Substrate bonding method buried with Bragg reflector having high reflectivity

A Bragg reflector, high reflectivity technology, applied in the structure of optical resonator cavity, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problem of mirror surface roughness and cannot be directly bonded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

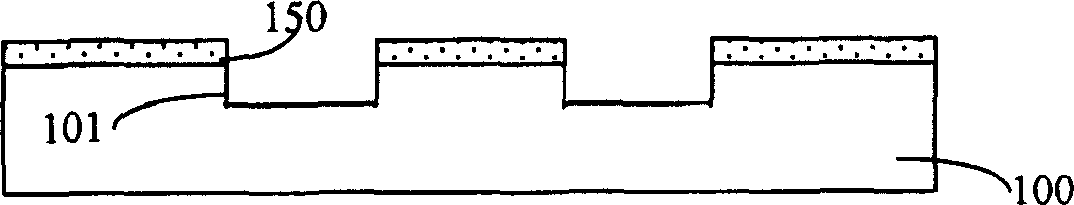

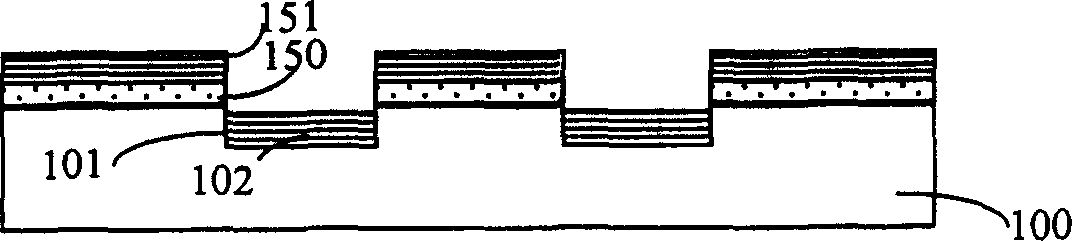

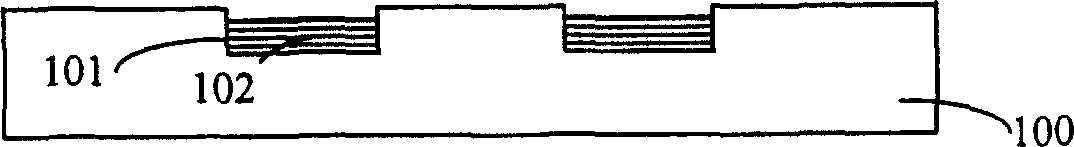

[0024] see Figure 1A ~ Figure 1E , this embodiment discloses a schematic diagram of a process for manufacturing a high-reflectivity substrate buried with a high-reflectivity Bragg reflector using the substrate bonding technology disclosed in the present invention. Its process steps include:

[0025] a) mask photolithography on the first substrate 100, etch out the groove 101, and keep the photoresist 150 ( Figure 1A middle);

[0026] b) growing a high-reflectivity Bragg mirror 102 in the trench 101 ( Figure 1B middle);

[0027] c) The Bragg reflector 151 and the photoresist 150 outside the trench 101 are stripped off by stripping with glue, and the reflector 102 in the trench is retained ( Figure 1C middle);

[0028] d) performing a chemical cleaning treatment on the first substrate 100 and the second substrate 110, and then bonding them together at room temperature for pre-bonding ( Figure 1D middle);

[0029] e) Carry out high temperature thermal annealing treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com