Low-temperature polysilicon thin film transistor and method for manufacturing its channel layer

A technology of thin-film transistors and low-temperature polysilicon, which is applied in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as the inability to reduce the man-hours for forming polysilicon thin films, high overall transistor costs, and expensive equipment, etc., to improve work efficiency, Effect of low leakage current and improved mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

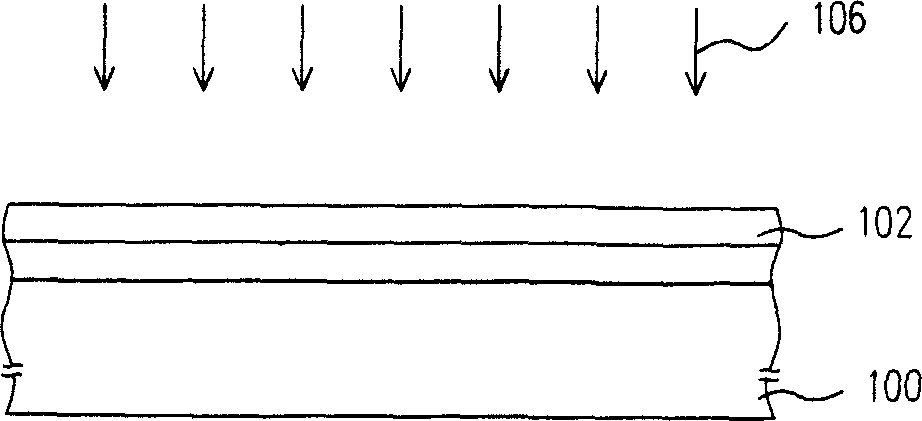

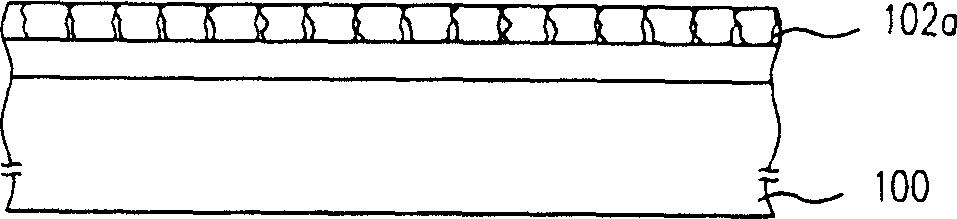

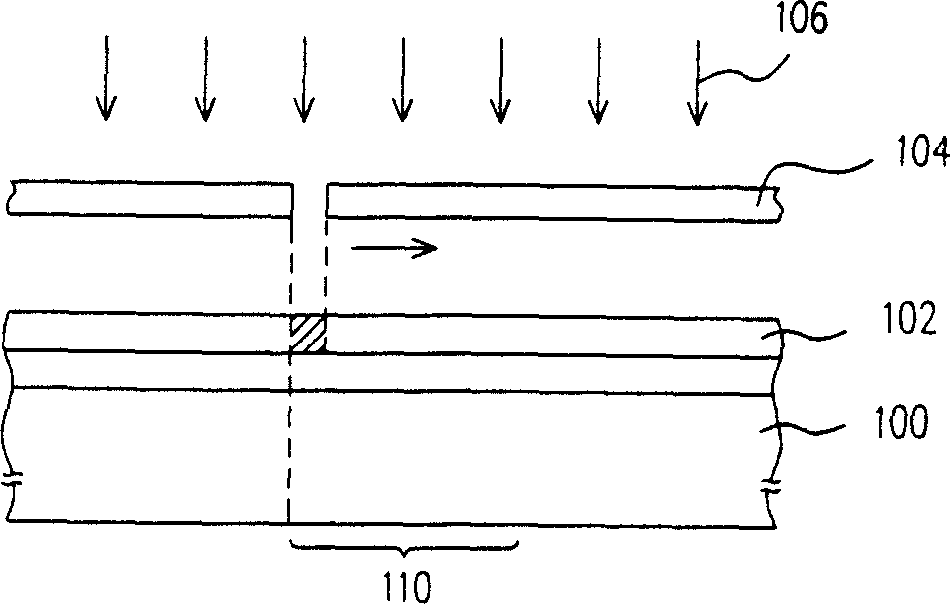

[0031] In the present invention, before the process of converting the amorphous silicon film into a polysilicon film, the sacrificial layer under the area of the amorphous silicon film intended to be used as a polysilicon channel in the subsequent process is removed to form a gap region with lower thermal conductivity than the two sides. So that the crystallization rate of the silicon grains above here is slower than that of the silicon grains in the regions on both sides, so that the grains grow laterally from the two sides to the center, and grow into larger-sized crystals in the channel region. grain. The following examples are used to illustrate the principles of the present invention, so that those skilled in the art can better understand the present invention, but are not intended to limit the present invention.

[0032] image 3 Shown is a schematic cross-sectional view of a low temperature polysilicon thin film transistor according to a preferred embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com