Process for preparing tungstate nano film

A technology of nano-film and tungstate, applied in the field of preparation of tungstate nano-film, can solve the problems such as the preparation of tungstate nano-film which has not yet been seen, and achieve the effects of easy construction, convenient and concise product processing, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the first step, weigh 0.020mol lead acetate (analytical pure), and the tungsten source is 0.020mol sodium tungstate (analytical pure). Dissolve them in 50mL distilled water respectively to form two 0.4mol / L solutions.

[0024] Step 2: Add 28 mL of cyclohexane, 3 mL of Tween-80 and 1 mL of 0.4 mol / L metal salt solution prepared in the first step into the Erlenmeyer flask in sequence. Stir thoroughly at a speed of 3000 rpm, then add 1 mL of amyl alcohol each, and stir for about 15 minutes until the reversed micellar solution becomes clear to obtain a metal salt micellar solution. Using the tungsten source solution prepared in the first step instead of the metal salt solution, the same method was used to obtain the tungsten source micellar solution. Then the prepared two micellar solutions were mixed rapidly, and stirred at room temperature for 5 minutes to make them evenly mixed. After 12 hours of reaction, acetone was added to break the emulsion. Use a centrifuge t...

Embodiment 2

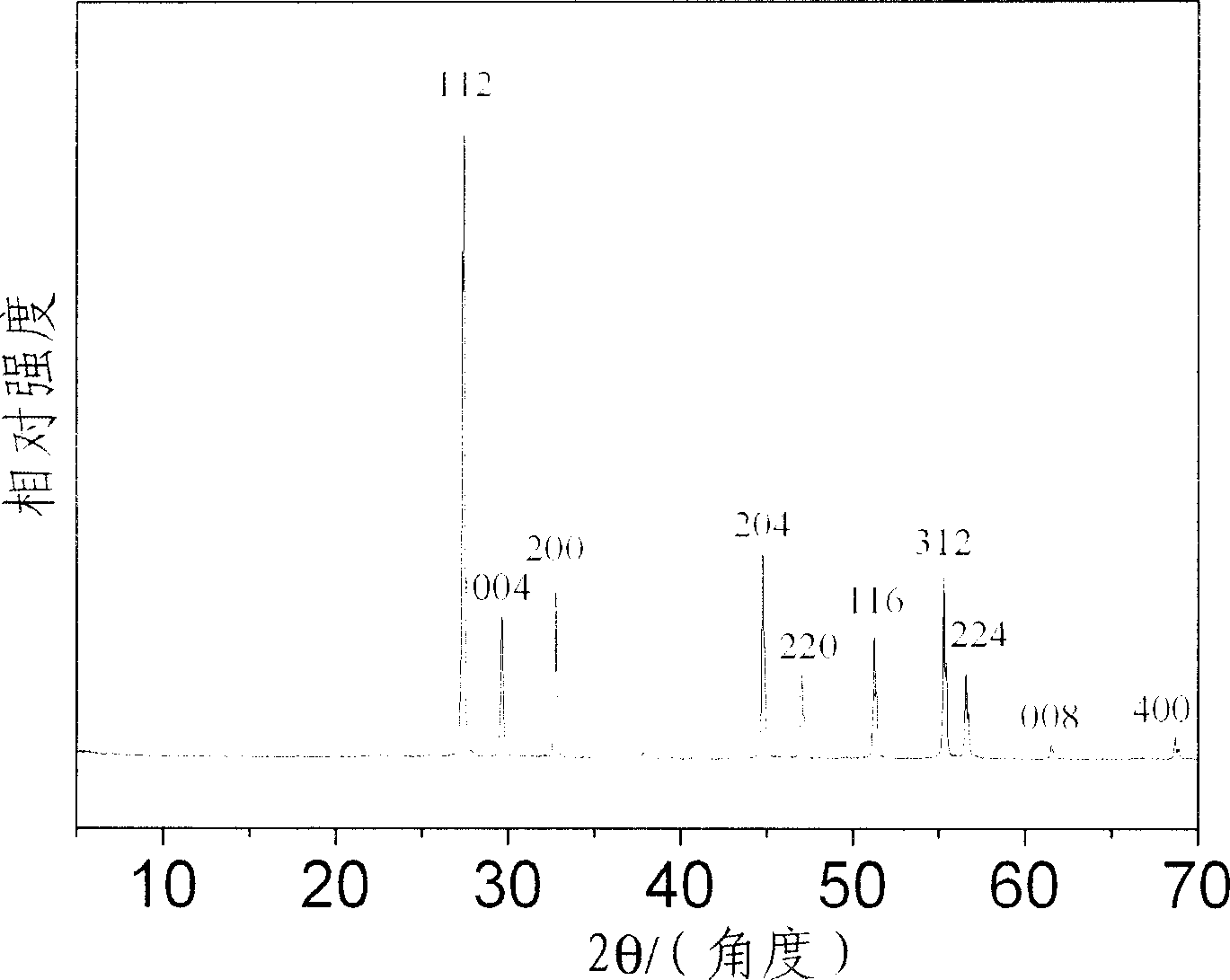

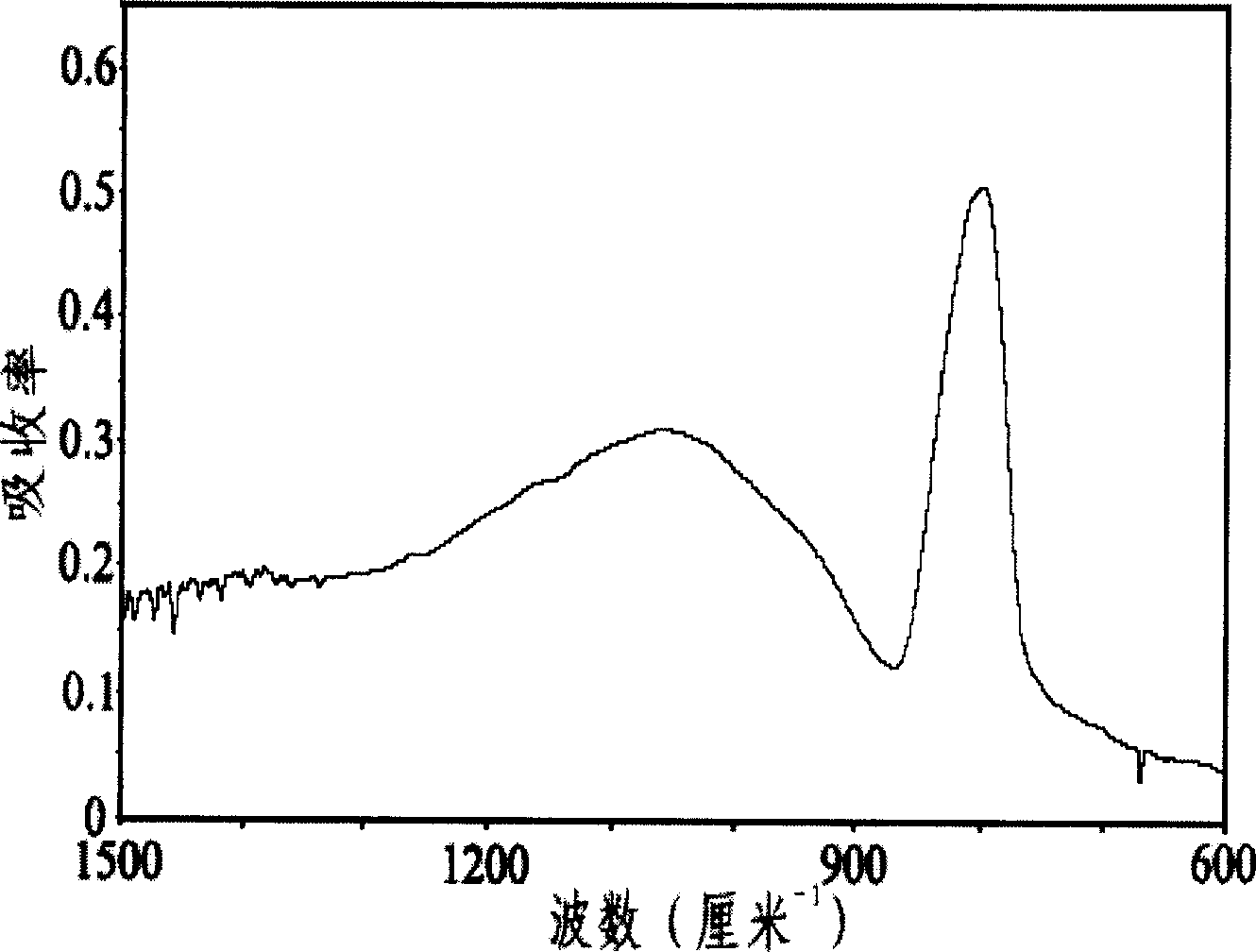

[0029] Comparative example without adding collodion. Other conditions and steps are exactly the same as in Example 1, and the product obtained is peanut-shaped PbWO 4 nano film. Scanning electron microscopy (SEM) observations of the product showed that the prepared PbWO 4 The dispersion of the nano film is very uneven, the density is low, and its shape is peanut-like, about 300nm long and 180nm in diameter. The PbWO 4 The nano-film is tetragonal tungstenite, and its luminescence performance is obviously inferior to that of PbWO 4 nano film.

Embodiment 3

[0031] Replace 0.020mol lead acetate with 0.020mol barium acetate, other conditions and steps are exactly the same as in Example 1, the product obtained is a highly dense rod-shaped barium tungstate nanofilm, the diameter of the nanorod is 50nm, and the length is about 180nm. And the length and thickness of the rods are relatively uniform. The rod-shaped nano film is tetragonal tungstenite, the product has high purity, good crystallinity and optical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com