Epoxy sodium succinate and its process for preparing polymer

A technology of sodium epoxysuccinate and polymer, applied in the direction of flocculation/sedimentation water/sewage treatment, organic chemistry, etc., can solve the problems of low calcium ion content, inconvenient direct application, complicated separation process, etc., and achieve good biodegradability , Reduce the generation of by-products, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

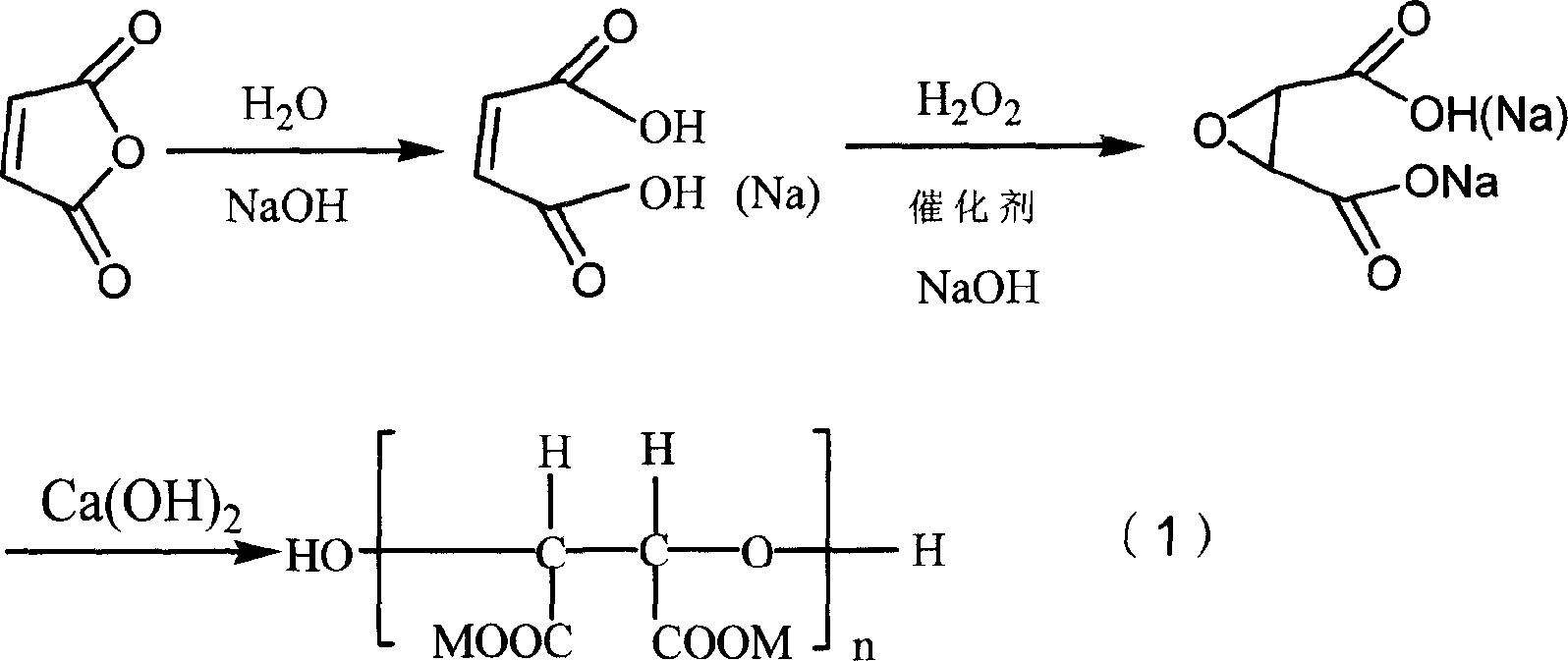

Method used

Image

Examples

Embodiment 1

[0016] Add maleic anhydride and water into the three-necked bottle at a molar ratio of 1:8~10, stir to make it completely dissolve in water, add an appropriate amount of sodium hydroxide solution dropwise, pay attention to controlling the dropping speed, and drop it within 20~30 minutes finished adding. Heating, when the solution temperature reaches 55°C, add catalyst according to 0.01-0.1 of the amount of maleic anhydride, then continuously add 30% hydrogen peroxide which is 1.0-1.3 times of the amount of maleic anhydride, and drop Sodium hydroxide keeps the pH value of the solution between 5 and 7, and the dropwise addition is completed within 30 to 40 minutes. After the dropwise addition is completed, it is heated to 65 to 75° C. and reacted at this temperature for 1 to 1.5 hours. After the reaction, the solution was cooled to room temperature, and acetone was added, and sodium epoxysuccinate precipitated out in white, and then washed 2 to 3 times to obtain sodium epoxysucc...

Embodiment 2

[0025] Weigh 49 g of maleic anhydride into a three-neck flask, stir to make it completely dissolve in water, at this time the pH of the solution is between 2 and 3, and the solution is colorless. Add 80g of 50% sodium hydroxide solution dropwise to the above solution with a dropper. At this time, the reaction is strongly exothermic, and the color of the solution changes from transparent to white, so that the temperature of the solution does not exceed 55°C. The sodium hydroxide solution is added dropwise within 15 minutes. . Weigh 1.7g of the catalyst (the molar ratio of sodium tungstate to ammonium vanadate is 2:1), and add it into the solution. Measure 65ml of 30% hydrogen peroxide, and slowly add it dropwise to the above solution within 20 minutes. While adding the hydrogen peroxide solution dropwise, use a pipette to add 50% sodium hydroxide dropwise to adjust the pH value to about 7. The color of the solution is from white to off-white. The solution was heated up to 70...

Embodiment 3

[0027] The 0.5mol sodium epoxysuccinate prepared in Example 2 was dissolved in 87.9ml of deionized water, stirred to make it completely dissolved, then added 1.85g of initiator calcium hydroxide in batches, and heated to 90°C with an oil bath. ~100°C, react at this temperature for 3~4 hours to obtain sodium polycyclosuccinate. After analysis, the composition distribution of the polymer is: n=1~2 accounts for 8%, n=3~6 accounts for 25%, and n=3~6 accounts for 25%. >6 accounted for 67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com