Improved circulation type molten steel vacuum refining method and device

A vacuum refining and circulating technology, which is applied in the field of improved circulating molten steel vacuum degassing refining method, smelting and molten ferroalloy processing, can solve the problem of not being able to effectively improve the removal efficiency of inclusions in steel and meet the requirements of Increase the treatment of steel types and other issues to achieve the effects of increased probability, reduced air bubbles and inclusions, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

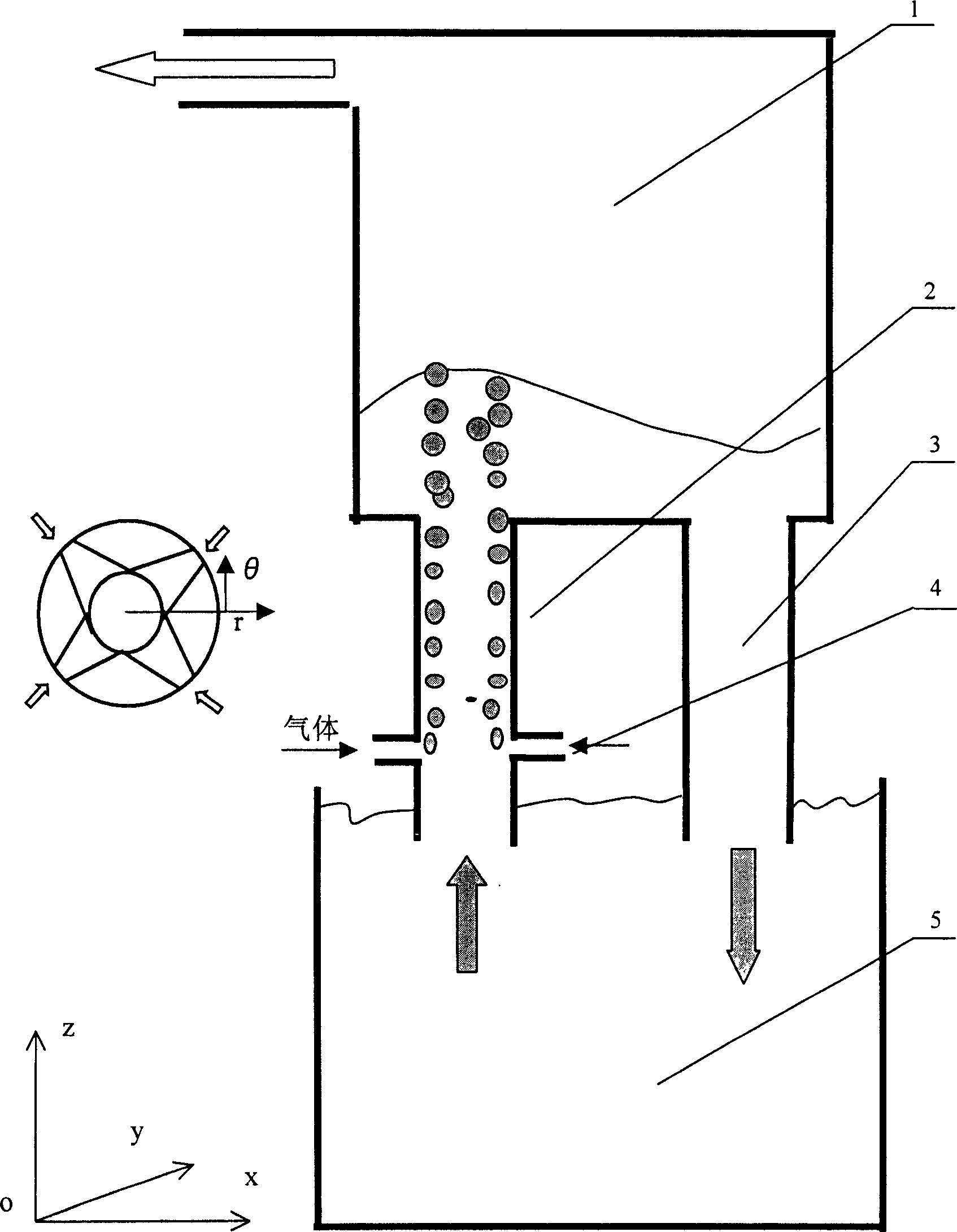

[0022] Embodiment 1: Improved circulation type molten steel vacuum refining method and device with electromagnetic stirrer

[0023] Such as figure 2 As shown, outside the rising tube 2 of the vacuum chamber 1 of the existing RH, a water-cooled electromagnetic winding 6 fixed to the outer wall of the rising tube is installed. So that the electromagnetic force can drive the molten steel to do vortex motion. Generally, the electromagnetic stirrer is suitable for the riser with an inner diameter of less than 600 mm, and the magnetic induction intensity of the corresponding electromagnetic field is 0.1-0.2 Tes (Tesla).

[0024] Use method of the present invention to carry out vacuum refining process to 120 tons of ladle 5 in certain steel factory. The riser and downcomer 3 of the device have a diameter of 500 mm, and the vacuum chamber is pressed on the ladle so that the riser and the downcomer are immersed in the ladle, and the vacuum pump is started to evacuate. When the press...

Embodiment 2

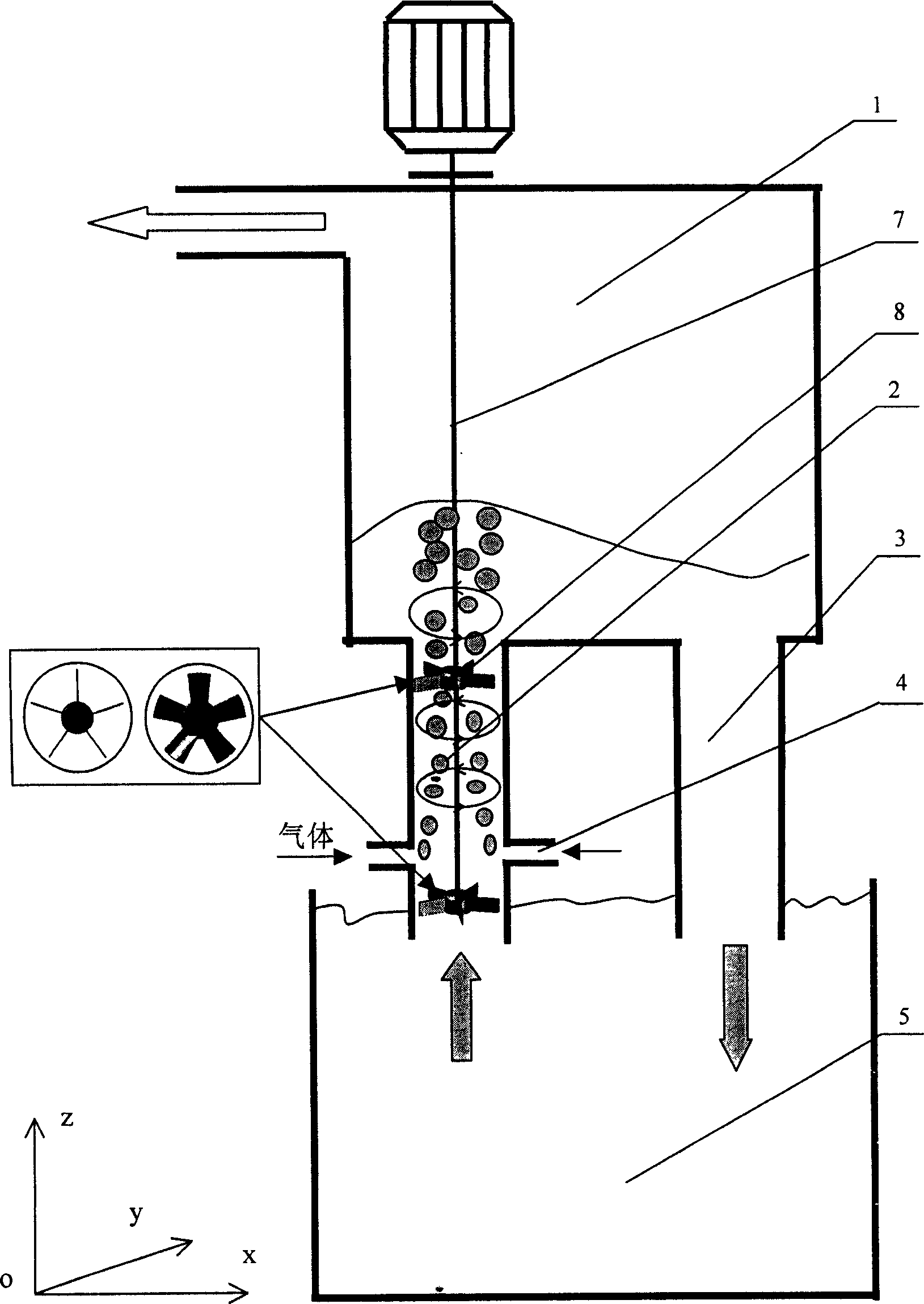

[0025] Embodiment 2: Improved circulation type molten steel vacuum refining method and device with mechanical agitator

[0026] The method and device are suitable for RH devices with an internal diameter of the riser tube of more than 600 mm. Adopt existing RH molten steel vacuum treatment device, according to such as image 3 The design shown is modified; a speed-regulating motor is placed on the upper cover of the vacuum chamber 1, and a rotating shaft 7 vertically inserted into the riser 2 is connected, and two impellers 8 are fixed on the shaft.

[0027] The impeller is detachable and is assembled from a wheel seat 9 and blades 10, such as Figure 5 shown. The mechanical stirrer of the present invention is equipped with three kinds of impellers. (1) if Figure 5 For the impeller with three blades shown in a, the plane of the blades is parallel to the busbar of the wheel seat, that is, the installation angle is 0°; (2) Figure 5 For the impeller with four blades shown ...

Embodiment 3

[0029] Embodiment 3: Improved circulation type molten steel vacuum refining method and device with composite stirrer

[0030] according to Figure 4 According to the design plan to transform the RH molten steel vacuum treatment device, a speed-regulating motor is installed on the cover of the vacuum chamber 1, and a rotating shaft 7 inserted vertically downward into the riser 2 is connected, and two impellers 8 are fixed on the shaft, each Five blades 10 are installed on the wheel seat 9 of the impeller, as Figure 5 As shown in c, the installation angle of the blade is 45°. A 0.1 t water-cooled electromagnetic winding is installed outside the riser tube.

[0031] When vacuum refining a 180 ton ladle, the inner diameter of the riser and downcomer is designed to be 600mm. Press the vacuum chamber onto the ladle 5, start the vacuum pump to evacuate, and when the pressure of the vacuum chamber drops to 1 torr, the molten steel begins to circulate in the ascending pipe and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com