Process for the manufacture of Er doped / Er, Yb codoping aluminium oxide optical wave guide amplifier

An optical waveguide amplifier and aluminum oxide technology, applied in lasers, laser components, optics, etc., can solve the problems of low cost performance and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

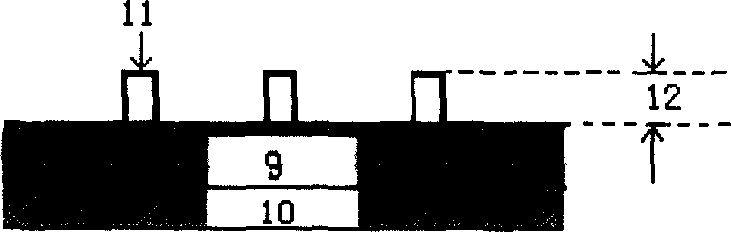

[0020] Step 1. Thermal oxidation of silicon substrate

[0021] In order to enable light waves to propagate in the thin film sample, the refractive index of the substrate needs to be lower than that of the thin film sample, usually by depositing a layer of SiO on a single crystal silicon wafer. 2 . In the experiment, thermal oxidation method was used to oxidize SiO with a thickness of about 600nm. 2 . The specific experimental process is as follows:

[0022] 1. Cleaning:

[0023] A. Clean with acetone and ethanol first, and then clean with ultrasonic wave for 5 minutes.

[0024] B. HF acid diluent cleaning.

[0025] C. Boil concentrated sulfuric acid for 3 minutes.

[0026] 2. Dry oxygen:

[0027] Put the monocrystalline silicon into the dry oxygen furnace and feed it with oxygen to heat it to make it react. The chemical equation of the reaction is Dry oxygen time 5 minutes.

[0028] 3. Wet oxygen:

[0029] After dry oxygen, there is a thin layer of SiO on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com