Method and equipment of integrated reaction and separation for preparing chitosan oligosaccharide

A separation method and technology of chitosan oligosaccharides, which are applied in the field of integrated reaction separation methods and devices for the preparation of chitosan oligosaccharides, can solve problems such as difficulty in obtaining active oligosaccharides, difficulty in obtaining specific enzymes, consumption of chemical oxidants, etc., and achieve economical Good performance, easy integration, high extraction purity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

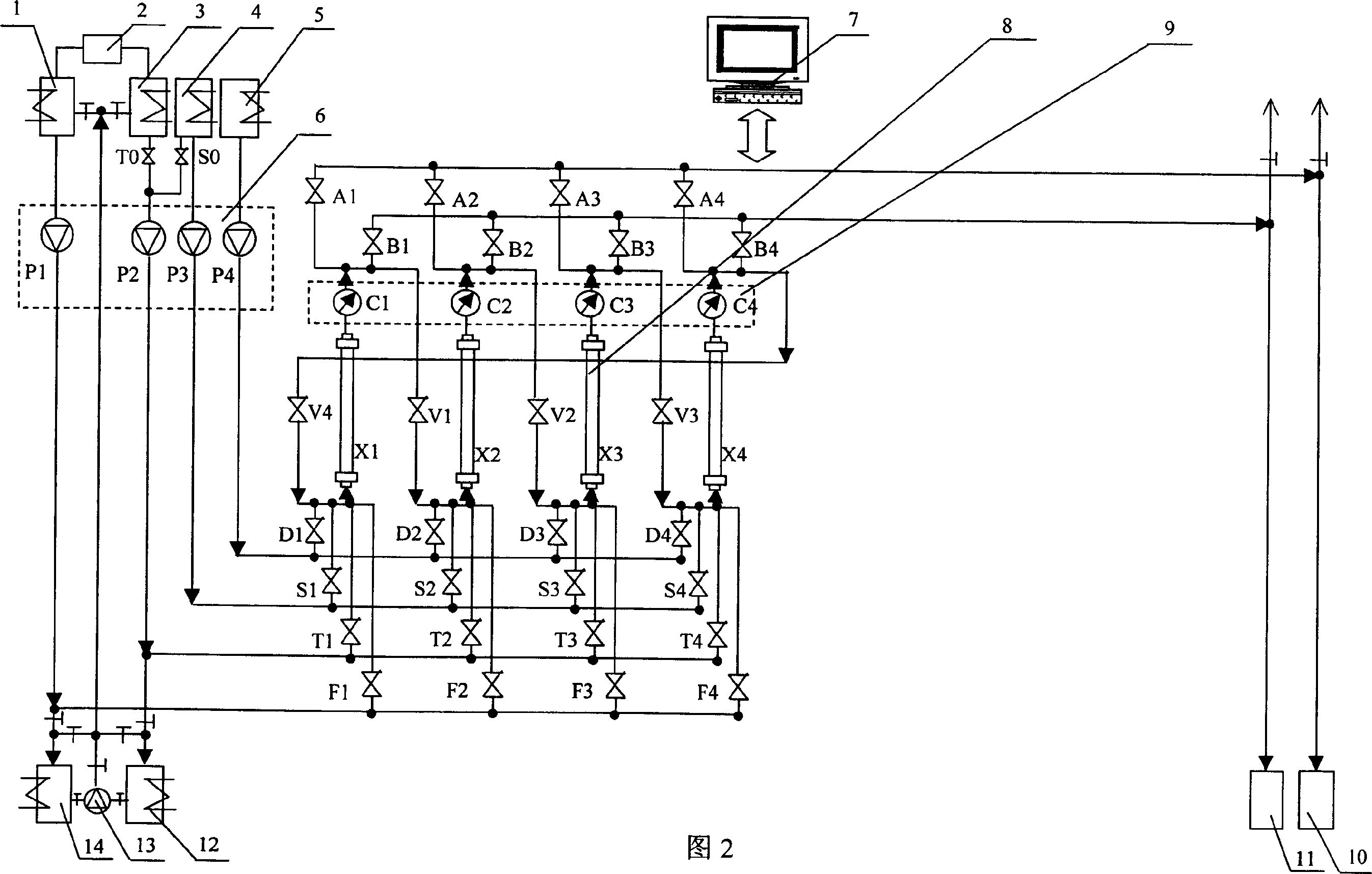

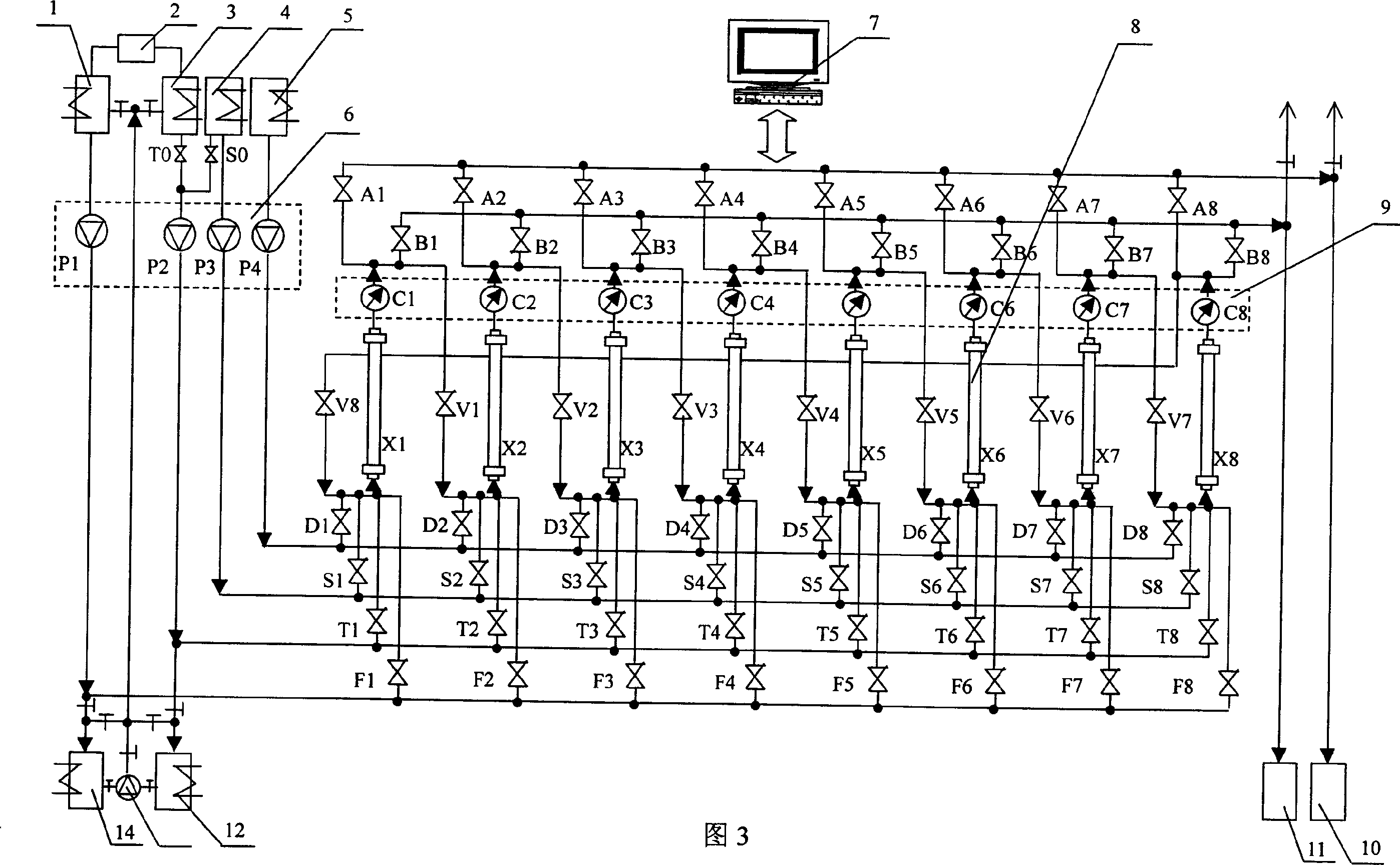

[0024] In the electrochemical degradation reaction part shown in Fig. 1, Fig. 2 and Fig. 3, the output voltage of the DC power supply 2 is 0-12V, and the current is 0-20A.

[0025] Adopt electrochemical reactor 1 to carry out chitosan degradation reaction, its structural type is as follows Figure 4As shown, the box-type housing 15 in the figure is made of non-metallic materials, and the electrode plate 16 is composed of 4 artificial graphite plates, with a width of 380mm, a height of 180mm, and an average thickness of 18mm. They are arranged in parallel to form a bipolar three-section series connection. Advanced diaphragmless electrochemical reactor, the average distance between electrodes is 20mm, and the single electrode area is 6.8dm 2 , Effective reaction solution volume 5L.

[0026] The concentration of chitosan input is 10g / L, the concentration of NaCl is 20g / L, the pH value of the solution is 1~3, the reaction temperature is 40~50℃, and the current density is 2~3A / dm ...

Embodiment 2

[0030] The degradation reaction apparatus used is the same as Example 1.

[0031] The concentration of chitosan input is 20g / L, the concentration of NaCl is 20g / L, the pH value of the solution is 1-3, the reaction temperature is 50-60°C, and the current density is 2-3A / dm 2 .

[0032] Reaction control method is the same as example 1, still taking 90% of viscosity drop as control target.

[0033] Finally, the reaction time was 130min, and the reaction completion liquid was measured, and the generation rate of chitosan oligosaccharide was 84.5%, and the reaction completion liquid was light yellow-green.

Embodiment 3

[0035] The degradation reaction apparatus used is the same as Example 1.

[0036] The concentration of chitosan input is 20g / L, the concentration of NaCl is 20g / L, the pH value of the solution is 1~3, the reaction temperature is 60~70℃, and the current density is 2~3A / dm 2 .

[0037] The reaction control method is the same as Example 1. Still take the viscosity drop of 90% as the control target.

[0038] Finally, the reaction time was 120min, and the reaction completion liquid was measured, and the generation rate of chitosan oligosaccharide was 81.7%, and the reaction completion liquid was light brown. It shows that the side reaction on the surface of the anode increases, and the generation rate of chitosan oligosaccharides decreases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com