Method for preparing lecithin in high purity

A phosphatidylcholine, high-purity technology, applied in the direction of edible phospholipid composition, food science, protein food ingredients, etc., can solve the problems of easily polluting the environment, affecting the application of phosphatidylcholine products, and difficult to completely remove acetonitrile solvent, etc. Achieve the effect of cleaning the production environment, improving labor efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

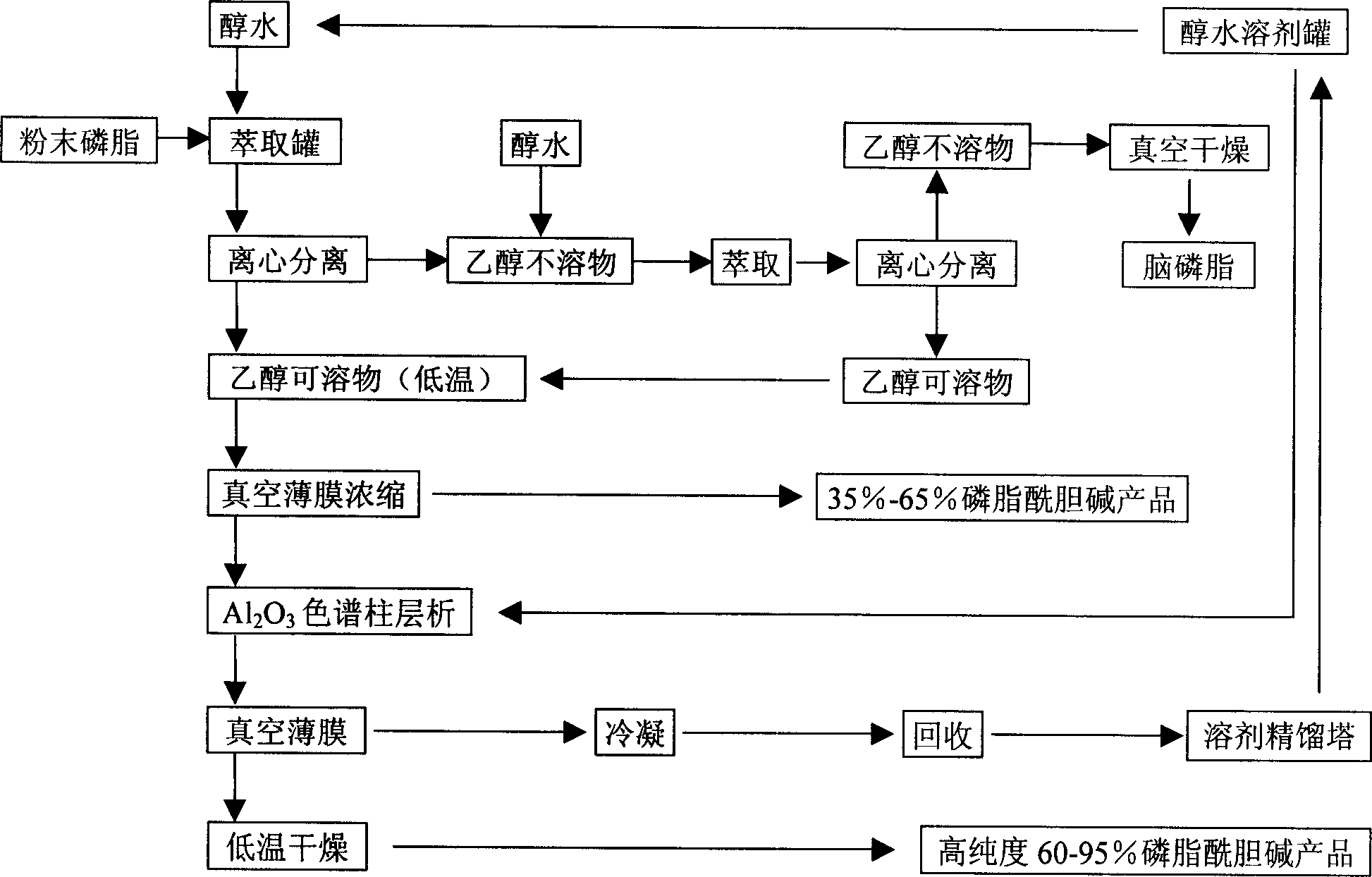

Method used

Image

Examples

Embodiment 1

[0016] Powder soybean lecithin raw material 20kg, add 100L of low-carbon alcohol-water mixed solvent (low-carbon alcohol: water is 90:10 volume ratio), mix and extract for 90 minutes, after centrifugation, add 100L low-carbon alcohol-water mixed solvent to the alcohol-insoluble matter , extracted for 60 minutes, and centrifuged. The alcohol-soluble matter was concentrated at a film centrifugal concentrator with a temperature of 70°C and a vacuum of 0.095mPa to obtain an alcohol concentrate. The mixed solvent of alcohol and water was used as the eluent for chromatographic separation. The eluent after chromatography obtained 4.62 kg of phosphatidylcholine product through vacuum concentration and drying for 240 minutes (75° C. of temperature, 0.096 Mpa of vacuum). The yield is 82.8%.

Embodiment 2

[0018] 10kg of powdered soybean lecithin raw material, add 20L of low-carbon alcohol-water mixed solvent (low-carbon alcohol:water is 98:2 volume ratio), extraction temperature is 30°C, mixed and extracted for 60 minutes, after centrifugation, add 30L to the alcohol-insoluble Low-carbon alcohol-water mixed solvent, extraction for 60 minutes, centrifugation, alcohol-soluble matter is concentrated in a thin-film centrifugal concentrator at a temperature of 75°C and a vacuum of 0.09MPa to obtain an alcohol concentrate, which is passed through an aluminum oxide chromatography column Chromatographic elution separation. The eluent after chromatography was concentrated and dried in vacuum for 210 minutes at a temperature of 80° C. and a vacuum of 0.096 MPa to obtain 3.05 kg of phosphatidylcholine product. The results of high-pressure liquid chromatography analysis showed that the content of phosphatidylcholine was 72.5 %, the product yield is 86.4%.

Embodiment 3

[0020] Powdered rapeseed oil phospholipid raw material 10kg, add 80L of low-carbon alcohol and water mixed solvent (low-carbon alcohol: water is 99:1 volume ratio), mix and extract at room temperature for 60 minutes, centrifuge, add 20L of low-carbon alcohol and water to the alcohol-insoluble matter and mix Solvent, extracted for 45 minutes, centrifuged, alcohol-soluble matter was concentrated in a thin film centrifugal concentrator with a temperature of 65°C and a vacuum of 0.095MPa to obtain an alcohol concentrate, which was separated by aluminum oxide chromatography column chromatography. The eluent after chromatography was concentrated and dried in vacuum for 240 minutes at a temperature of 75° C. and a vacuum of 0.098 MPa to obtain 2.55 kg of phosphatidylcholine product. The results of high-pressure liquid chromatography analysis showed that: phosphatidylcholine The content is 84.3%, and the product yield is 80.3%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com