Bonded substrate, surface acoustic wave chip, and surface acoustic wave device

A surface acoustic wave and substrate technology, which is applied in the direction of device material selection, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problems of reduced device qualification rate and reduced joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described below with reference to the drawings.

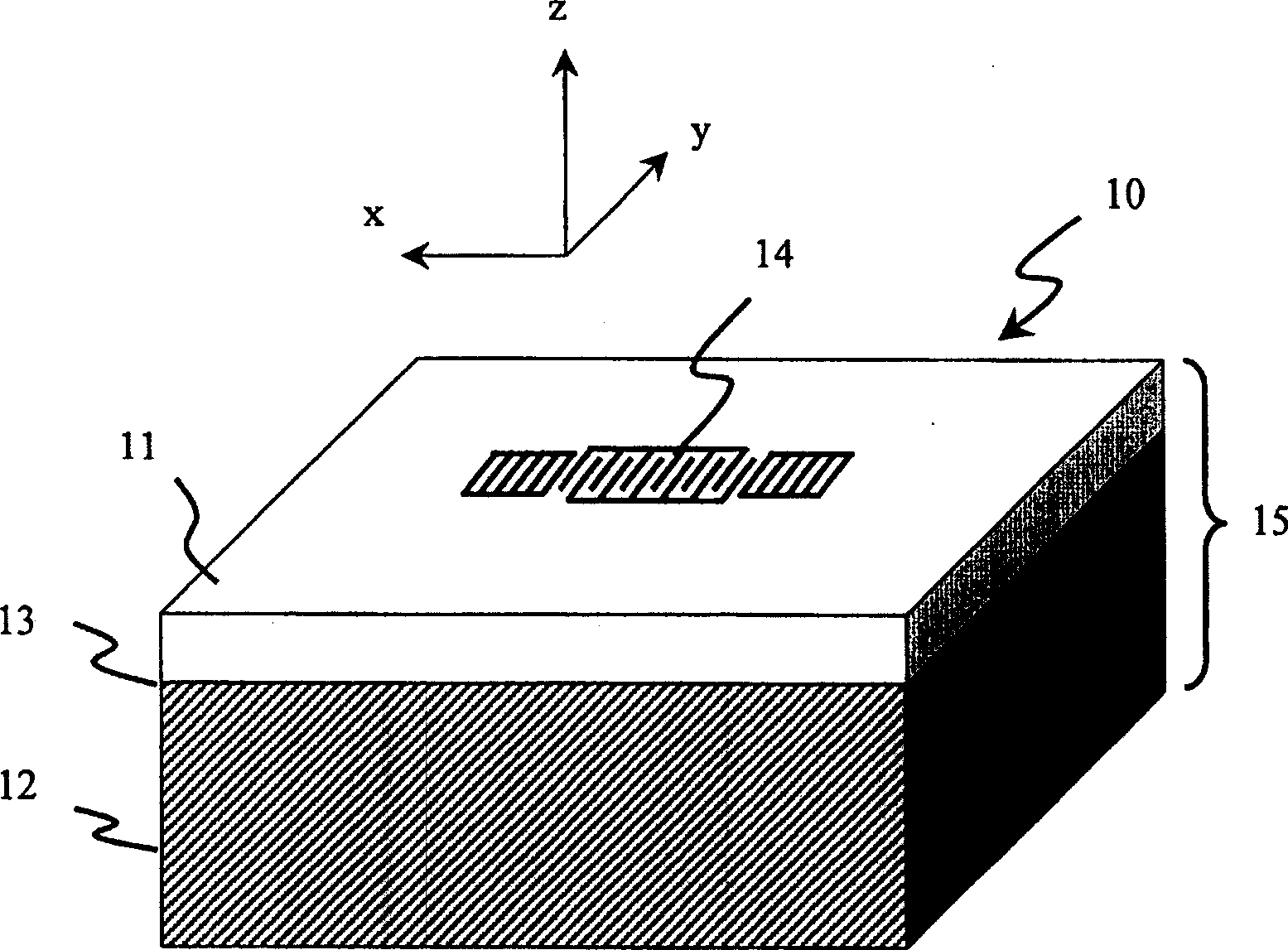

[0022] figure 1 is a perspective view of a SAW chip manufactured using the bonded substrate according to the present invention. The SAW chip 10 includes a bonding substrate 15 . The bonding substrate 15 includes a piezoelectric substrate 11, a supporting substrate 12, and a bonding interface 13 in an amorphous state. The piezoelectric substrate 11 and the support substrate 12 are bonded via a bonding interface 13 . The SAW resonator 14 is placed on the main surface of the piezoelectric substrate 11 so that the SAW propagates in the X direction.

[0023] The piezoelectric substrate 11 employs a single crystal LT substrate (42° Y-cut X-propagation LT substrate) that is rotated at 42 degrees around the X axis as the propagation direction and Y-cut. The single crystal LT substrate has a thickness of 40 μm. The linear expansion coefficient of the SAW propagation direction X of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com