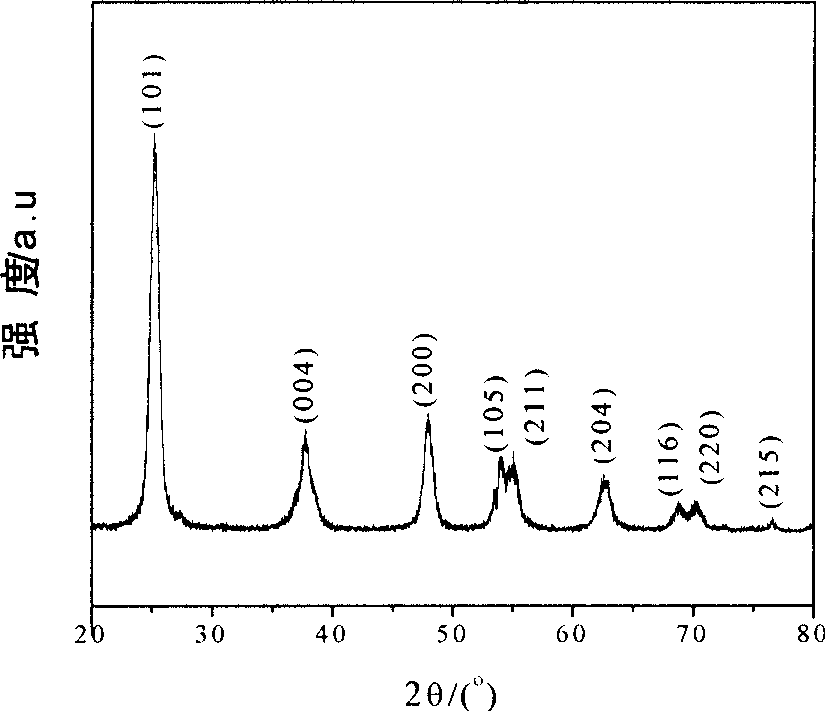

Method for preparation of unidimensional monocrystal titanium dioxide nano material

A technology of titanium dioxide and nanomaterials, applied in the field of nanomaterials, can solve the problems of complex experimental procedures, high costs, and high prices, and achieve the effects of simple preparation methods, high product yields, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

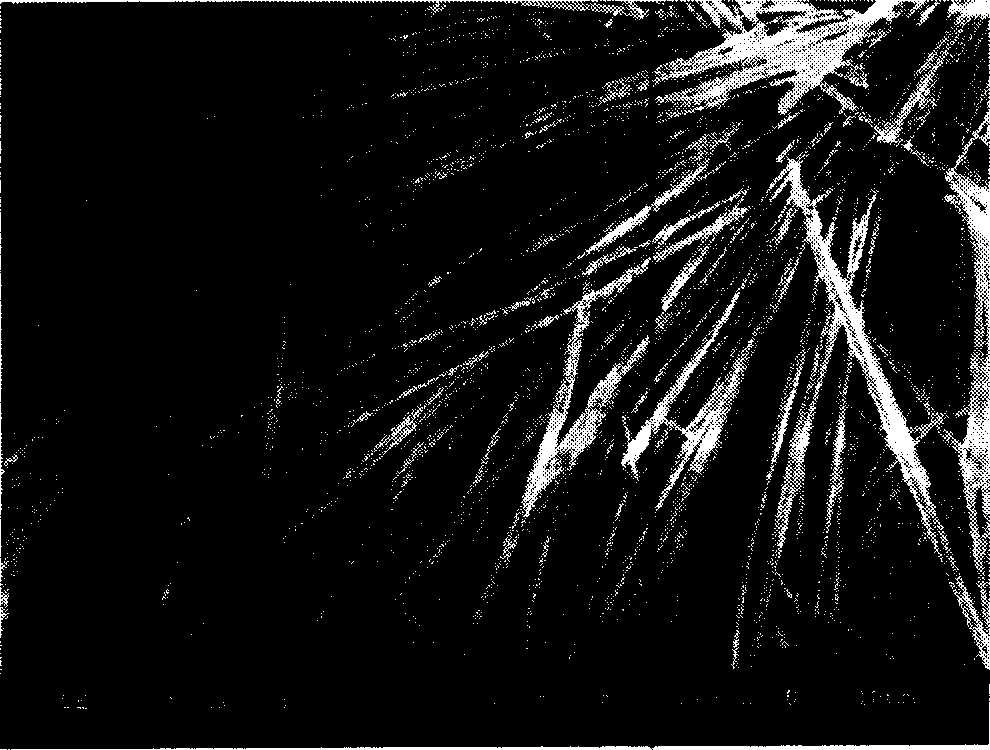

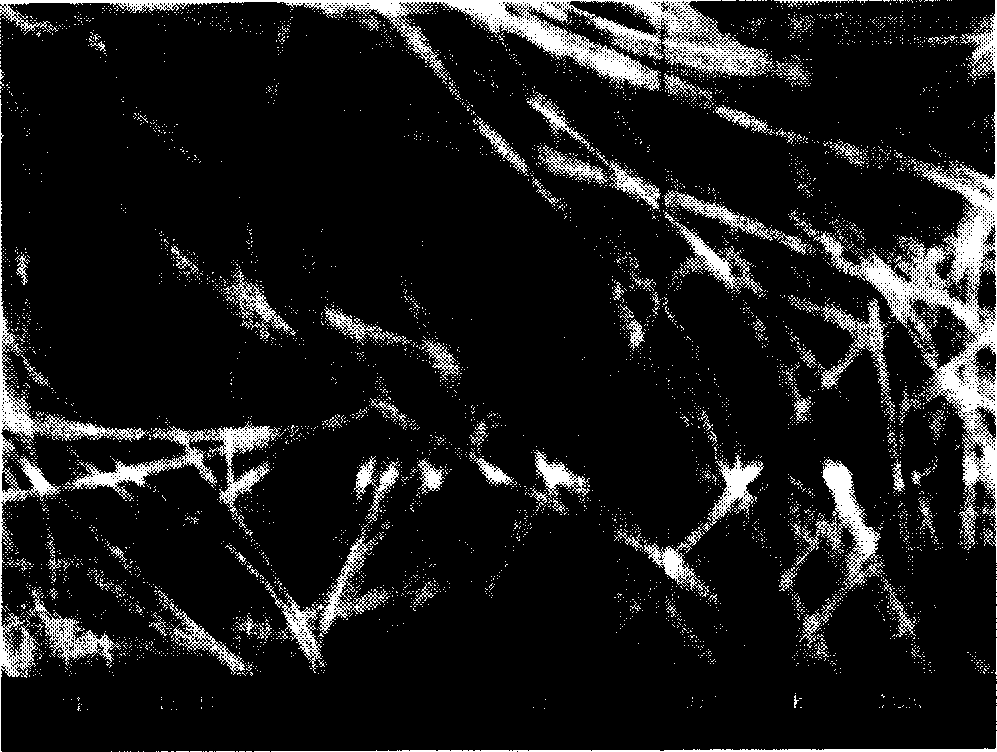

[0039] Take 25 parts by weight of commercial P25 powder and add it to 75 parts by weight of butanol, stir vigorously to obtain a uniformly dispersed mixture; under rapid stirring, add 70 parts by weight of 50 parts by weight of sodium hydroxide solution to 30 parts by weight of the above mixture The solution generated in 50 parts by weight of deionized water was continuously stirred for several minutes, then transferred into a polytetrafluoroethylene-lined autoclave, kept at 110° C. for 8 hours, and cooled naturally to room temperature. The supernatant was decanted, the lower precipitate was washed several times with deionized water and dilute sulfuric acid, centrifuged, and dried in an oven at 60° C. for 12 hours to obtain one-dimensional single-crystal titanium dioxide nanowires.

Embodiment 2

[0041] Take 1 part by weight of anatase titanium dioxide powder and add it to 99 parts by weight of dodecylamine, stir vigorously to obtain a uniformly dispersed mixture; add 82 parts by weight of 15 parts by weight of hydrogen to 18 parts by weight of the above mixture under rapid stirring The solution formed by dissolving sodium oxide in 85 parts by weight of deionized water was continuously stirred for several minutes, then transferred into a polytetrafluoroethylene-lined autoclave, kept at a constant temperature of 150°C for 2 hours, and cooled naturally to room temperature. The supernatant was decanted, the lower precipitate was washed several times with deionized water and dilute acetic acid, centrifuged, and dried in an oven at 120° C. for two days to obtain one-dimensional single-crystal titanium dioxide nanorods.

Embodiment 3

[0043] Take 15 parts by weight of commercial P25 powder and add it to 85 parts by weight of ethanol, and stir vigorously to obtain a uniformly dispersed mixture; under rapid stirring, add 50 parts by weight of 25 parts by weight of sodium hydroxide dissolved in 75 parts by weight to 50 parts by weight of the above mixture The solution generated in parts by weight of deionized water was continuously stirred for several minutes, then transferred into a polytetrafluoroethylene-lined autoclave, kept at a constant temperature of 200° C. for 16 hours, and cooled naturally to room temperature. The supernatant was decanted, the lower precipitate was washed several times with deionized water and dilute nitric acid, centrifuged, and dried at room temperature for three days to obtain a one-dimensional single crystal titanium dioxide nanowire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com