Sealed dust-proof temperature control cabinet for computers

A computer and chassis technology, which is applied in the field of sealed dustproof and temperature-controlled computer chassis, can solve problems such as burning out parts, affecting the stable operation of the whole machine, and offsetting subjective efforts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

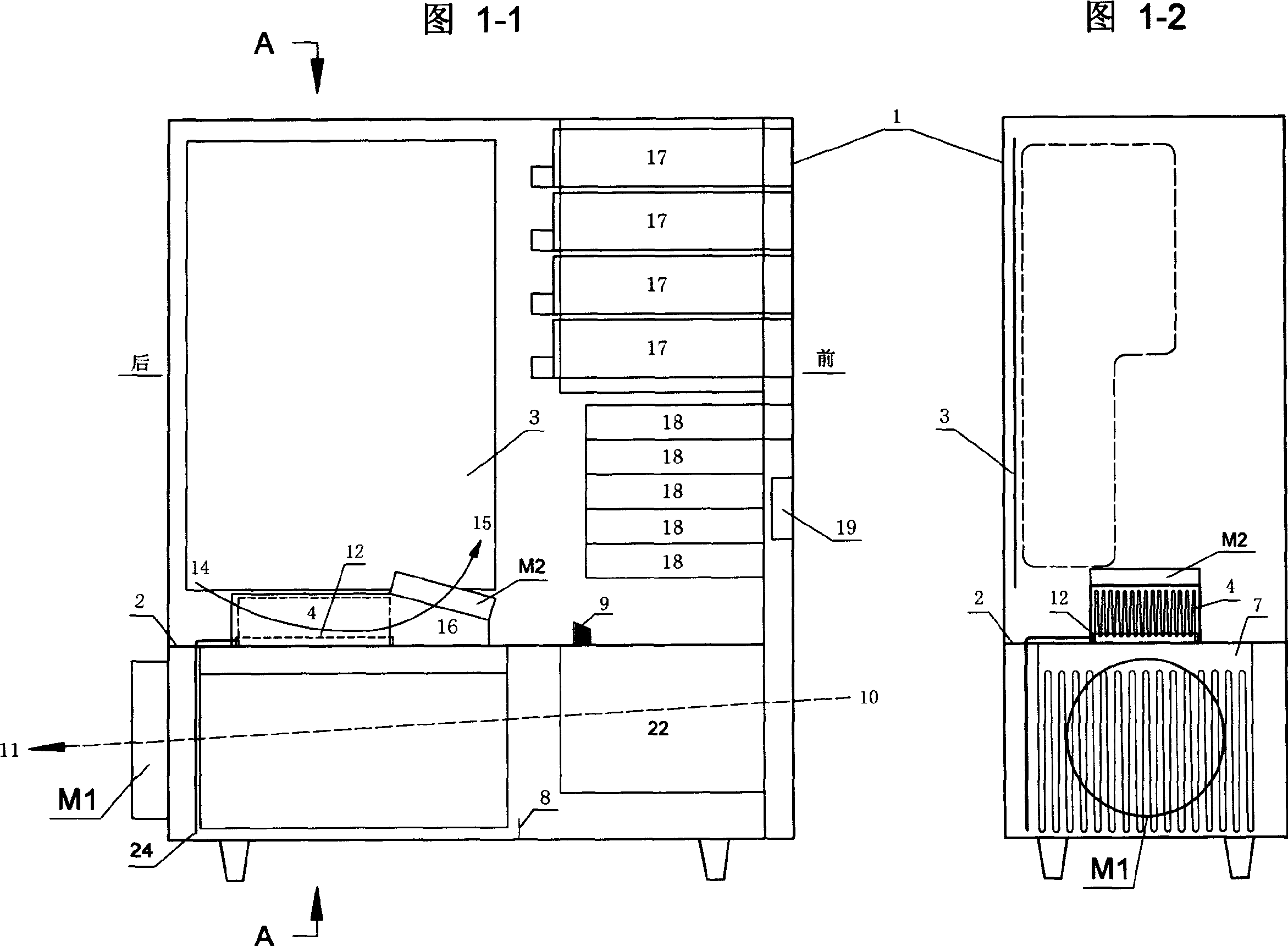

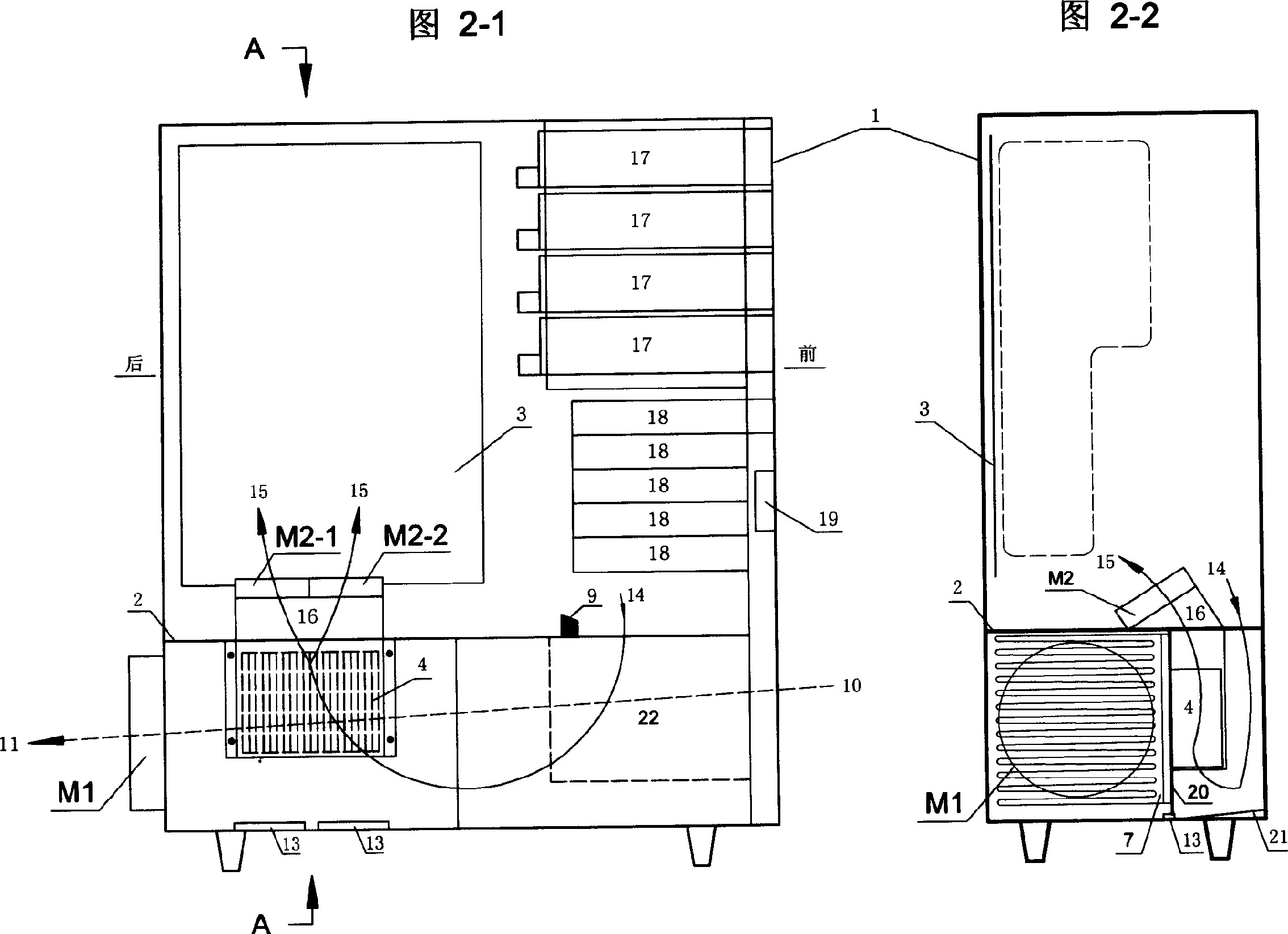

[0048] figure 1 , figure 2 It is a schematic diagram of the method to realize this example. in, figure 1 It is a schematic diagram when the cooling plate is installed horizontally, figure 2 It is a schematic diagram when the cooling plate is installed vertically. The characteristic of this example is that the cold stack assembly is installed in the lower part of the chassis.

[0049] The chassis used in this example is based on the existing Lianzhi 8K commercial chassis in the market. In this example, two cold stacks are used in order to adapt to the chassis that requires greater cooling power (the purpose is to increase the power capacity of the cold stack, and the second is that under the same power capacity, the use of two cold stacks can be compared with the use of one cold stack. The effective heat dissipation area of the hot end of the cold stack is doubled, which is not only conducive to the heat dissipation of the hot end of the cold stack, but also conducive ...

Embodiment 2

[0055] image 3 is the method to implement this example. This example also takes the existing Lianzhi 8K commercial chassis in the market as a reference object.

[0056] This example also uses two cold piles (the purpose and function are the same as in embodiment 1) to adapt to the chassis that requires greater cooling power. The hot end of the cold pile uses a larger volume aluminum alloy radiator to improve heat dissipation. Adapt to some chassis that require a large cooling capacity. In this example, the power supply and cold source components of the whole machine are placed on the upper part of the chassis structure. The hot end radiators share a heat dissipation air circulation channel. Under the action of the large-diameter fan M1, the heat dissipation air required for the power supply and the hot end of the cold stack enters from the front of the upper part of the chassis and flows to the rear of the chassis to heat the power supply and the cold stack. The heat gener...

Embodiment 3

[0059] The applicant found through the production practice of the dust-proof and temperature-controlled chassis prototype: when the cold stack is working, the heat generated by its hot end is very large. In the general application of low-power cold stacks, the solid radiator with traditional metal alloy material structure can meet its Basic heat dissipation requirements, and in the use of relatively high-power cold reactors, solid radiators with traditional metal alloy material structures often cannot meet the harsh heat dissipation conditions of cold reactors, and cooling devices with appropriate volume and higher efficiency must be used. Timely dissipate the large amount of heat generated by the cold stack, otherwise the cold stack will not be able to operate normally for a long time. Based on this, in order to make the cooling of the computer with a larger power cold stack continue to work stably, this example uses a liquid-cooled radiator with a built-in micro-liquid pump w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com