Tropisetron hydrochloride oral disintegration tablet preparation and its preparing method

A technology for tropisetron hydrochloride and oral disintegrating tablets, which is applied in the directions of pill delivery, digestive system, drug combination, etc., can solve the problems of complex process and high cost, and achieve the effects of simple process, low cost and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

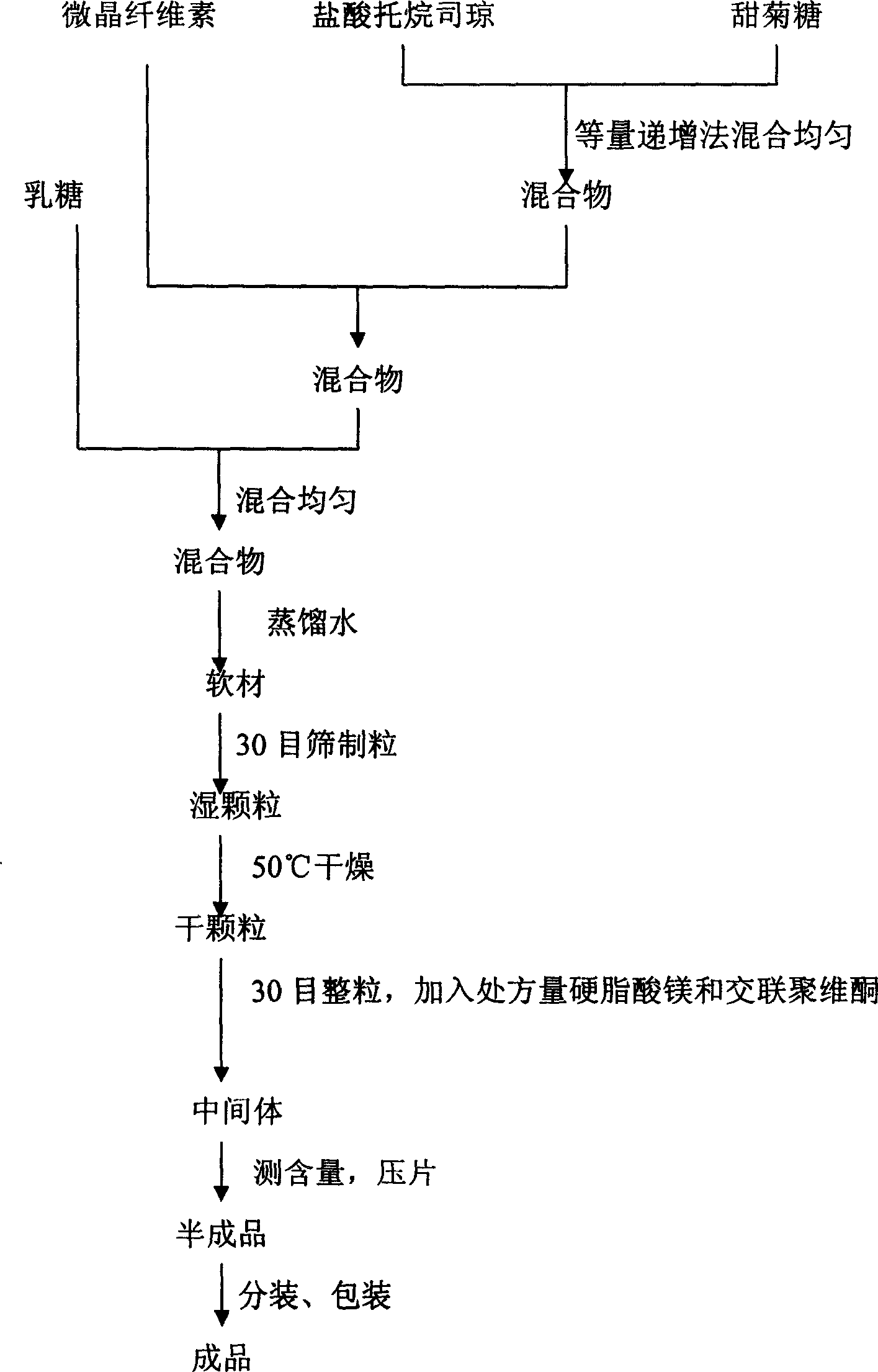

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Preparation of Tropisetron Hydrochloride Orally Disintegrating Tablets (1000 tablets)

[0014] ① Pass 30g of tropisetron hydrochloride through a 100-mesh sieve, pass through a 100-mesh sieve for the auxiliary materials respectively, put the auxiliary materials in an oven at 50°C for 3 hours, and set aside.

[0015] ② Mix 20g of mannitol with tropisetron hydrochloride.

[0016] ③ Another 30g of lactose is mixed with the mixture in step ② according to the method of equal increment.

[0017] ④ Use distilled water to make soft material from the above mixture, use a 30-mesh sieve to make granules, and dry the wet granules at 40°C for 30 minutes. The obtained dry granules were sized through a 30-mesh sieve, and then 0.3 g of magnesium stearate, 1.5 g of microcrystalline cellulose, and 4 g of crospovidone were added and mixed uniformly.

[0018] ⑤ determination of intermediate content.

[0019] ⑥Adopt 6.0-8.5mm shallow arc punched tablets, control the tablet w...

Embodiment 2

[0022] Embodiment 2: Preparation of Tropisetron Hydrochloride Orally Disintegrating Tablets (1000 tablets)

[0023] ① Pass 30g of tropisetron hydrochloride through a 100-mesh sieve, pass through a 100-mesh sieve for the auxiliary materials respectively, put the auxiliary materials in an oven at 50°C for 3 hours, and set aside.

[0024] ② Mix 30g of mannitol with tropisetron hydrochloride.

[0025] ③ Another 20g of lactose is mixed with the mixture in step ② according to the method of equal increase.

[0026] ④ Use distilled water to make soft material from the above mixture, use a 30-mesh sieve to make granules, and dry the wet granules at 40°C for 30 minutes. The obtained dry granules were sized through a 30-mesh sieve, and then 0.15 g of magnesium stearate, 5.0 g of microcrystalline cellulose, and 8 g of crospovidone were added and mixed uniformly.

[0027] ⑤ determination of intermediate content.

[0028] ⑥Adopt 6.0-8.5mm shallow arc punched tablets, control the tablet w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com