Square corrugated pipe

A bellows, square technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipes, etc., can solve the problems of increasing the vacuum capacity configuration, reducing the space utilization rate, small flexibility of the bellows, etc., and reducing the vacuum capacity. Configuration, improve space utilization, small spacing between pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

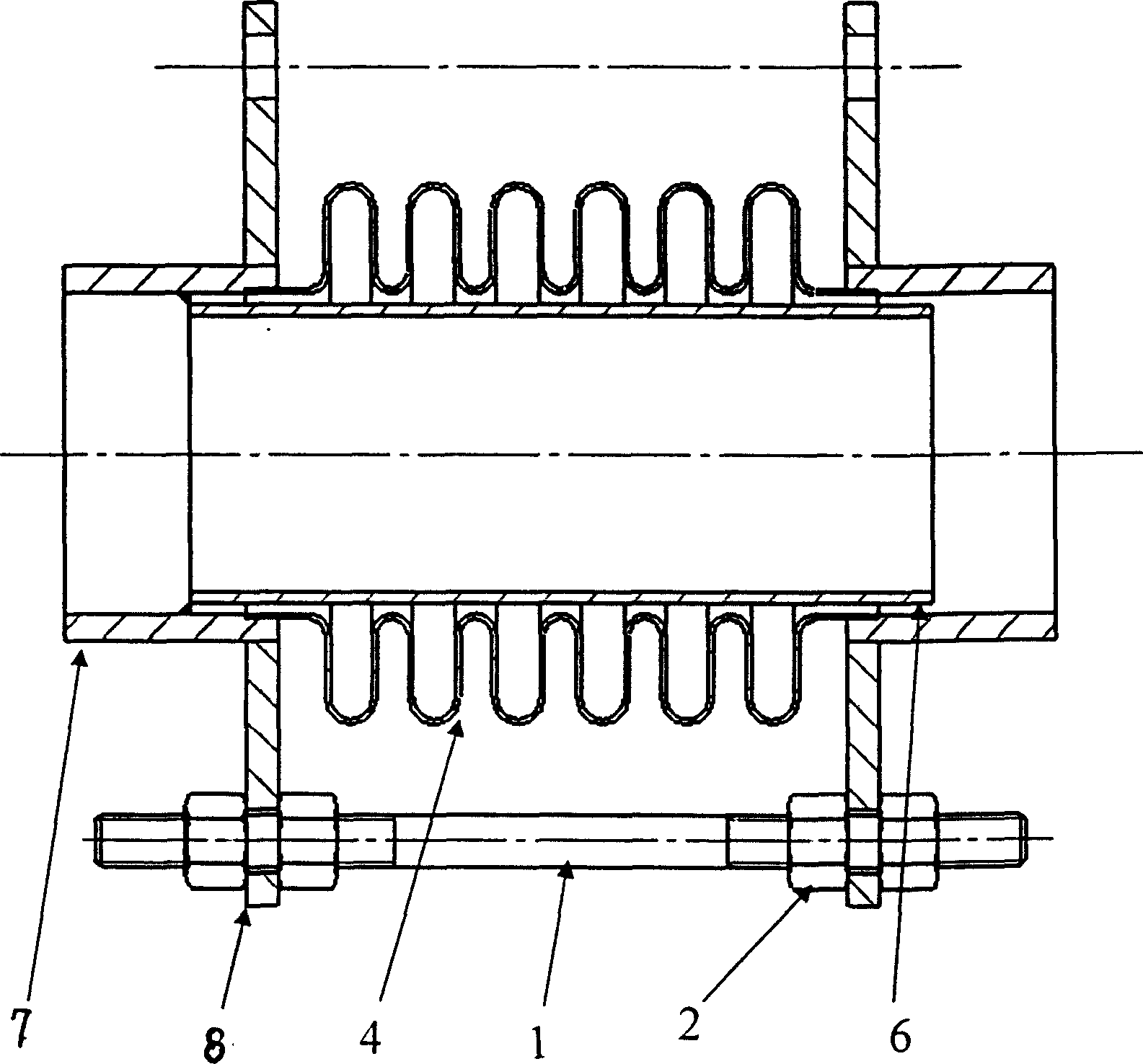

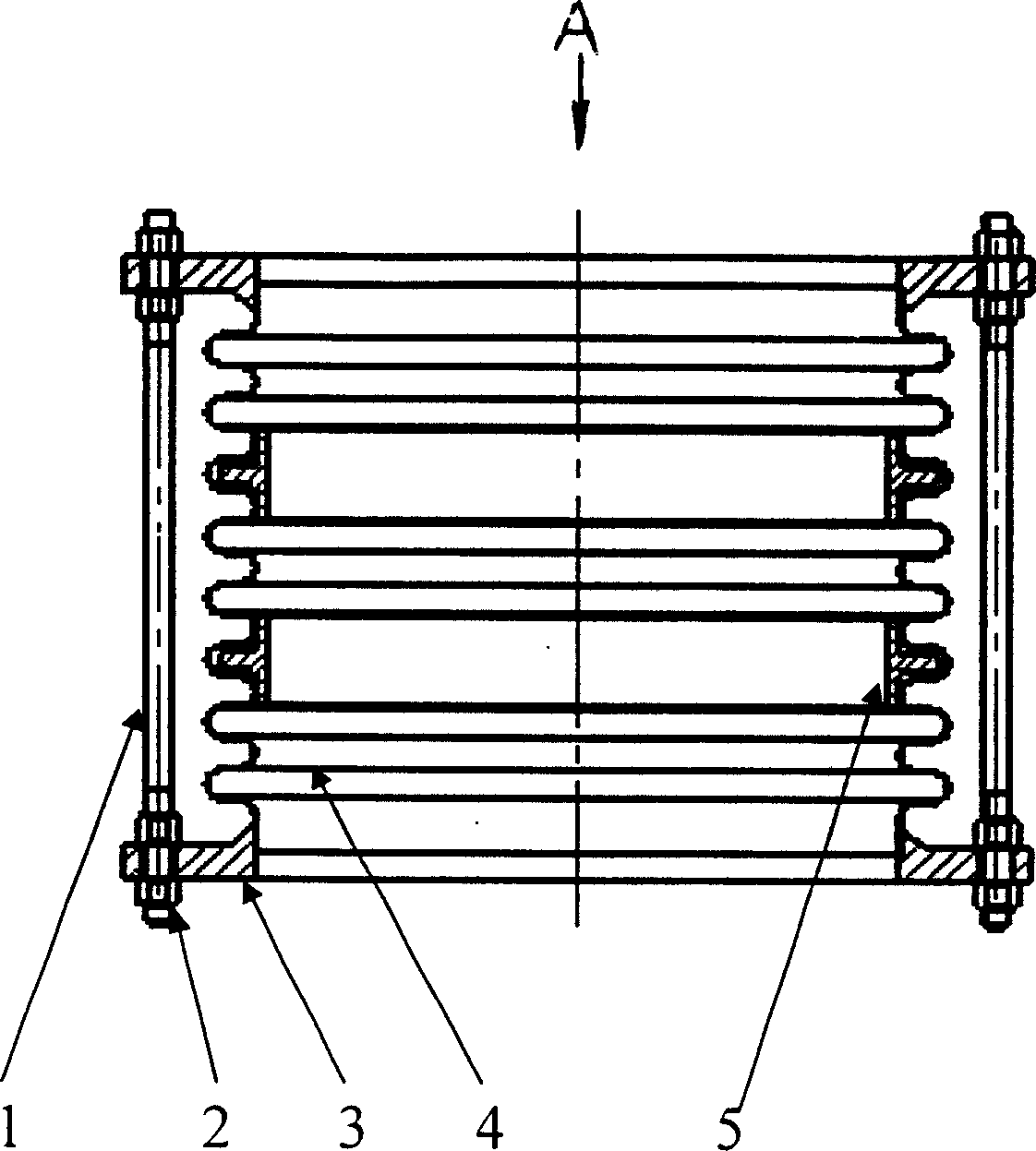

[0023] see figure 2 and image 3 As shown, the present invention comprises a bellows 4 , a positioning screw 1 and a nut 2 . The corrugated pipe 4 has a square pipe hole, and is a thin-walled pipe formed by pressing a stainless steel plate with a wall thickness of 0.3-0.6mm. Equidistant wave-shaped protrusions are arranged on the surrounding walls of the pipe, and the wave height is ≤10mm. The two ends are welded separately. Connecting flange 3 with identical pipe holes. T-shaped braces 5 are embedded in the inner troughs of the corrugated pipe 4, and there is a gap between the troughs provided with T-shaped braces 5 and the T-shaped braces 5, so it does not affect its axial expansion and contraction; and at intervals of 3 It is advisable to set one T-shaped brace 5 for ~6 waves, so that the corrugations between the T-shaped braces 5 can realize lateral displacement compensation and angular displacement compensation. Since the T-shaped brace 5 has a small twist and deforma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wave height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com