor element 2 of the shape shown in . First, zirconia having 5 mol % of yttrium oxide added thereto was pelletized and formed into a bottomed cylindrical shape. This bottomed cylinder was fired at 1,300° C. for 2 hours to prepare solid electrolyte layer 28 . Next, solid electrolyte layer 28 is plated with platinum on its outer circumference and its inner circumference to form outer electrode layer 26 and inner electrode layer 27 . Then, the surface of the external electrode layer 26 was plasma sprayed with Al-Mg spinel to form a porous body having a thickness of 200 μm of the electrode protection layer 100 .

[0079] In Example 1, the porous body of the electrode protective layer 100 was then immersed in H in vacuum. 2 PtCl 6 aqueous solution for 10 minutes. The H 2 PtCl 6 The aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com