Apparatus for forming groove used in cutting blade

A technology for cutting blades and forming devices, applied in broaching devices, broaching knives, milling equipment, etc., can solve the problems that square grooves cannot be accurately formed, cannot be accurately fixed, and are not provided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Referring now to the drawings, in which like reference numerals designate like or similar parts throughout the different views.

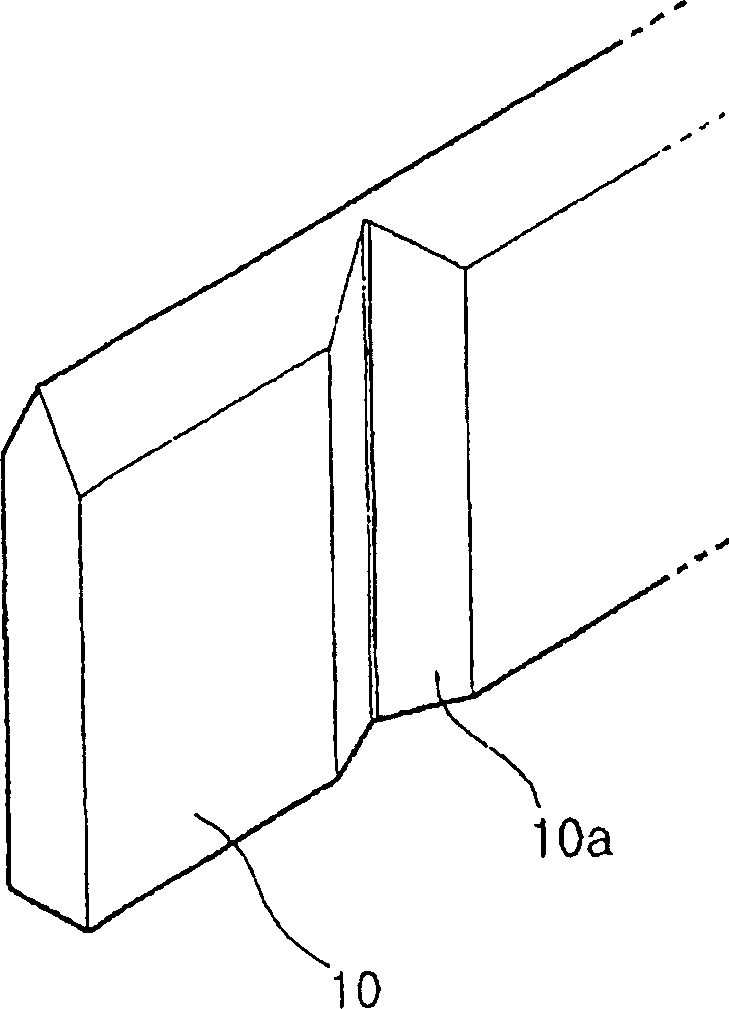

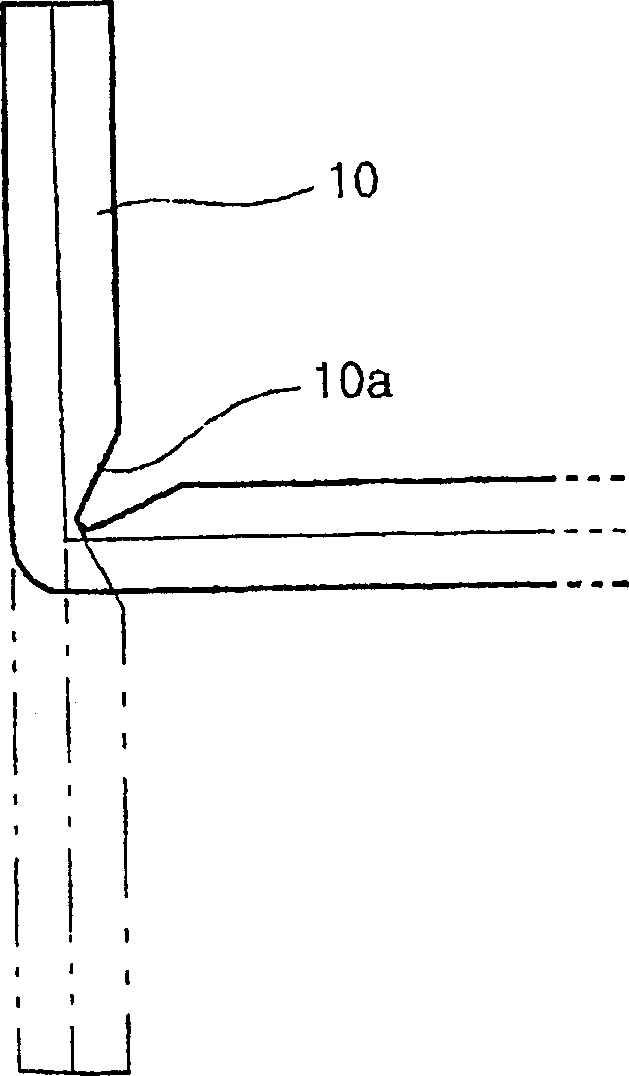

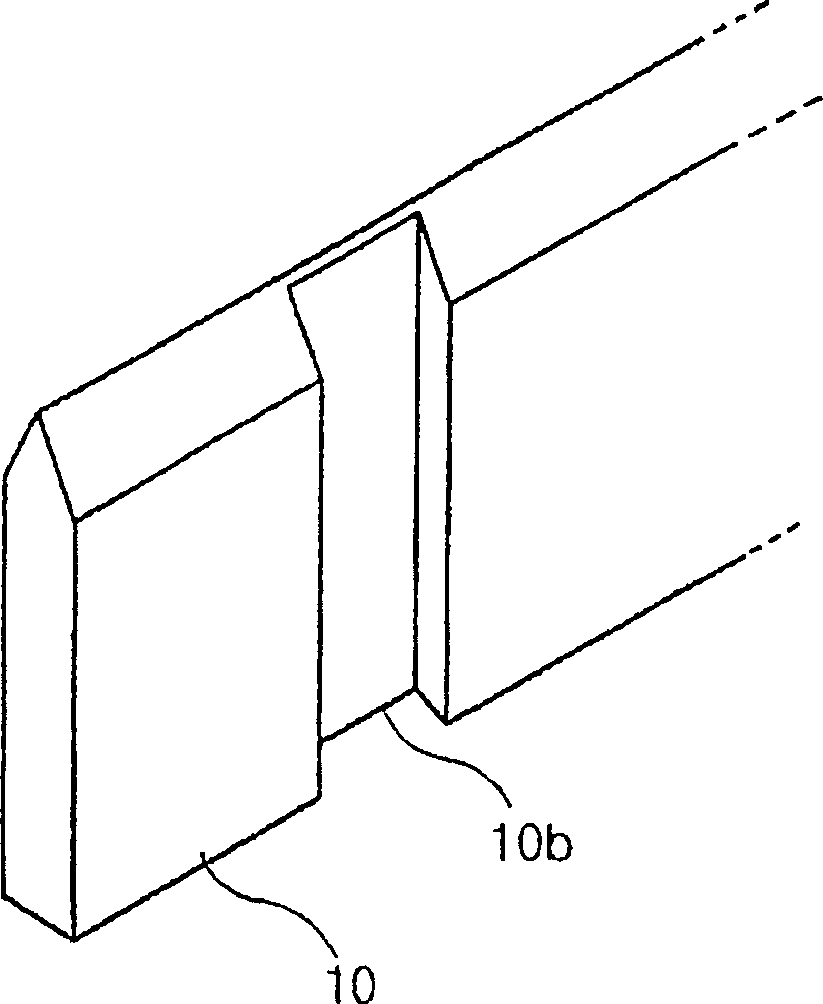

[0034] Figure 1a and 1b A cutting blade 10 is shown having a triangular groove 10a formed with the device of the invention and bent through 90° along this triangular groove 10a. Figure 2a and 2bA cutting blade 10 is shown having a square groove 10b formed with the device of the invention, and another cutting blade 10 is welded into this square groove 10b to form a T-shaped section.

[0035] Figure 3 to Figure 7 is a view for explaining an apparatus for forming a groove on a cutting blade according to the present invention suitable for forming the grooves 10a and 10b.

[0036] In the device for forming grooves in the blade, the cutting blade 10 passes between a pair of broaches 41 supported by tunnel-shaped guides (not shown) in the cutting blade forming device. That is, the device according to the present invention is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com