Ceramic hollow fiber membrane reactor for making oxygen by air separation, and its preparing method and use

A fiber membrane reactor and fiber membrane technology are applied in separation methods, chemical instruments and methods, and evaporators heated by serpentine tubes. Difficult connection and other problems, to achieve broad commercial application prospects, excellent oxygen permeability, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

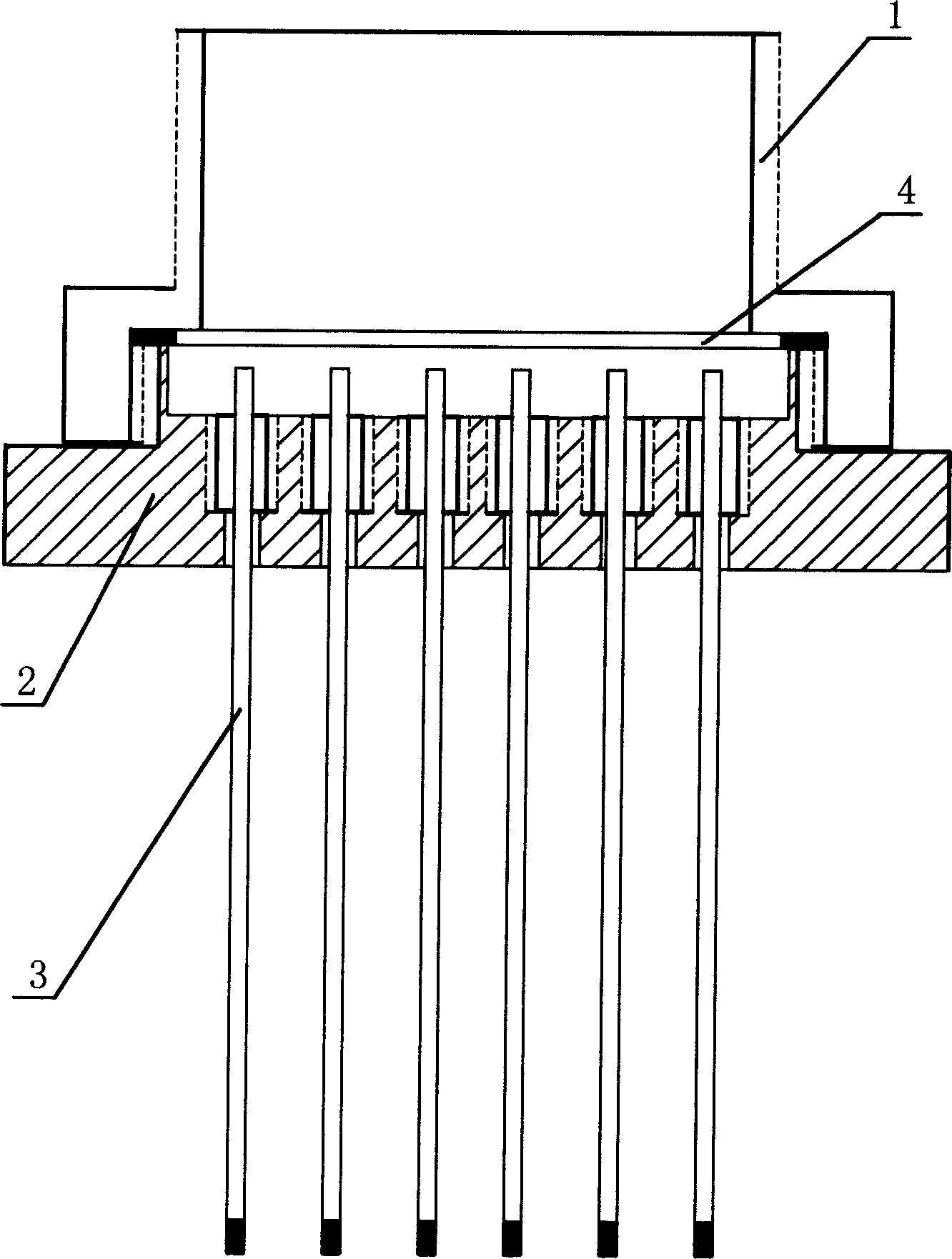

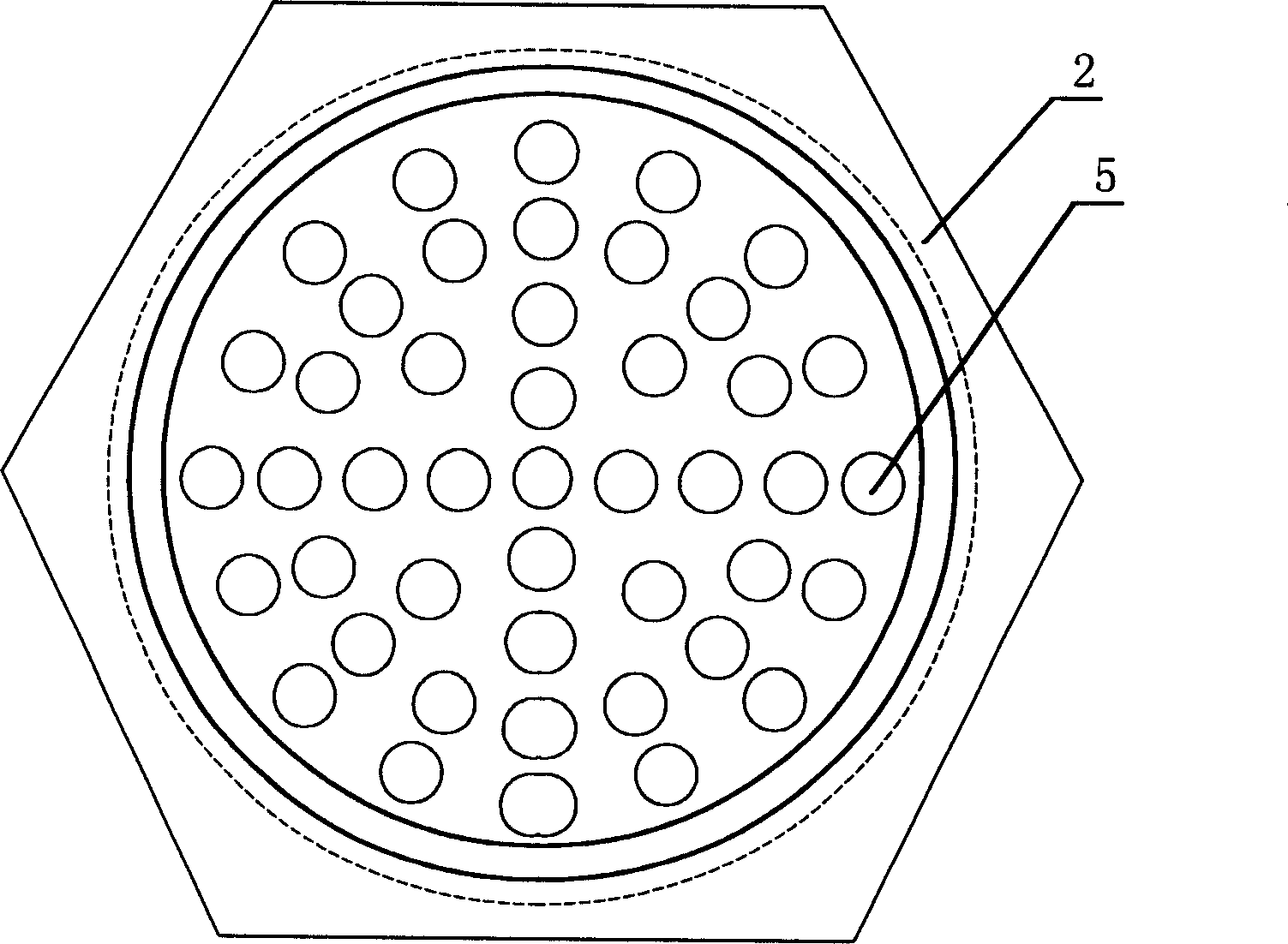

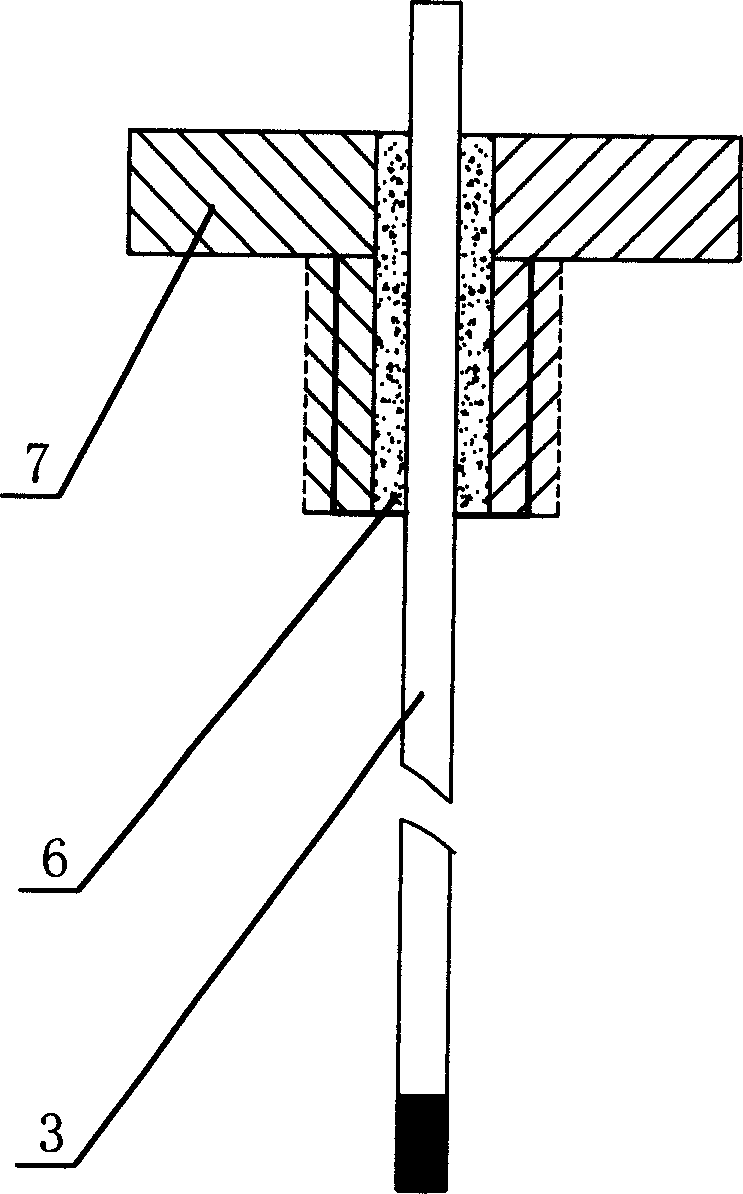

[0085] La 0.6x Sr 0.4 co 0.2 Fe 0.8 o 3-α (abbreviated as LSCF, produced by sol-gel method, average particle size 60nm) preparation of hollow fiber membrane and membrane tube reactor

[0086] The steps are: preparation of oxygen ion-electron mixed conductive ceramic electrolyte material, preparation of asymmetric hollow fiber ceramic membrane, hollow fiber membrane sintering, assembly of hollow fiber ceramic membrane reactor;

[0087] The process of preparing oxygen ion-electron mixed conductive ceramic electrolyte material is as follows:

[0088] (1) Preparation of organic polymer solution by water-soluble polymer sol method

[0089] Dissolve the organic polymer in an organic solvent, add additives and dissolve together to form an organic polymer solution; the dissolution temperature is 20-30°C; the organic polymer is polysulfone or polysulfone ether; the solvent is ethanol or N-N-dimethylacetyl ammonia.

[0090] The weight percentage is composed of: organic polymer: s...

Embodiment 2

[0107] In the process of preparing oxygen ion-electron mixed conductive ceramic electrolyte material, the melting temperature is 70-80°C; the organic polymer is polyester or cellulose acetate; the solvent is N-methylpyrrolidone or N,N-dimethylformaldehyde Amide; the additive is poly

[0108] Acrylic acid and its salt; the percentage by weight is composed of: organic polymer: solvent: additive = 10%: 87%: 3%. In the organic polymer solution, the weight ratio of the added oxygen ion-submixed conductive ceramic electrolyte material is: electrolyte material: organic polymer=5:1;

[0109] Oxygen ion-electron mixed conductive ceramic electrolyte material selection sol-gel method prepared 0% titanium-doped yttrium-stabilized zirconia (YSZ, Yttrium Stabilized Zirconium), with an average particle size of 60nm;

[0110] The film-making mold is a hollow fiber spinneret made of aluminum; the condensate is a mixed solution of water and methanol or ethanol in any proportion.

[0111] The ...

Embodiment 3

[0113] In the process of preparing oxygen ion-electron mixed conductive ceramic electrolyte material, the melting temperature is 40-50°C; the organic polymer is selected from cellulose acetate or polyester; the solvent is selected from dimethyl sulfoxide or trimethyl phosphate; the additive is selected from Polymethacrylic acid and its salt; the percentage by weight is: organic polymer: solvent: additive = 25%: 73%: 2%.

[0114] In the organic polymer solution, the weight ratio of the added oxygen ion--electron mixed conduction ceramic electrolyte material is: electrolyte material: organic polymer=5:1;

[0115] Oxygen ion-electron mixed conductive ceramic electrolyte material selection sol-gel method prepared 12% praseodymium-doped yttrium-stabilized zirconia (YSZ, Yttrium Stabilized Zirconium), with an average particle size of 60nm;

[0116] The film-making mold is a hollow fiber spinneret made of aluminum; the condensate is a mixed solution of water and propanol or ethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com