Polyhydroxy etherone and its preparation process

A technology of polyhydroxyetherketone and dihydroxybenzophenone is applied in the field of polyhydroxyetherketone and its preparation, and can solve the problems of slow crystallization rate, difficulty in dyeing, performance influence and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

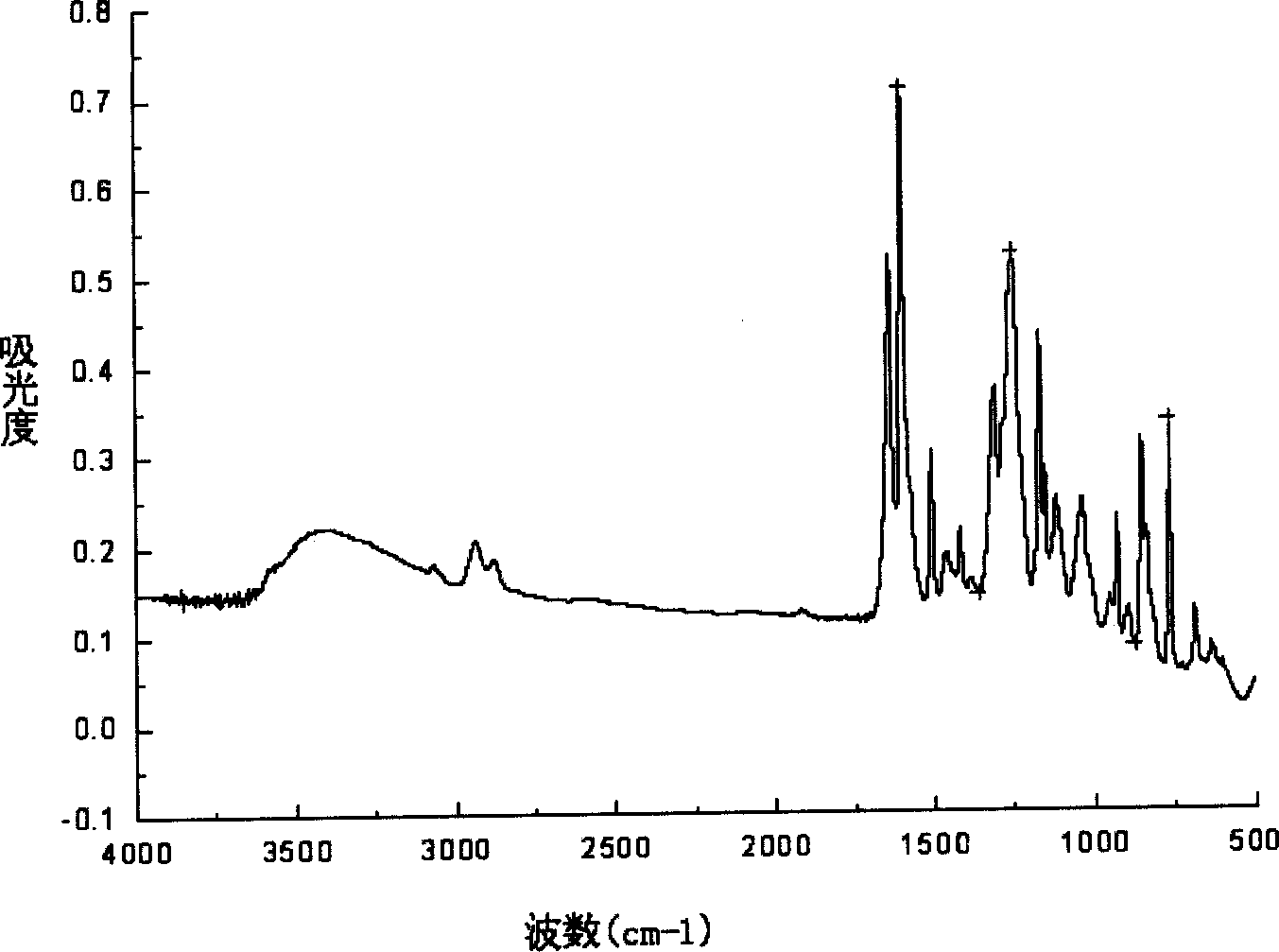

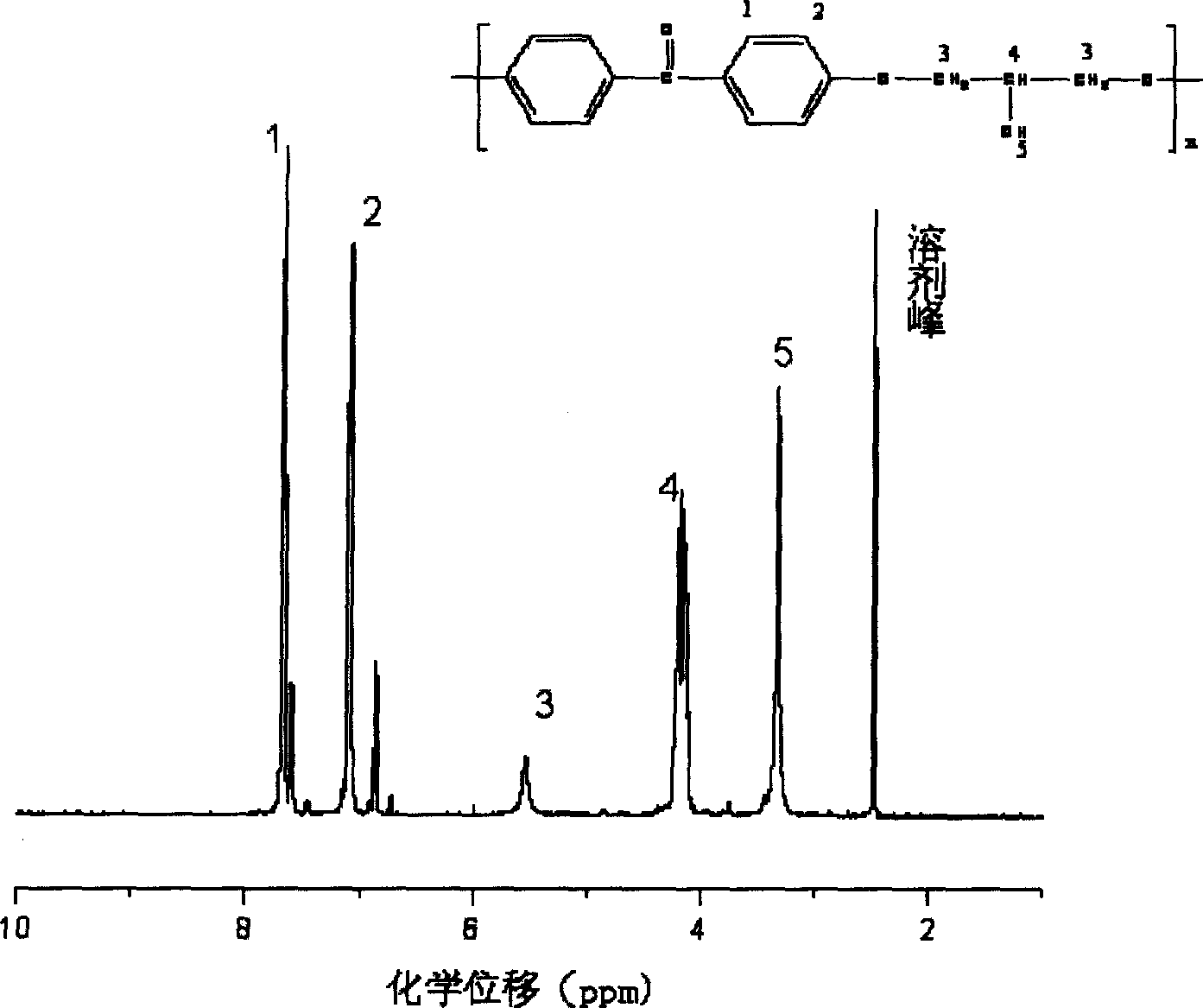

[0020] In a 500ml three-necked flask, add 0.1mol (21.4g) 4,4'-dihydroxybenzophenone and 0.1mol (9.25g) epichlorohydrin, then add 150ml dimethyl sulfoxide (DMSO), stir to make After 4,4'-dihydroxybenzophenone is completely dissolved, continue to stir for 3 hours and raise the temperature of the system to 60°C, then slowly add 10ml of 40wt% NaOH solution dropwise to promote the reaction and eliminate the hydrogen chloride generated during the reaction , after the sodium hydroxide solution was added dropwise, the system was heated up to 120°C, and the reaction was continued for 48 hours, and then the reaction liquid was poured into boiling water together to keep the water boiling to remove the reaction by-product NaCl and organic matter contained in the precipitate. Solvent until the precipitate is powdery, take out the powdery precipitate and put it in an oven to dry at 70°C to obtain 26.0 g of white or light yellow powdery polyhydroxy ether ketone with a yield of 95.9%. The mol...

Embodiment 2

[0032] Add 0.05mol (10.7g) 4,4'-dihydroxybenzophenone and 0.05mol (4.625g) epichlorohydrin into a 500ml three-necked flask, then add 120ml N, N'-dimethylformamide (DMF ), after stirring to completely dissolve 4,4'-dihydroxybenzophenone, continue to stir for 3 hours and raise the temperature of the system to 60°C, then slowly add 5ml of 40wt% NaOH solution dropwise to promote the reaction and eliminate the reaction After the hydrogen chloride and sodium hydroxide solution generated in the process are added dropwise, the temperature of the system is raised to 120°C, and the reaction is continued for 48 hours, and then the reaction solution is poured into boiling water together, and the water is kept boiling to remove the reaction mixture contained in the precipitate. By-product NaCl and organic solvent, until the precipitate is powdery, take out the powdery precipitate and put it in an oven and dry it at 70°C to obtain 12.8 grams of white or light yellow powder polyhydroxy ether ...

PUM

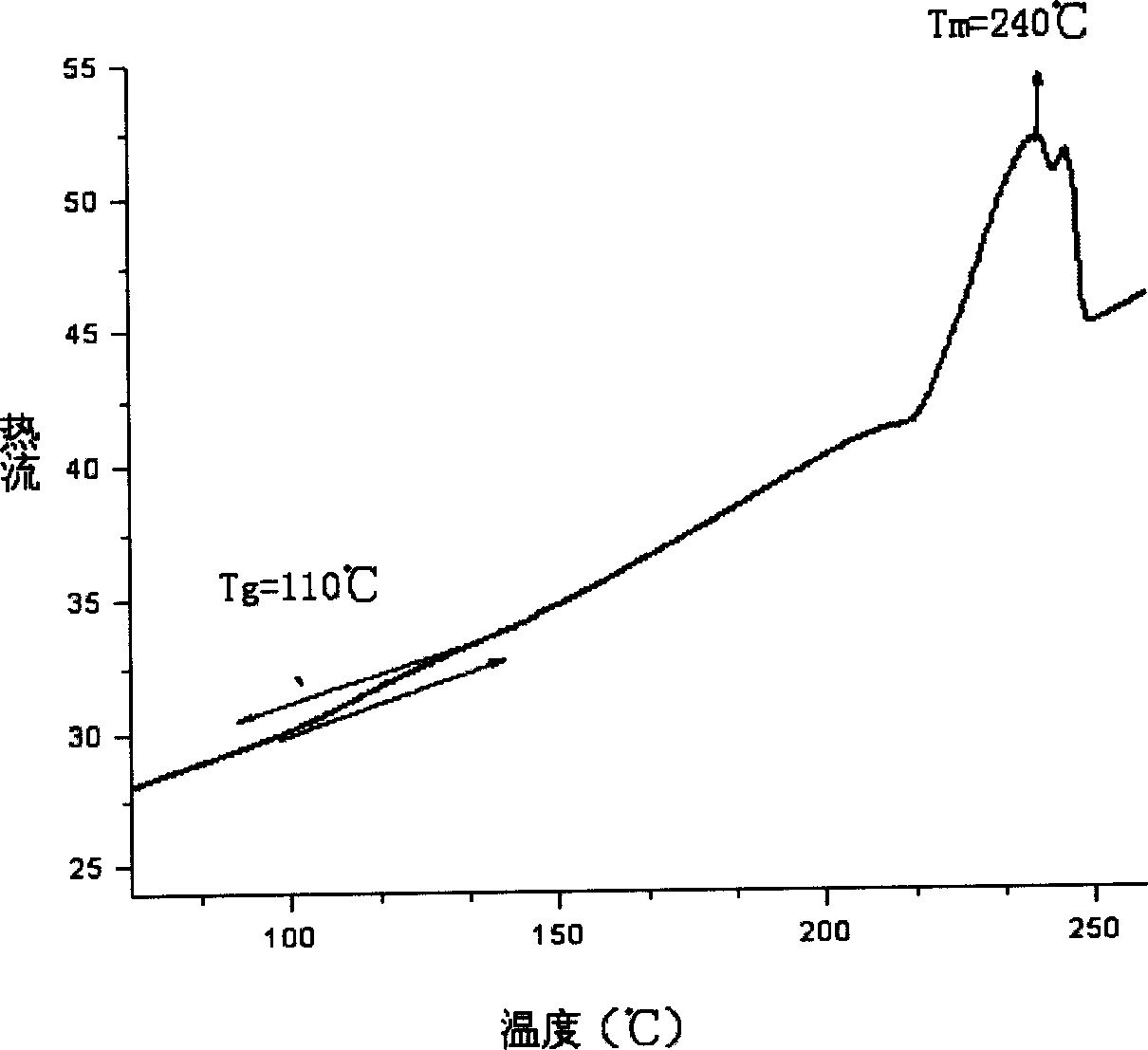

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com