Surface acoustic wave element and method for fabricating semiconductor device

A surface acoustic wave and manufacturing method technology, applied to electrical components, impedance networks, etc., can solve problems such as low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

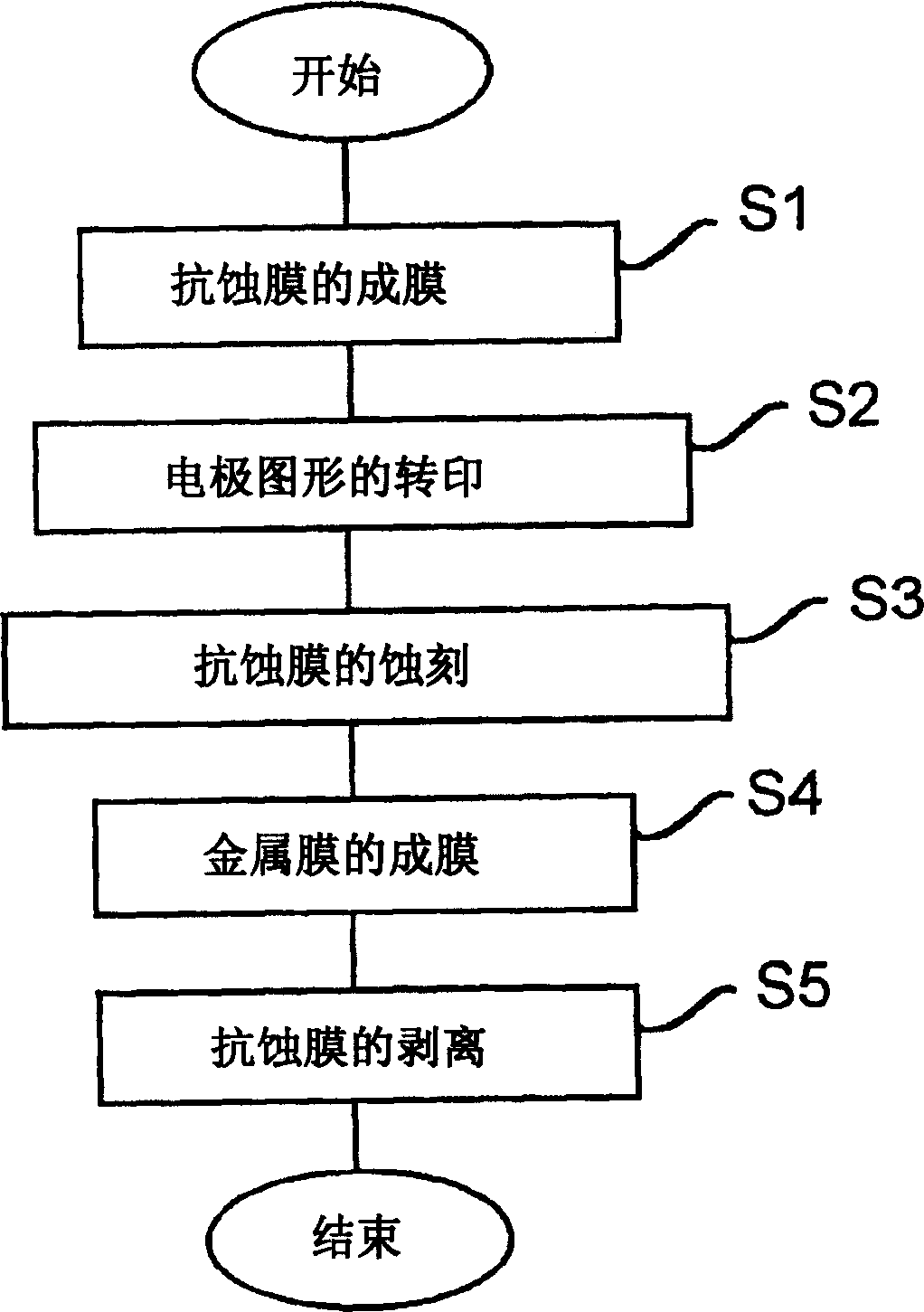

[0027] refer to figure 1 and Figure 2A ~ Figure 2F A method of manufacturing a surface acoustic wave element will be described.

[0028] First, if Figure 2A As shown, a flat resist film 2 is formed on the piezoelectric substrate 1 by the spin coating method (step S1). As the piezoelectric substrate 1, a single crystal piezoelectric substrate such as LiTiO3, LiNbO3, or crystal, a substrate on which an insulating film is formed, a substrate composed of a ceramic piezoelectric body such as PZT or PLZT, or a substrate laminated on a substrate can be preferably used. Thin film substrates such as diamond thin films and ZnO thin films.

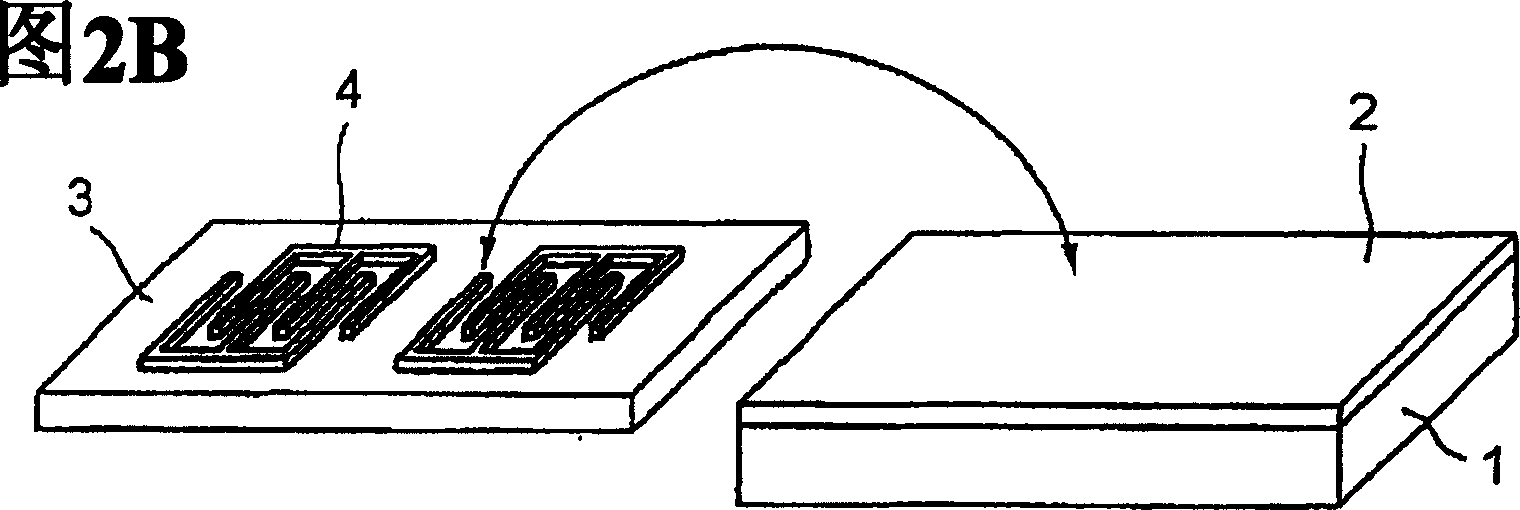

[0029] Next, as shown in FIG. 2B , the template 3 on which the curtain-like fine electrode pattern 4 is formed is pressed against the surface of the substrate 1 . In this way, if Figure 2C As shown, the curtain-shaped micro-electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com