Heat isolating composite film and its prepn and use

A composite film and function technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of low performance, thick insulation film material, single function, etc. The effect of contact heat conduction and reasonable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

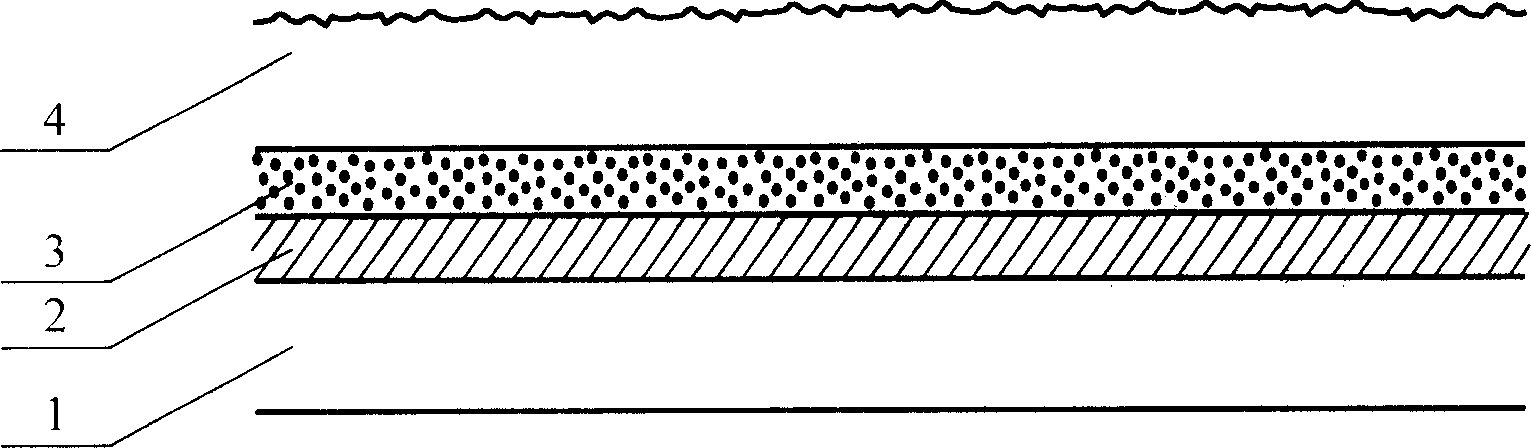

[0036] The heat-insulating composite film of the present invention uses a calendered polyester film of 12 μm, on which a dense aluminum layer with a thickness of 38nm to 42nm is evaporated and coated, and then the evaporated coating of larger particles of aluminum metal particles in an aerobic environment is used. The thickness is 28nm-32nm. Finally, a 10μm polyester calendered film with a melting temperature slightly lower than that of the base film is used to calender and compound the base film of the metal coating to form a sandwich structure composite film with a polymer sandwiched by a metal layer. The structure is shown in the attached figure 1 . The thickness of the formed composite film is only 21.8-21.9 μm, and the thermal conductivity is relatively low compared to the two-layer composite film (polyester film 24 μm + aluminum layer 40nm-45nm) and the three-layer composite aluminum film (polyester film 12 μm + aluminum layer 38nm) ~ 42nm + polyester film 12μm) has obvi...

Embodiment 2

[0041] Using the same base film and metal coating as in Example 1, and covered with a modified polyester film, the melting temperature of the film is 200-210 ° C, and the thickness is 6-7 μm. film, it is easier to carry out thermal bonding processing between films. The measured overall average thickness is 18.3-18.4 μm, and the measured thermal conductivity is compared with that of Example 1 as shown in Table 3. Obviously, the thermal insulation of the coated film is better, the reason is that the surface of the film is rougher and the structure is looser, especially when the multi-layer composite film is combined.

[0042] Composite film

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com